Autocall Sounder Base A4098-9794 for use with TrueAlarm Photoelectric and Heat Sensors

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | autocall-sounder-base-a4098-9794-for-use-with-truealarm-photoelectric-and-heat-sensors-5361240978.pdf |

|---|---|

| Type | |

| Size | 799.28 KB |

| Downloads |

Text Preview

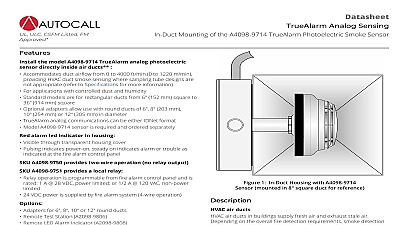

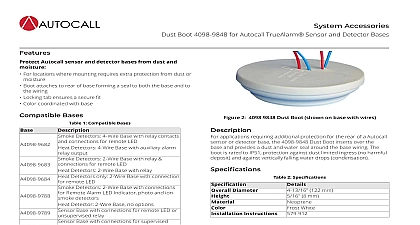

Datasheet Analog Sensing Base A4098 9794 for use with TrueAlarm Photoelectric and Heat Sensors ULC CSFM Listed FM TrueAlarm sensor base with built in electronic alarm Piezoelectric sounder provides high output 88 dBA with low current 20 mA separately For use with interchangeable TrueAlarm photoelectric or heat sensors Operation is for ceiling or wall mounting operation details Powered from 24 VDC or from a compatible Notification Appliance NAC Synchronized via communications or by the NAC if NAC powered Sounder can be manually activated from the control panel Sensor and sounder operation is listed to UL Standard 268 Sounder operation is also listed to UL Standard 464 as an audible appliance analog sensing operation Analog sensor information is digitally communicated to the control via IDNet two wire communications Sensor information is processed by the control panel to determine status use with the following Autocall products 4007ES 4010ES 4100ES and 4100U Series control panels features Louvered smoke sensor design enhances smoke capture by directing to chamber entrance areas are minimally visible when ceiling Designed for EMI compatibility Magnetic test feature is provided Optional accessories include remote LED alarm indicator and output base reference For standard bases refer to data sheet AC4098 0019 For isolator bases refer to data sheet AC4098 0025 For photo heat sensors refer to data sheet AC4098 0024 single and AC4098 0033 dual address Total quantity of sounder bases available for coding on the communications channel may vary with panel application and of NAC power Refer to specific control panel requirements Analog Sensing Description bases combine an audible notification appliance and a analog sensor to provide Communication of Analog Sensing Sensors provide an measurement that is digitally communicated to the control panel it is analyzed and an average value is determined and stored alarm or other abnormal condition is determined by comparing the present value against its average value Data Evaluation Monitoring each sensor average value a software filtering averaging process that compensates environmental factors dust dirt etc and component aging an accurate reference for evaluating new activity The result a significant reduction in the probability of false or nuisance alarms by shifts in sensitivity either up or down Panel Selection Peak activity per sensor is stored to assist evaluating specific locations The alarm set point for each TrueAlarm is determined at the control panel selectable as more or less as the individual application requires Selection Alarm set points can be programmed timed automatic sensitivity selection such as more sensitive at night sensitive during day Control panel programming can also provide operation per sensor For example a 0.2 level may cause a to prompt investigation while a 2.5 level may initiate an alarm Alarm and Trouble LED Indication Each sensor base LED to indicate communications with the panel If the control panel that a sensor is in alarm or that it is dirty or has some other of trouble the details are annunciated at the control panel and that base LED will be turned on steadily During a system alarm the panel will control the LEDs such that an LED indicating a trouble return to pulsing to help identify the alarmed sensors Sounder Base Features mounted address selection allows the address to remain with programmed location when the sensor is removed for service or type Access is from the front under the removable sensor sensor type identification provides default sensitivity substituting sensor types Different sensor types can be easily to meet specific location requirements This feature also intentional sensor substitution during building construction conditions are temporarily dusty instead of covering the smoke causing them to be disabled heat sensors may be installed reprogramming the control panel red LED indicates power on by pulsing or alarm or trouble steady on The exact status is annunciated at the fire alarm control alarm control panel provides Peak value logging allowing accurate analysis of each sensor for sensitivity selection Sensitivity monitoring satisfying NFPA 72 sensitivity testing automatic individual sensor calibration check verifies integrity Automatic environmental compensation multi stage alarm operation display of sensitivity directly in percent per foot Ability to display and print detailed sensor information in plain English 1 Photoelectric Sensor in Sounder Base A4098 9794 This product has been approved by the California State Fire Marshal CSFM pursuant to Section 13144.1 of the California Health and Safety Code See CSFM Listings 7300 2269 0531 7270 2269 0512 7272 2269 0537 and 7300 2269 0551 for allowable values and or conditions concerning material presented in this document Additional listings may be applicable your local product supplier for the latest status Rev 13 03 2021 Base A4098 9794 for use with TrueAlarm Photoelectric and Heat Sensors LED Annunciation Relay activates when base LED is on indicating a local alarm or trouble Contacts are DPDT rated 2 30 VDC 1 2 A 120 VAC for transient suppressed loads requires 24 VDC coil power Remote red led Alarm Indicator mounts on a single box to provide status indications where the sensor location may be readily visible 3 Photoelectric Sensor with Sounder Base Heat Sensor heat sensors are self restoring and provide rate fixed temperature sensing selectable with or without temperature sensing Due to its small thermal mass the accurately and quickly measures the local temperature for at the fire alarm control panel temperature detection is selectable at the control panel for 15 F 8.3 C or 20 F 11.1 C per minute Fixed temperature is independent of rate of rise sensing and programmable to at 135 F 57.2 C or 155 F 68 C In a slow developing fire temperature may not increase rapidly enough to operate the rate feature However an alarm will be initiated when the temperature its rated fixed temperature setting heat sensors can be programmed as a utility device to for temperature extremes in the range from 32 F to 155 F 0 to 68 C This feature can provide freeze warnings or alert to HVAC problems Refer to specific panels for availability 4 Heat Sensor A4098 9794 Sounder Base In most fires hazardous levels of smoke and toxic gas build up before a heat detection device would initiate an alarm In where Life Safety is a factor the use of smoke detection is highly Reference locations should be determined after careful consideration the physical layout and contents of the area to be protected Refer NFPA 72 the National Fire Alarm and Signaling Code On smooth smoke sensor spacing of 30 ft 9.1 m may be used as a guide detailed application information refer to A4098 Detectors Sensors Bases Application Manual Part Number 574 709AC For detailed application information including sensitivity selection to Installation Instructions 574 709AC 2 Remote LED Alarm Indicator Analog Sensor Features against rear air flow entry are EMI RFI shielded sensors Selectable rate compensated fixed temperature sensing with or rate of rise operation Rated spacing distance between sensors Temp F 57.2 C 60 ft x 60 ft ULC F 68 C m ft x 40 ft m Spacing Either Fixed Setting ft x 20 ft 6.1 m for fixed only RTI Quick ft x 50 ft 15.2 m for fixed with either rate of rise RTI Ultra Fast Sensors Photoelectric technology sensing 360 smoke entry for optimum response Built in insect screens Photoelectric Sensor photoelectric sensors use a stable pulsed infrared LED source and a silicon photodiode receiver to provide consistent accurate low power smoke sensing Seven levels of sensitivity are for each individual sensor ranging from 0.2 to 3.7 per foot