Edwards SuperDuct Conventional Two Wire Duct Smoke Detector

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | edwards-superduct-conventional-two-wire-duct-smoke-detector-3251946807.pdf |

|---|---|

| Type | |

| Size | 893.71 KB |

| Downloads |

Text Preview

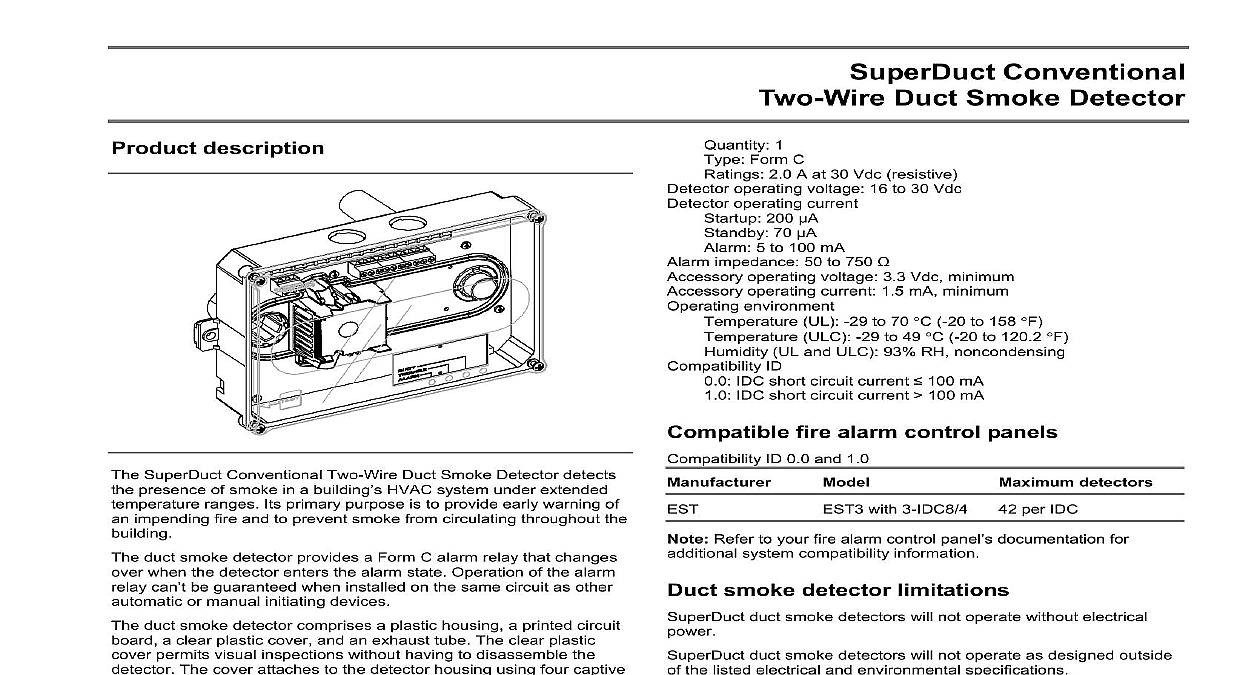

description SuperDuct Conventional Two Wire Duct Smoke Detector detects presence of smoke in a building HVAC system under extended ranges Its primary purpose is to provide early warning of impending fire and to prevent smoke from circulating throughout the duct smoke detector provides a Form C alarm relay that changes when the detector enters the alarm state Operation of the alarm can be guaranteed when installed on the same circuit as other or manual initiating devices duct smoke detector comprises a plastic housing a printed circuit a clear plastic cover and an exhaust tube The clear plastic permits visual inspections without having to disassemble the The cover attaches to the detector housing using four captive and forms an airtight chamber around the sensing electronics sampling tube is required to introduce air into the detector The tube is ordered separately and varies in length depending on width of the HVAC duct document applies to the following duct smoke detector models and SD 2W SuperDuct duct smoke detectors are not intended as for open area protection documents information regarding duct smoke detector installation testing and not included in this installation sheet refer to Technical P N 3100737 8.70 x 5.45 x 1.90 inches size 14 to 22 AWG detection method Photoelectric light scattering principle velocity rating 100 to 4,000 ft min pressure differential 0.005 to 1.00 inches of water 0.79 to 2.46 ft obscuration time 1 second max up time 30 seconds max test response time 5 seconds indicators Alarm red Trouble yellow Dirty yellow alarm relay and power limited Conventional Duct Smoke Detector 1 Form C 2.0 A at 30 Vdc resistive operating voltage 16 to 30 Vdc operating current 200 70 5 to 100 mA impedance 50 to 750 operating voltage 3.3 Vdc minimum operating current 1.5 mA minimum environment UL 29 to 70 20 to 158 ULC 29 to 49 20 to 120.2 UL and ULC 93 RH noncondensing ID IDC short circuit current 100 mA IDC short circuit current 100 mA fire alarm control panels ID 0.0 and 1.0 detectors with 3 IDC8 4 per IDC Refer to your fire alarm control panel documentation for system compatibility information smoke detector limitations duct smoke detectors will not operate without electrical duct smoke detectors will not operate as designed outside the listed electrical and environmental specifications duct smoke detectors will not sense smoke unless the system is operating and the sensor cover is properly duct smoke detectors may not operate as designed unless in accordance with these instructions and all applicable and local codes as determined by the local authority having duct smoke detectors may not be installed on circuits that alarm verification guidelines the duct smoke detector on a flat section of HVAC duct between and ten duct widths from any bends or obstructions supply side detectors at a point downstream from the supply fan after the air filter return side detectors at a point before the return air stream is by outside air tubes must extend at least two thirds across the width of the Sampling tubes longer than 36 inches must be supported at both ends instructions read these instructions thoroughly before installing In addition this document important information can be found in Technical P N 3100737 Sheet Conventional Two Wire Duct