Ademco - 650-650-6-650-12EX-651-651-6-651-12EX Passive Infrared Motion Detectors

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | ademco-650-650-6-650-12ex-651-651-6-651-12ex-passive-infrared-motion-detectors-2539018647.pdf |

|---|---|

| Type | |

| Size | 2.03 MB |

| Downloads |

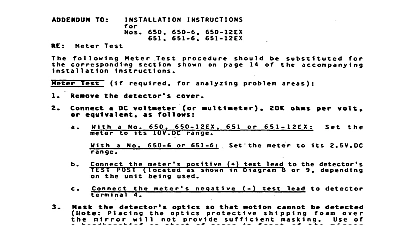

Text Preview

GENERAL INFORMATION Nos 650,650 S and 650 12EX provide 17 zones of wide angle coverage with range of up to 50 feet 152m 651,651 6 and 65 12EX offer 6 long range zones with reduced angle coverage up to 100 feet 30.5m models have the following features High precision computer designed parabolic optical system Dual element pyre electric sensor Precision die cast optical head for maximum RFI protection and accurate optical alignment Zone locator for clear visual ind ication of zone coverage Pre declined zones for fast and easy installation Separate pan and tilt control for convenient pattern adjustment to achieve desired coverage or avoid Zone direction not observable when cover is in place Wall corner mounting plate for fast and easy installation Full LED memory walk test night disable absent and thus provides AC supervision LED on Nos 650,651 will not be active when AC Nos 650 and 661 must be powered from the No 1319 plug in transformer included and contain a standby power supply The Nos 669 6,661 6,660 12EX require power from a 6V DC and 12V DC respectively that can provide at least 4 hrs of standby power Except as noted herein these fnstruc apply equally to the Nos 669,669 6,66942EX 661,661 6 and 66142EX the detector will operate at all times regardless of whether the control to which it is connected is or DISARMED Whenever and while motion is detected the unit LED will light and its relay con will transfer Alternatively when the detector is connected to a control that can provide a suitable voltage signal to indicate the control ARMED or DISARMED state the detector can be to provide optional modes of LED and relay operation See OPTIONAL MODES herein Detectors have an additional provision for use of an external LED which can duplicate remotely the indica of the detector built in LED OF OPERATION optical system divides the area into a series of protective zones A special sensor measures the level of infrared energy in each zone When an intruder crosses or enters any zone the resulting change in infrared is detected and an alarm condition will exist sensor does not respond to visible light or changes in the background temperature of the room a passive infrared device employs no transmission of any kind any number of units may be used in same area infrared energy does not penetrate most building materials even window glass so the unit responds only human movements inside the room CONSIDERATIONS AND TYPICAL LAYOUTS 656,65 6,65012u The pattern of protection provided by the 650 series Includes nine main zones which an angle of 75 five intermediate zones aligned in direction with alternate main zones but angled downward from the main zones and three downward zones aligned in the direction of the 2nd 5th 6th main zones completing entire pattern may be panned left or right up to 20 system has been designed to give proper coverage based upon a typical mounting height of 7 However the unit may be mounted at any height between 7 2 lm and 9 27m to achieve a proper 50 pattern pattern of protection See Diagrams 1 and 3 optical head may be tilted downward Combina Diagram 3 To adjust the tilt the unit is to be mounted higher than 9 2.7m perhaps as high as 12 3.7m or if it is desired to obtain a of less than 50 15.2m for a particular installation of mounting height and can be used to obtain coverages asshown the optical head grasp the metal casting firmly between thumb and index finger at both sides where a is provided pull gently forward until the assembly is free then set the tabs on the casting into the notches on the bracket and release See Diagram 2 IMPORTANT Do not touch the reflector or sensor 651,651 6 65 EXI The pattern of protection provided by the 651 series includes six zones positioned pattern which is ideal for the protection of hallways corridors or aisles pattern consists of a main zone two intermediate zones on either side of the main zone and angled below the main zone and three downward zones one aligned with and below the main zone two the outside and below the intermediate zones See Diagrams 4 and 5 entire pattern may be panned left or right up to 20 optical system has been designed to give proper coverage based upon the typical mounting height of 1 However the unit may be mounted at any height between 7 2 lm and 9 2.7m to achieve the proper 395m pattern See Diagram 5a the unit is to be mounted higher than 9 2.7m perhaps as high as 13 4.0m then the full range may be ob by tilting the optical assembly forward one notch using the method described above This will provide coverage for mounting heights between 10 3.0m and 13 4.0m See Diagram 5c Reduced range may obtained if desired by mounting the unit higher and aiming the optical assembly fully downward See 5s Zone Caution Note in Diagram 3 and 5 that for several tilt position mounting height combinations are indicated zones within which a person could be moving and not be detected by any of the coverage zones In general these dead zones are apt to be present between the intermediate and zones as the unit mounting height is increased and its coverage pattern is tilted downward a Mounting Location the Nos 650 and 651 Series Passive Infrared Detectors respond to changes in energy which occur an intruder moves into or out of a zone best coverage will be obtained if the mounting site is selected that the likely direction of intruder motion is ACROSS the pattern See Diagrams 6a b and c a hallway or aisle a No 651 series unit should be aimed directly down the center of the area the in zones will prevent an intruder from avoiding detection by following alternate approach is to angle the main zone from See Diagram 6e wall See Diagram 6d AND WIRING I R units are remarkably resistant to false alarm hazards but the following recommendations should observed locating unit where central heating radiators quartz or other radiant heaters live fires or ventilating could be within the protective zones locating the unit in direct sunlight or directly above strong sources of heat locating unit on unstable surfaces Be careful during installation or adjustment NOT TO TOUCH THE REFLECTOR OR SENSOR WHEN POSITIONING THE HEAD ASSEMBLY GRIP THE DIE CAST BODY ONLY AS SHOWN IN 2 Mount the wall plate to a firm and vertical surface flat on wall or in corner at the recommended height see section Orient the plate so that its unit mounting hooks are at the bottom If wiring is provided a hole in the mounting surface center the mounting plate with the bottom of the plate just above the This will aiign the wires with the wiring entry in the case when the unit is secured See Diagram 7 Remove front cover by loosening the retaining screw Push the two special hex head screws provided through the two retainer type mounting holes at rear of the case if this has not already been done Attach unit to wall plate as follows Engage lower hooks on wall plate into case bottom see Diagram 7 secure unit to wall plate with the two hex head screws provided Note Move detector head left or right gain access to screws Do not remove detector head from unit as damage to mirror may result For recessed mounting the No 659MK Flush Moun Kit is available Follow the instructions accom it a Mounting Location I 1 PROTECTION ZONES 650,650 6,650 12EX