Ademco - 972 Latching Monitors (6v and 12v)

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | ademco-972-latching-monitors-6v-and-12v-9760152438.pdf |

|---|---|

| Type | |

| Size | 1.43 MB |

| Downloads |

Text Preview

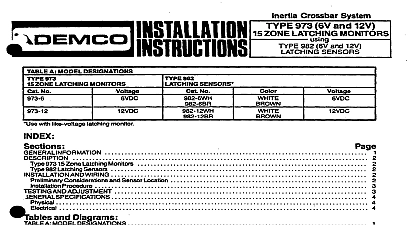

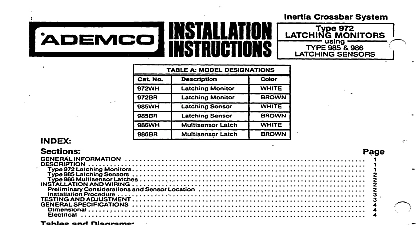

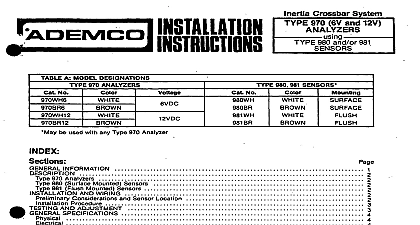

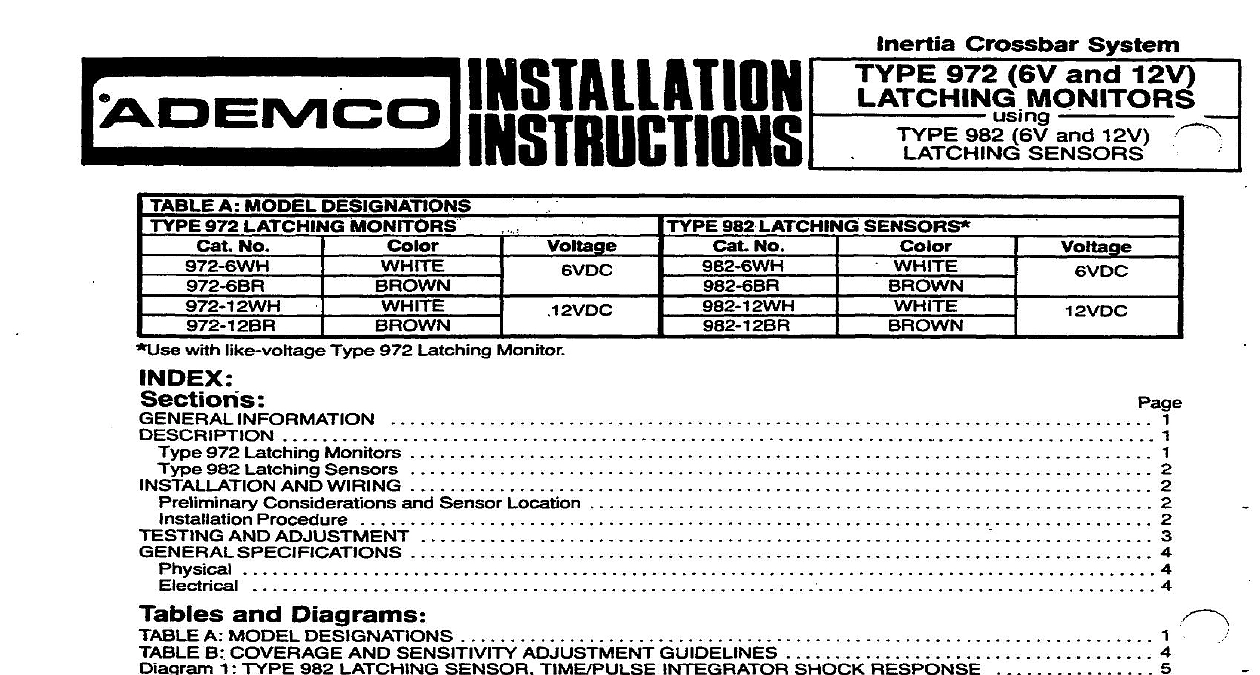

TABLE A MODEL DESIGNATKINS TYPE 972 LATCHING MONITORS No 2BR 982 LATCHlNG SENSORS No 2WH 2BR with like voltage Type 972 Latching Monitor INFORMATION AND WIRING 1 1 2 2 3 4 Considerations and Sensor Location AND ADJUSTMENT 4 4 SHOCK RESPONSE and Diagrams A MODEL DESIGNATIONS 1 4 6 COVERAGE AND SENSITIVITY ADJUSTMENT GUIDELINES 5 1 TYPE 982 LATCHING SENSOR TIME PULSE 5 DETAILS 2 TYPE 962 LATCHING SENSOR 6 4 FIELD CONNECTIONS WITHOUT SEPARATE TAMPER LOOP 7 5 FIELD CONNECTIONS WlTH SEPARATE TAMPER LOOP 6 INFORMATION Inertia Crossbar System Type 972 Latching Monitors accommodate any quantity of like voltage Type 962 Latching although a maximum of 30 is recommended for ease of servicing The resultant forced entry shock detection can be used alone or can complement other forms of perimeter protection The system possesses the ability to attacks before an intruder gains entry to the premises sensor sensitivity can be individually set and will respond to blows applied to the surface area that it protects A of small shocks a smaller number of larger shocks or a single gross attack will trip and latch the sensor and in trip and latch the monitor and place it in alarm A fault in the sensor loop will also trip the monitor A lit LED on the and on each tripped sensor indicates that an alarm has occurred monitor alarm contacts can be connected to any alarm panel possessing a closed circuit loop Reset is accom by interrupting 6V Type 972 Latching Monitors require 6VDC 66 ma for their operation The 12V models require 12VDC 40 ma drain is not dependent on the quantity of sensors connected where otherwise indicated the information contained herein applies to 6V and 12V latching monitors and sensors 972 Latching Monitors monitor is furnished in a tampered housing containing an LED visible through the unit cover an alarm relay and for connection of a Two wire supervised sensor circuit with end of line resistor b separate tamper loop if c protective circuit the unit closed contacts open during alarm and d 6VDC power or lPVDC as required a sensor trip level is reached and the monitor in tttrl rips the monitor alarm contacts will open and its LED will The unit will remain thus in alarm until reset by momentary interruption of power monitor power momentarily processing circuit which has been designed for optimum response to inertia crossbar assembly A high inertia mass is mounted on a highly polished 982 Latching Sensors sensor tampered housing contains a shock sensing module a level sensitivity adjustment potentiometer terminals