Edwards 101XBRM Series Instructions

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | edwards-101xbrm-series-instructions-9025167438.pdf |

|---|---|

| Type | |

| Size | 1.20 MB |

| Downloads |

Text Preview

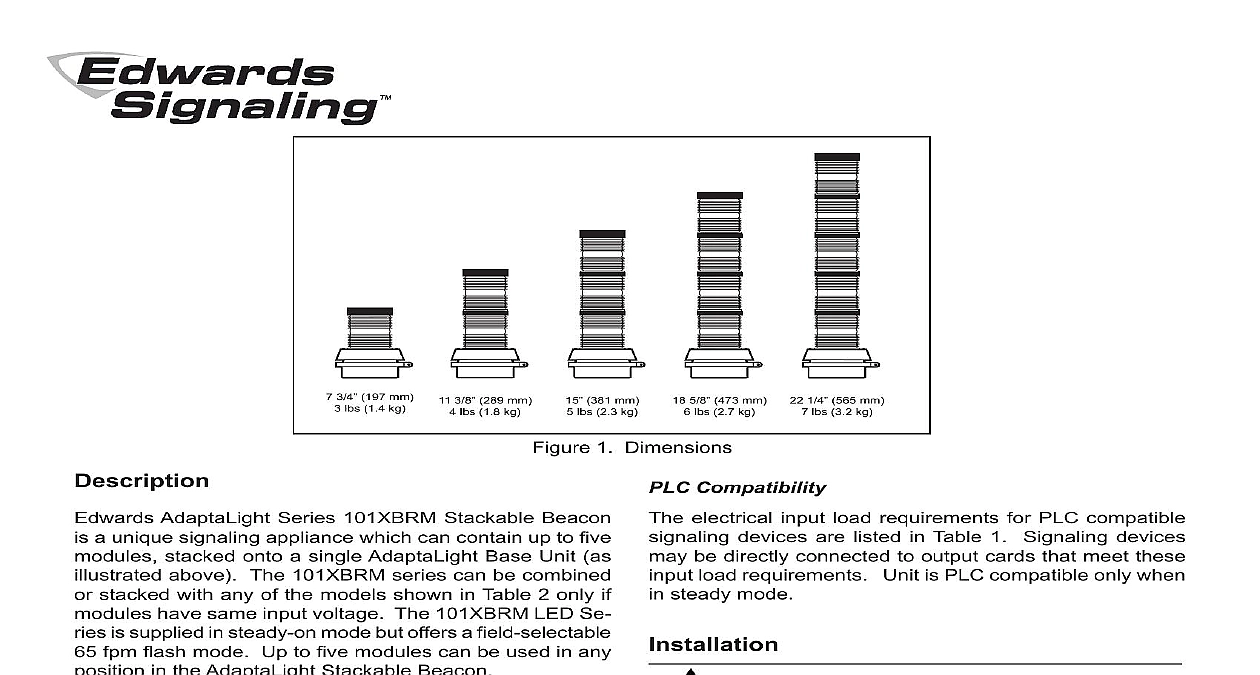

7 3 4 197 mm lbs 1.4 kg 3 8 289 mm lbs 1.8 kg 381 mm lbs 2.3 kg 5 8 473 mm lbs 2.7 kg 1 4 565 mm lbs 3.2 kg 1 Dimensions AdaptaLight Series 101XBRM Stackable Beacon a unique signaling appliance which can contain up to five stacked onto a single AdaptaLight Base Unit as above The 101XBRM series can be combined stacked with any of the models shown in Table 2 only if have same input voltage The 101XBRM LED Se is supplied in steady on mode but offers a field selectable fpm flash mode Up to five modules can be used in any in the AdaptaLight Stackable Beacon AdaptaLight base unit 101BS contains a mini pulsating rated 85 dB at 10 feet 3.05 m This horn can operate a sixth independent signal or with any one of the stacked shown in Table 2 The base unit has a screw type strip for positive hard wiring Each module in the is electrically interconnected through solid copper and mating contacts to withstand vibration Each is connected to the one below it by a solid through for mechanical integrity is UL and cUL listed for direct surface or pipe in non hazardous dust and outdoor applications AdaptaLight may be mounted vertically with lenses facing or with lenses facing down on ceiling The AdaptaLight not suitable for outdoor installations when mounted with lenses facing down The AdaptaLight must never be horizontally Assemble and install in accordance these instructions AdaptaLight modules have double fresnel polycarbonate available in a variety of colors each providing a 360 light pattern Specifications Locations Ratings 31F to 150F 35C to 66C Compatibility electrical input load requirements for PLC compatible devices are listed in Table 1 Signaling devices be directly connected to output cards that meet these load requirements Unit is PLC compatible only when steady mode prevent electrical shock do not connect until instructed to do so equipment must be installed by a qualified electrician in with the latest edition of the National Electrical and applicable local codes Mount the base vertically either facing up or down using of the following procedures Figures 2 and 3 For indoor applications the base may be direct mounted mounted on a 4 102 mm box or mounted on 1 2 NPT conduit outdoor weatherproof applications the base be conduit mounted vertically facing up Loosen the screw in the clamp ring remove ring and aside A permanently affixed gasket is supplied on the Use care when handling the base unit to tearing of the gasket Phone 800 336 4206 Fax 800 454 2363 3101631 ISSUE 3 2010 No 24D 120A AC volts at 50 60 Hz DC AC DC AC 1 PLC Compatibility off state current mA on mA inrush duration A millisecond A millisecond A microsecond A microsecond Direct Surface Mounting indoor installation only the two knockouts from the bottom of the the base to the surface using suitable not supplied 4 102 mm Octagon Box Mounting indoor only the two knockouts from the bottom of the the base to the octagon box not supplied by the screws supplied with the box through knockout holes in the base Conduit Mounting indoor or outdoor installation