Edwards Data Sheet 250CO-Carbon Monoxide Detector Iss 4

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | edwards-data-sheet-250co-carbon-monoxide-detector-iss-4-6073189425.pdf |

|---|---|

| Type | |

| Size | 1.39 MB |

| Downloads |

Text Preview

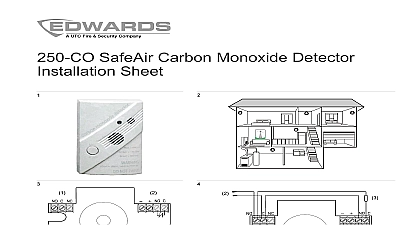

Edwards Signaling Catalog u Conventional Initiating 12 24VDC Monoxide with SafeTestTM SafeAirTM 250 CO carbon monoxide CO detector is an accu and reliable means of alerting building occupants of potentially levels of CO in the protected area The internal electro sensor communicates with a sophisticated on board that accurately tracks CO levels over time commercial grade detection technology results in quick reliable sensing fast reset time and superior false alarm Its small size allows the 250 CO to blend inconspicu with any decor and its smooth contoured design is compat with both residential and commercial environments by normal indoor temperature variations the 250 CO self adjusts for environmental changes and operates reli under a wide variety of conditions It also monitors its own and automatically compensates for sensitivity drift the course of its service life 250 CO features the SafeTest functional test feature which testing with real CO gas SafeTest meets the functional requirement in NFPA 720 2009 2012 editions all CO detectors the 250 CO has a limited service life When approaches this point the 250 CO six year end of life timer triggers a warning locally at the control panel and at a central monitoring station indicating that the device be serviced integrated temporal 4 sounder horn provides local signaling capa for the 250 CO and it easily interfaces with any listed intrusion or alarm system by means of its 150mA output relay Its low current results in little additional demand on the system power supply 250 CO fully complies with the latest UL 2075 requirements allows for installation in a wide range of both residential and settings Features SafeTest enables a full functional test with spray of real CO Electro chemical sensing technology Transmits sensor end of life to the control panel and central if the system is monitored Fully listed to the latest UL 2075 CO standard for residential or occupancies Built in trouble power supervision relay Six year sensor Self diagnostics keep the device operating optimally through its service life 12 or 24VDC operation and 150mA relay contact configurable normally open or normally closed operation Large SEMS terminals ease wiring installation 14 to 22 AWG One touch TEST HUSH button simplifies local operation Integrated 85 dBa temporal 4 sounder for local notification On board LED provides local alarm and trouble indication Inconspicuous footprint and attractively contoured design Adapter plate makes replacing 240 COe CO detector simple 1 of 4 D A T A S H E E T S85001 0618 to be used for installation purposes Issue 4 functional test This test facilitates the use of CO test to verify the correct operation of the detector Functional is mandatory per NFPA 70 as of January 2012 SafeTest is activated by pressing and holding down the test hush per the installation instructions While in SafeTest mode UL approved CO testing spray at the sensor port will in the activation of the alarm relay and the sounder and red to activate in a temporal four pattern Pressing and holding test hush will exit SafeTest mode 85 dB temporal four sounder alarm The 85 dB sounder provides a distinctive alarm notification that easy to differentiate from smoke alarm notification devices The beeps four times rests five seconds and then repeats the button Use the test hush button to test the alarm and an activated alarm Pushing the test hush button silences integral sounder for five minutes The red alarm light stays on if CO is still present after five minutes the detector once again in the temporal four pattern The hush feature does not at CO levels above 350 ppm parts per million of sensor life indicator The detector uses both a flash green LED and intermittent sounder chirps to indicate that the needs replacing To silence the detector push the test button The detector also begins signaling a trouble when the sensor is approaching end of life When connected to a Listed panel the trouble relay can report a trouble condition locally the panel and optionally at the central station if the system is trouble relay The trouble relay opens to indicate a condition upon lost power CO sensor cell trouble or cell 250 CO Carbon Monoxide Detector is a four wire device to use a Class 2 output from a control panel or auxiliary supply Listed to UL 985 or 864 standards wiring must conform to the NFPA 70 National Electric Code UL NFPA 720 an applicable codes Use 14 to 22 AWG wire Connect the CO detector only to a zone dedicat exclusively for CO detection and that is monitored 24 hours day Do not connect to an initiating circuit with fire or security Failure to properly install test and maintain a CO may cause it to fail potentially resulting in loss of life 250 CO 240 COe adapter plate the 250 COPLT 5PKG adaptor plate when replacing a 240 with a 250 CO to cover the footprint of the 240 COe For use the plate to cover any paint discoloration left behind the 240 COe SafeAir 250 CO Carbon Monoxide Detector is intended for indoor dwelling unit applications in both residential and occupancies including single multiple family residential hotel rooms dorm rooms and other areas approved the authority having jurisdiction AHJ The 250 CO detector connect to either UL 985 Household Fire Warning or UL 864 Fire control panels It is not intended for use in indus applications such as gasoline refineries or parking garages require different listings The 250 CO detector has an optional mounting plate for the 240COe CO detector To purchase plate order P N 250 COPLT 5PKG a suitable location is critical to the operation of CO Install the 250 CO in accordance with NFPA 720 Stan for the Installation of Carbon Monoxide CO Detection and Equipment Place wall mounted detectors at least 5 ft m up from the floor For ceiling mounted applications place detector at least 1 ft 0.3 m from any wall hotel rooms and dorm rooms CO detector locations 9 Within 10 ft 3 m of all sleeping areas including areas such 9 In a suitable environment areas with a temperature range of to 104 0 to 40 and with a relative humidity range of 0 90 noncondensing 9 In residential dwellings locate detectors in every bedroom 10 ft 3 m of sleeping areas and on each level At a place one detector outside the sleeping areas Recommended locations for CO detectors check with your local building codes and Authority Having Jurisdiction specific CO location requirements in your area CO detector locations in commercial occupancies 9 On every habitable level of the building based on an engineer evaluation considering potential sources and migration of monoxide 9 In any area required by local building codes legislation or Having Jurisdiction 9 On a firm permanent surface not install the CO detector 8 Within 10 ft 3 m of a fuel burning appliance 8 Near air conditioners heating registers and any other ventilation 8 Where furniture or draperies may obstruct the airflow 8 In a recessed area that may interfere with CO gas entering the detector 2 of 4 D A T A S H E E T S85001 0618 to be used for installation purposes Issue 4 Single device single zone NO pro by the safety Multiple devices single zone NO NC NO NC Multiple devices separate alarm trouble zone NC NO C NC NO C device by the life safety system pro by the safety pro by the safety 3 of 4 D A T A S H E E T S85001 0618 to be used for installation purposes Issue 4 alarm since 1872 800 336 4206 860 284 3083 Edwards 519 376 2430 519 376 7258 Asia 65 6391 9300 65 6391 9306 91 80 4344 2000 91 80 4344 2050 61 3 9239 1200 61 3 9239 1299 32 2 725 11 20 32 2 721 86 13 America 305 593