Edwards 869dstr-g1

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | edwards-869dstr-g1-0875923164.pdf |

|---|---|

| Type | |

| Size | 693.29 KB |

| Downloads |

Text Preview

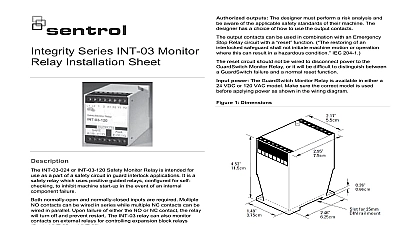

Diode Polarized Electronic Horn Installation Sheet Ground in accordance with national and local electrical A green ground screw is provided with both the and outdoor surface boxes Connect signaling circuit field wires to terminals on assembly Figure 2 4 on page 2 Mount the horn strobe assembly on the mounting plate 1 on page 2 The inside of the top of the grille has hinges that pass cutouts and engage with tabs on the plate With the bottom of the grille lifted out place the grille over the mounting plate so the hinges of the grille are in the mounting Properly seat the grille by pressing the bottom in Fasten the bottom of the grille to the mounting plate installing the captive combination drive screw Apply power and activate the horn strobe unit to verify that is operating properly the volume and tone horn has a jumper for selecting a high or low volume level The default is high volume To set the output to volume remove the output jumper from the circuit board the rear of the unit See Figure 4 on page 3 horn has a jumper for selecting either a temporal or steady The default is temporal tone To set the output to steady remove the tone jumper from the circuit board on the rear the unit Save the jumper by sliding it onto a single pin horn strobes are UL and cUL Listed high quality diode signals intended for use in general signaling The strobes flash at 1 fps across their full voltage range is recommended that these products be installed in with the requirements in the latest edition of and local electrical codes 1 Models Gray Flush or Panel Mount Indoor lens color C clear R red G green B blue or A amber To reduce the risk of shock always disconnect all before handling the unit To reduce the risk of shock do not tamper with device when the signal circuit is energized Disconnect all and wait 5 minutes for stored energy to dissipate before Select mounting method as detailed in Figure 1 on page 2 install the electrical box not supplied using suitable For outdoor applications install the weatherproof box separately using four 10 x 1 1 4 32 mm and cap lugs provided in the enclosed parts Be sure hook flange is facing outward as shown in 1 on page 2 The designation on boxes denotes orientation of after installation Attach mounting plate using two 8 32 screws provided the surface box ordered separately or four 8 32 provided with the weatherproof box ordered The flush box uses two 8 32 screws not Bring signaling circuit field wiring into electrical box 2011 UTC Fire Security All rights reserved 3 3100285 REV 2.0 ISS 22JUL11 1 Mounting diagram 2 Typical one circuit wiring diagram 3 Typical two circuit wiring diagram is shown in the active state From voltage source To next device or end of line resistor horn and strobe must be connected to a signal circuit having a non coded voltage output Electrical supervision requires wire run to be broken at each Do not loop signaling circuit field wires around terminals is shown in the active state From voltage source To next device or end of line resistor strobe must be connected to signal circuits having a constant voltage output The horn must be connected to a voltage when it is set to sound a temporal tone it may be to either a pulsed or continuous voltage when set to sound steady tone Electrical supervision requires wire run to be broken at each Do not loop signaling circuit field wires around terminals 3 3100285 REV 2.0 ISS 22JUL11 Regulatory information A Division of UTC Fire Security Corporation Inc Town Center Parkway Bradenton FL USA first two digits of the date code located on product identification label are the year of DC outdoor UL 464 and UL 1638 equipment has been tested and found to with the limits for a Class A digital device to Part 15 of the FCC rules and of rating American compliance information contact information see www edwardssignaling com 4 Jumper setup and terminal block output tone output continuous Do not change the factory applied finishes unit is shipped from the factory as an assembled unit it no user serviceable parts and should not be a visual inspection and an operational test twice a or as directed by the local authority having jurisdiction VDC voltage operating current 320 mA at 24 VDC operating current See Table 2 below Table 3 below output temperature to 120 0 to 49 outdoor to 150 to 66 humidity noncondensing noncondensing 2 Maximum horn operating current 1 VDC Horn and strobe currents are additive when connected in parallel Volume mA Volume mA 3 Anechoic chamber average peak sound output dBA 1 VDC High Sound level output at 10 ft 3.05m 3100285 REV 2.0 ISS 22JUL11 3