a 1 2 NPT conduit not supplied Align the entrance hole on the base with the conduit rotate base until base is tightly secured Route incoming field wiring into the base through the entrance hole to five 101XBRM LED modules or any other modules in Table 2 can be used in any position in the stack terminal block labels 1 through 5 correspond to the modules with 1 being the bottom module on the field wiring to the terminal block as shown in 4 Ground the AC AdaptaLights to the grounding screw 3 in accordance with applicable codes Place connected wires inside of the base the base unit and place the base gasket on as shown in Figure 2 To stack the modules align the notch on the bottom of first module with the notch on the base and press position Secure by tightening the slotted panhead located on the top of the module Never try to remove the through bolt from the the 8 32 x 3 8 9.5 mm plastic panhead in the side of the module lens Figure 5 gasket supplied with module onto the top of module 3101631 ISSUE 3 adding modules in this manner as required the cap supplied with the base unit onto the top ensuring the gasket is in place Secure with o ring and 3 8 9.5 mm cap screw supplied Turn on power and verify that module s and horn operating properly Pattern Change to Specifications for replacement parts prevent electrical shock disconnect all before starting work on unit Remove the 3 8 9.5 mm cap screw o ring and cap top of unit Remove the 8 32 x 3 8 9.5 mm plastic panhead screw the side of the module lens Loosen the slotted panhead through bolt on top module not remove the through bolt from the module turn bolt approximately 30 turns Carefully remove the module and gasket Continue to disassemble until the internal dipswitch on top circuit is reached or the component to be replaced located To change the flash pattern set the dipswitch illustrated in Figure 6 To replace the pulsating horn instructions shown below Replace mini pulsating horn Remove the screw in the clamp ring remove ring set aside Remove three phillips head screws from top of base and the base horn assembly from the top portion the base Figure 2 Remove the phillips head screw securing the horn the mounting bracket Figure 2 Disconnect wires by cutting off the wire crimp Secure the new horn on the mounting bracket with screw removed in step 6 c Connect wires using wire nuts not supplied It is not necessary disassemble this portion the unit for installation ring Skirt Unit x 7 8 Phillips head screw 2 Catalog Series 101BS AdaptaLight Base Unit Assembly Mounting Surface Mounting or without 4 octagonal back box mount hole NPT Conduit supplied Knockouts for Surface Mounting 3 Mounting the Catalog Series 101BS AdaptaLight Base Unit 3101631 ISSUE 3 AdaptaLight module lens surfaces should be periodically and cleaned with a dry soft clean cloth to maintain light visibility If necessary the outer lenses may cleaned with water and a mild detergent on a well rung soft clean cloth Incandescent Light Unit DC Color AC DC AC LED Units DC DC Incandescent Light Unit AC AC Strobe Light Unit DC DC Color Color DC DC Color in catalog number e g 101SINHR N5 signifies halogen 2 Stackable Light Units Available 3101631 ISSUE 3 installed copper conductors from 1 thru 5 to contact points installed wire leads with Unit screw or