Edwards 5520 & 5521 Series Installation Instructions

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | edwards-5520-5521-series-installation-instructions-8794062531.pdf |

|---|---|

| Type | |

| Size | 859.48 KB |

| Downloads |

Text Preview

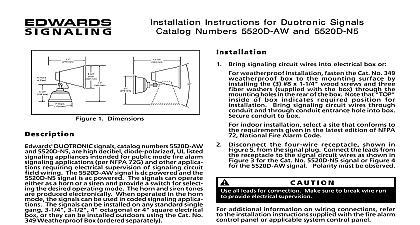

Installation Instructions for Duotronic Signals Series 5520 and 5521 1 Dimensions DUOTRONIC signals are heavy duty high deci UL listed signaling appliances intended for use in gen signaling and alarm applications The 5520 series of can operate either as a horn or a siren and provide switch for selecting the desired operating mode The signal operates as a horn only The horn and si tones are produced electronically Signals operating the horn mode can be used in coded signaling applica 5520 series of signals can be installed on any standard gang 3 1 4 83 mm 3 1 2 89 mm or 4 102 octagonal or 4 102 mm square electrical box or can be installed outdoors using the Cat No 349 Box ordered separately Also the Cat Nos and 5520 AQ signals can be direct wall mounted Cat No 5521 S1 signal can be installed indoors or and is supplied with a Cat No 349 R Weather Box The box must be used when installing the Cat 5521 S1 signal indoors as well as outdoors because it a dropping resistor that is required for operation the signal Specifications Voltage Current A 60 Hz DC 60 Hz DC 60 Hz DC 60 Hz DC a separately mounted Cat No 598Y supplied with signal to convert AC line voltage to 24V AC Specifications See Figure 1 7 1 2 Pounds 3.4 kg in accordance with the latest edition of the Na Electrical Code and or lother applicable codes and Catalog Series 5520 install as follows beginning the installation of the signal that the power source for the signal is Loosen the screw at the bottom of the signal housing remove the mounting plate from the signal Figure prevent damage to the signal always ensure that is off before operating the horn siren switch Select the desired operating mode by sliding the handle the horn siren switch located in the rear of the housing to the applicable selection For Cat No 5520 R5 signal proceed to step 3 all other 5520 Series models proceed to step 4 Mount the Cat No 598Y transformer on an electrical Connect 240V AC power source wires to wire from primary side of transformer using wire nuts supplied Figure 4 Connect wires to be run to to 24V terminals on secondary side of Figure 4 wires from power source or for Cat No 5520 signal install 24V power source wires from Cat 598Y transformer Install signal mounting plate one of the following procedures TOP on mounting plate and on inside of Cat 349 Weatherproof Box indicates required for installation Direct wall mounting Cat Nos 5520 AS and 5520 only power source wires through hole in wall through center hole in mounting plate mounting plate to wall by installing the 8 x 1 1 4 32 mm wood screws supplied the signal through the appropriate holes in plate as shown in Figure 3 CT 203 699 3300 FAX 203 699 3365 CUST SERV 203 699 3078 TECH SERV P 047550 0437 ISSUE 2 2002 Mounting to electrical box wires installed in step 4 through center hole mounting plate appropriate holes in mounting plate with screw holes in electrical box Fasten to single gang box using the two 6 32 x 5 16 mm screws supplied with the signal or to octagon or square box using screws with the box Weatherproof installation the Cat No 349 Weatherproof Box to the surface by installing the three x 1 1 4 32 mm wood screws and three fiber supplied with the box through the holes in the rear of the box wires installed in step 4 through 3 4 19 NPT conduit and through conduit entrance into box Secure conduit to box appropriate holes in mounting plate with screw holes in bosses of box and fasten to box using the four 8 32 x 7 16 11 mm screws supplied with the box Connect wires from power source or transformer to terminals of the plug receptacle on the mounting as shown in Figure 3 Hook signal on mounting plate by engaging hanger plate into slot in top of signal housing Figure 3 signal flush to mounting plate to mate plug in of signal housing with plug receptacle on plate Tighten screw loosened in step 1 to signal to plate Cat No 5521 S1 install as follows Loosen the screw at the bottom of the signal housing remove the mounting plate from the signal Figure Fasten the Cat No 349 R Weatherproof Box to the surface by installing the three 8 x 1 1 4 mm wood screws and three fiber washers supplied the box through the mounting holes in the rear the box Bring 250V DC power source wires through 3 4 19 NPT conduit and through conduit entrance into box Secure conduit to box Place resistor bracket assembly P 039964 0424 in box resistor facing rear of box as shown in Figure 5 the 250V power source wires to the terminals the assembly Figure 4 Bring the two wire leads from the resistor bracket through the center hole in the mounting Align holes in bracket with mounting screw in lower bosses of box when upper conduit hole is used Figure 5 When bottom conduit hole is used bracket must be aligned with holes in upper bosses in box Align appropriate holes in mounting plate with screw holes in bosses of box and fasten and resistor bracket assembly to box using the 8 32 x 7 16 11 mm machine screws supplied box Connect wire leads from resistor bracket assembly to terminals of the plug receptacle on the mounting Figure 3 Hook signal on mounting plate by engaging hanger plate into slot in top of signal housing Press signal to mounting plate to mate plug in rear of signal with plug receptacle on mounting plate screw loosened in step 1 to secure signal to Speaker Direction adjust the speaker direction loosen the nut shown in 2 Rotate the speaker to the desired position and the nut The speaker position can be adjusted a 90 range vertically and 180 range horizontally Test power to the signal and verify that it sounds For with horn siren mode selection verify that selected of signal is sounding and Subsequent Testing the signal annually for accumulation of dirt if necessary the signal semi annually or at the intervals required applicable regulations and codes 2 Mounting Plate Removal and Directional Adjustment P 047550 0437 ISSUE 2 3 Mounting Plate Details 4 Wiring Installation 5 Resistor Bracket Assembly Installation P 047550 0437 ISSUE 2