DSC PGx935 Shock Sensor - Installation Guide - EN-FR-ES-PO

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | dsc-pgx935-shock-sensor-installation-guide-en-fr-es-po-2504786193.pdf |

|---|---|

| Type | |

| Size | 3.27 MB |

| Downloads |

Text Preview

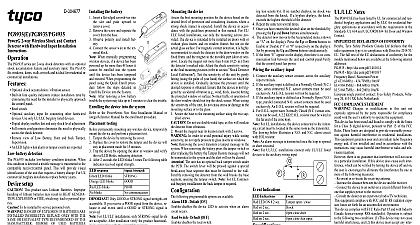

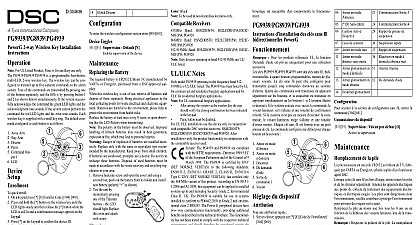

D 304677 2way Wireless Shock and Contact with Hard wired Input Installation PGx935 Series are 2way wireless magnetic contacts with shock detector and auxiliary input The PGx935 fits doors walls or roofs and is ideal for residential or installations It detects and analyzes a series of low shocks up to 10 low level shocks within 30 seconds and early warning of any attempt of intrusion prior to Optional shock vibration sensor Built in link quality indicators reduce installation time by the need for the installer to physically the control panel Reed switch with a magnetic anti masking sensor Optional auxiliary input for connecting other hardwired Use only UL ULC burglary listed devices Digital display enables fast and easy shock level adjust Full remote configuration eliminates the need to physically the shock detector Remote view of Low Battery front and back Tamper An LED lights whenever alarm or tamper events are Detection PGx935 includes low battery condition detection When condition is detected a trouble message is transmitted to the receiver control panel This will provide visual of the unit that requires a battery change For UL burglary installations replace battery yearly Setup product uses Lithium Batteries Improper handling of lith batteries may result in HEAT GENERATION EXPLO or FIRE which may lead to personal injuries To be installed by service persons OF EXPLOSION BATTERIES ARE INCORRECTLY REPLACE ONLY WITH THE OR EQUIVALENT TYPE RECOMMENDED BY MANUFACTURER DISPOSE OF USED BATTERIES TO THE MANUFACTURER INSTRUC AWAY FROM SMALL CHILDREN IF SWAL PROMPTLY SEE A DOCTOR not try to recharge these batteries Battery replacement should be done by installer For use indoor non hazardous locations only To ensure the continued operation of all wireless devices performing a system default a global upload of all wire programming via DLS is recommended before defaulting system After completing the system default download the programming B H F Auxiliary input terminals Back tamper switch Battery clips Back tamper break away segment Digital display Front tamper switch Enroll button LED Reed switch Up and down buttons LED Reed switch on underside of PC Board in unit on side of the case indicates location of reed switch Magnet 1 4 space maximum 6mm 2.2 k resistor N C switch N O switch the battery Insert a flat edged screwdriver the slot and push upward to cover Remove the screw and separate cover from the base Observe polarity and install bat Connect the sensor wire to the ter block When manually programming devices if a device has been up for more than 48 hours it be enrolled into the system the device has been tampered restored When programming the using the Quick Enroll proce follow the steps detailed in the Device into the System After restoring a low battery trouble the system may take to 5 minutes to clear the trouble the Device into the System quick enroll On a keypad press 8 Installer Code 804 000 Press and hold the device enroll button until the LED lights and then release the enroll button while the LED is lit A confirmation message then appears on the keypad Press key to confirm ID Enter 3 digit zone Enter 3 digit zone type Enter 1 digit partition for all desired partitions and press If using an LCD keypad you can scroll to the desired and press to toggle the partition On an LCD keypad enter the label by using word library pre enroll Remotely configure the unique ID number into the system more information see the HSM2HOST manual When on site press the device enroll button If the wireless device has been powered for more then 48 without being enrolled tamper and restore the device to it Testing permanently mounting any wireless device temporarily the device and perform a placement test Tamper the device by removing the cover Replace the cover to restore the tamper and the device will in placement mode for 15 minutes Trip the device by opening the door or window and verify red LED blinks indicating detection After 2 seconds the LED blinks 3 times The following table received signal strength Strength communication response LED blinks LED blinks LED blinks blinks Only GOOD or STRONG signal strengths are If you receive a POOR signal from the device re it and re test until a GOOD or STRONG signal is For UL ULC installations only STRONG signal levels acceptable After installation verify the product functional in conjunction with the compatible receivers HSM2HOST9 HS2ICNRF P 9 and PG9920 For detailed placement instructions refer to the control Reference Guide Separation the reed switch Input Default N the external input on a shock sensor Default Y supervision of the device Accumulation Default N the integration mechanism for detec of weak shock Zone EOL Default 01 auxiliary input as one of the following Disabled Single EOL 02 Normally Normally Sensor Threshold Default 08 the two digit threshold from 01 very weak strong Detector Local Calibration PGx935 can only be locally calibrated when the device is Local Diagnostics mode first 15 minutes after opening the To calibrate when not in local diagnostics mode reset device by closing the tamper switch Disable the accumulation parameter while testing the If after activating the display no buttons are pressed 20 seconds the display turns off Turn on the digital display by pressing the Up or Down but The letter appears for 3 seconds then a menu you to select the threshold from a range of 1 19 If letter appears there is no communication link the unit and control panel and no changes shall be Change the threshold by pressing the Up or Down button lower the threshold the higher the sensitivity Use the thresholds for harder materials such as concrete For aid in selecting a threshold while the menu is active on the surface with the required force to trip the The power of the detected knock will be presented the display as a blinking number for 3 seconds The num should be in the range of 1 to 19 where 1 is very weak higher sensitivity and 19 is very strong requir less sensitivity If no number displays no shock was from the knock If a hyphen displays the knock the highest threshold of the detector Repeat the same test several times Once you have entered the desired value set the threshold by the Up and Down buttons simultaneously The detector now moves to the Accumulated menu shown on the display Press the Up or Down buttons to or Disable or respectively on the display by pressing the Up and Down buttons simultaneously If the letter appear on the display then there is no com link between the unit and control panel Verify the control panel has power Input wiring Connect the auxiliary sensor contacts across the auxiliary terminals the auxiliary input is defined as a Normally Closed type series connected N C sensor contacts must be exclusively An E O L resistor will not be required the auxiliary input is defined as a Normally Open N O parallel connected N O sensor contacts must be used An E O L resistor will not be required E O L supervision Normally Closed N C sensor can be used A 2.2K E O L resistor must be at the far end of the zone loop For UL installations the device connected to the initiat circuit must be located in the same room as the transmitter drawing below illustrates a N O and N C alarm circuit E O L resistor An alarm message is transmitted once the loop is opened short circuited of of Magnet X Y Z Ferrous