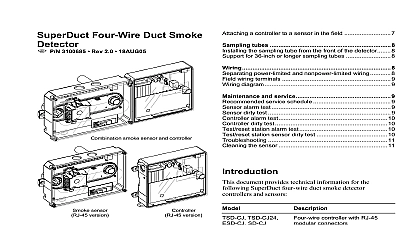

Edwards SuperDuct Conventional Two-Wire Duct Smoke Detector Technical Bulletin

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | edwards-superduct-conventional-two-wire-duct-smoke-detector-technical-bulletin-4695327801.pdf |

|---|---|

| Type | |

| Size | 1.11 MB |

| Downloads |

Text Preview

SuperDuct Conventional Two Wire Duct Detector P N 3100737 Rev 1.0 06SEP05 document provides technical information for the Conventional Two Wire Duct Smoke Detector to simply as duct smoke detector for the remainder of document document applies to the following duct smoke detector ESD 2W and SD 2W documents addition to this document important information regarding proper installation and maintenance of duct smoke is provided in the following standards NFPA 70 National Electrical Code NFPA 72 National Fire Alarm Code NFPA 90A Installation of Air Conditioning and Systems UL 268A Smoke Detectors for Duct Applications ULC 529 Smoke Detectors for Fire Alarm Systems NEMA Guide for Proper Use of Smoke Detectors in Duct smoke detector limitations duct smoke detectors will not operate without power duct smoke detectors will not operate as designed of the listed electrical and environmental duct smoke detectors will not sense smoke unless ventilation system is operating and the sensor cover is installed duct smoke detectors may not operate as designed installed in accordance with these instructions and all national and local codes as determined by the local having jurisdiction description duct smoke detector is used to detect smoke in the premises HVAC system under extended ranges It can be installed in self contained rooftop HVAC systems where the HVAC compressor condensing unit heating coils etc enclosed in a single package to protect them from adverse 1 documents 1 smoke detector limitations 1 description 1 1 2 2 3 4 and indicators 4 state 4 state 4 state 4 4 guidelines 4 sequence 5 the sampling tube from the front of the detector 5 sampling tubes greater than 36 inches long 5 and service 6 service schedule 6 the duct smoke detector 6 6 the duct smoke detector 6 Bulletin Conventional Two Wire Duct Smoke Detector conditions Hinged or removable service panels provide access to the equipment duct smoke detector primary purpose is to provide early of an impending fire and shut down the HVAC unit in to prevent smoke from circulating throughout the It is typically used to detect smoke in the supply side the HVAC system but can provide supervision of the return as well see Figure 1 and is directed back into the ventilation system through exhaust tube The difference in air pressure between the tubes pulls the sampled air through the sensing chamber a sufficient amount of smoke is detected in the sensing the duct smoke detector notifies the fire alarm panel Excess temperature differentials between the air and the sampled air can produce unwanted inside the detector which may cause the detector function improperly Precautions should be taken to limit temperature range and the amount of condensation to the detector is exposed HVAC unit smoke smoke air air duct smoke detector see Figure 2 comprises a plastic a printed circuit board a clear plastic cover an tube and a sampling tube The exhaust tube and tube are attached during installation The sampling varies in length depending on the size of the HVAC duct is ordered separately clear plastic cover permits visual inspections without to disassemble the detector The cover attaches to the housing using four captive screws and forms an chamber around the sensing electronics 1 Duct smoke detector application diagram SuperDuct duct smoke detectors are not intended substitutes for open area protection Install supply side detectors at a point downstream from supply fan and air filters and return side detectors at a before the return air is diluted by outside air installations where the duct smoke detector controls and are hidden from view a remote test station or an indicator can be connected to the detector to provide functions duct smoke detector uses differential sensing to prevent environmental changes from triggering false alarms A change in environmental conditions such as smoke from fire causes the detector to automatically signal an alarm but dust and debris accumulated over time does not is introduced to the duct smoke detector sensing through a sampling tube that extends into the HVAC duct smoke detector incorporates the following features Environmental compensation with differential sensing for stable and drift free sensitivity Magnet activated test switch mounted photoelectric detector with onboard Cover tamper switch for added security tube can be installed with or without the cover place and can be rotated in 45 degree increments to proper alignment with duct airflow Alarm Trouble and Dirty status LEDs Extended temperature and air velocity ranges One Form C auxiliary alarm relay for controlling ancillary e g HVAC controls Bulletin Conventional Two Wire Duct Smoke Detector A tube separately nuts by installer A 2 Duct smoke detector exploded view 8.70 x 5.45 x 1.90 inches size 14 to 22 AWG detection method Photoelectric light scattering velocity rating 100 to 4,000 ft min pressure differential 0.005 to 1.00 inches of water 0.79 to 2.46 ft obscuration time 1 second max up time 30 seconds max test response time 5 seconds indicators Alarm red Trouble yellow Dirty yellow alarm relay and power limited 1 Form C 2.0 A at 30 Vdc resistive operating voltage 16 to 30 Vdc operating current 200 70 5 to 100 mA impedance 50 to 750 operating voltage 3.3 Vdc minimum operating current 1.5 mA minimum environment UL 29 to 70 20 to 158 tube gasket conduit couplings by installer housing electronics support cover ULC 29 to 49 20 to 120.2 UL and ULC 93 RH noncondensing ID IDC short circuit current 100 mA IDC short circuit current 100 mA Refer to the fire alarm control panel documentation system compatibility details accessories that you can use with the duct smoke detector listed below