for connection of the two wire end of line resistor supervised sensor loop and if required a separate loop The housing is designed for surface mounting An LED is visible through its cover sensor contains a at forced entry through most building materials See Diagram 1 The alarm trip level is reached after the sensing a succession of light shocks e g gentle prying of a door or window or a smaller number of heavier shocks e g hit or pounding on the building structure Agross attack very large single shock including breaking of glass or fault the sensor loop will trip the system immediately The time pulse integrator circuit provides good immunity to lower occasional shocks such as may be caused by building expansion on contraction or other transient occurrences sensing module may be rotated up to 180 about its axis to facilitate mounting on a vertical hcrizontal or sloping sur and to enable sensor operation in a NORMAL or DAMPED mode depending upon range desired characteristics the mounting surface and other field conditions See Diagram 2 the heart of the sensing mod is plated which straddles four other highly polished gold plated elements in such a manner as to provide two paths for the sensor circuit current with two sensing contact points in each path Optimum long term stability and are provided by this multiple path arrangement entry attempts typically produce vibrations which affect the contact points of the sensing module inertia crossbar The resultant tiny and rapid variations in sensor circuit current are then processed by the sensor time pulse If a series of shocks of sufficient intensity is sensed the trip level will be reached the unit will trip and its LED light steadily The monitor will in turn signal the alarm to the protective system control AND WIRING Considerations and Sensor Location of the many types of building materials and construction methods used it is impossible to give precise sensor information for any shock system but Table B gives general guidelines as to the diameter of protection DP that be obtained under ideal conditions for each sensor when mounted on various materials and adjusted as shown number of sensors may be connected to a single monitor but a maximum of 30 is recommended ease of servicing The diameter of protection DP may be smaller where there are discontinuities in the mounting surface such windows doors wrners or joints between panels or cracks In these cases the sensors should be mounted at l 2 from the center of the gap See Diagram 4 a b c d Where the opening exceeds the DP use sensors around the as shown in Diagram 4 e better operation Locate sensors at the most likely intrusion height relative to outside ground level Where the height of a wall 1 l 2 DP use two rows staggered as shown in Diagram 4 f Sensors on surfaces below outside gr nd Loose or rattling surfaces may dive false shock signals In particular check windows for loose frames or pan