Smoke Detector P N 3100689 REV 1.0 4 1 Verify the duct air velocity a small hole at the point where the duct smoke detector is being Using the SD VTK Air Velocity Test Kit and a suitable air meter verify that the air velocity in the HVAC duct falls within specified operating range of the detector and note which direction air flows the air velocity does not fall within the specified range relocate the and seal the hole in the HVAC duct In order to verify airflow direction and velocity air must be through the HVAC system 2 Drill the mounting holes the drill template to the HVAC duct Drill or punch the holes where indicated Remove any rough edges from the 3 Assemble the detector the duct smoke detector as shown in Figure 1 Rotate the air tube so the inlet holes face the direction of airflow In some applications it may be desirable to install the sampling through the front of the detector For details refer to Technical P N 3100737 tube tube tube For duct widths greater than 36 inches use a sampling tube that longer than the width of the duct see Figure 3 4 Mount the detector the duct smoke detector on the HVAC duct as shown in Figure Secure the detector using the two sheet metal screws provided in hardware kit duct sheet metal screw 2X 2 Detector installation diagram the sampling tube is longer than the width of the duct drill a 3 4 inch on the opposite side of the duct Extend the sampling tube the hole as shown in Figure 3 and seal the opening around the with an approved sealant tube tube separately 1 Detector assembly diagram tubes must extend at least two third across the width of the and must be supported at the far end if longer than 36 inches tubes are available in the lengths listed below sampling tube sampling tube sampling tube sampling tube sampling tube sampling tube sampling tube sampling tube 36 in 3 Installation with sampling tubes longer than the width of the 3100689 REV 1.0 4 Sheet Conventional Two Wire Duct Smoke Detector 5 Verify the air pressure differential the duct smoke detector and connect a suitable air pressure meter to the sampling tube and exhaust tube openings as in Figure 4 Verify that the air pressure differential measured the two openings falls within the specified operating range of detector To measure air pressure differential you must have a suitable pressure differential meter supplied by the installer and an SD Air Velocity Test kit the short circuit current specification of the control panel device circuit IDC then wire the duct smoke detector as in Figure 5 or Figure 6 duct Wiring the incorrect terminals to the initiating device circuit cause equipment damage tube completing the installation test the duct smoke detector to ensure it is operating correctly before leaving the site For details refer to Bulletin P N 3100737 tube pressure 4 Air pressure differential measurement Sheet Conventional Two Wire Duct Smoke Detector 3100689 REV 1.0 4 or SD TRM 2 or SD TRM 2 End of line resistor is required the last detector only The value determined by the fire alarm panel s initiating device No more than one remote test can be connected at the time Wiring is unsupervised wire resistance is 10 per wire Only the first detector to go into operates its alarm relay of the alarm relay can t guaranteed if a manual initiating on the same circuit is End of line resistor is required the last detector only The value determined by the fire alarm panel s initiating device No more than one remote test can be connected at the time Wiring is unsupervised wire resistance is 10 per wire Only the first detector to go into operates its alarm relay