VESDA ECO™ Ex Gas Detector

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | vesda-eco-ex-gas-detector-8043975612.pdf |

|---|---|

| Type | |

| Size | 1.08 MB |

| Downloads |

Text Preview

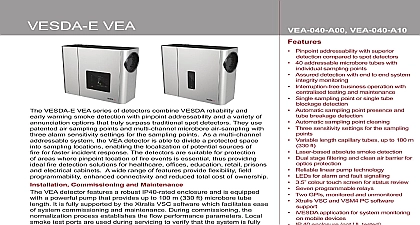

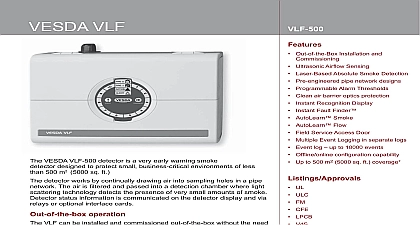

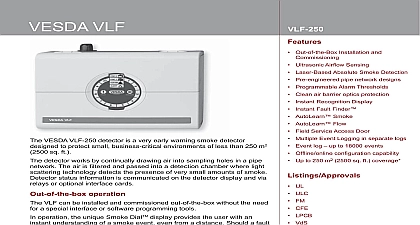

VESDA ECO Ex Gas Detector Detection for Use with Aspirating Detection the manufacturer of the market leading VESDA smoke detection ASD technology has the industries first multi hole aspirated gas used with the compatible range of ASD VESDA ECO Ex provides the industries combined aspirated smoke and gas detection ECO Ex provides early warning of toxic and flammable gas hazards to protect and property whilst ensuring business ECO Ex is approved for use within Class Division 2 classified hazardous locations It must used with a similarly approved ASD and installed the Class I Div 2 area include Battery charging rooms Boiler plant rooms Utility service tunnels Refrigerated stores and plant rooms Water treatment and sewerage plants Power generation plants Metal processing plants and more It Works ECO Ex uses an existing or new aspirating pipe network to actively for gas escapes and build ups VESDA ECO Ex gas detector can house up to two gas sensors and detectors can be added easily to the pipe network to monitor more if required Pre calibrated sensor cartridges are easily replaced in the field make converting to different gas sensors or replacing sensors a simple task VESDA ECO Ex detector is configured using Xtralis VSC configuration and can be remotely monitored using Xtralis VSM4 monitoring software VSC and VSM can be used to download data from the on board memory for data analysis and trending of historical data with other building systems including fire alarm control panels HVAC and building management systems provides real time situational for intelligent emergency response ECO Ex by Xtralis provides significant installation and routine cost savings over conventional multi point gas detection solutions reducing the number of detectors required to cover an area and by providing access for routine maintenance Detector for Locations Approved for Class I Div 2 applications Toxic Oxygen or Flammable gas Single or dual gas versions Factory calibrated sensor cartridges Integral alarm status LEDs Integrates with PLCs HVAC BMS FACP Configurable relays 4 20 mA analog outputs RS485 Modbus output On board event logging On board fault diagnostics Integral gas test port Remote reset VESDA ASD ICAM ASD FAAST Electrical safety Conforms to ANSI UL Std 61010 1 Certified to CAN CSA Std C22.2 61010 1 EN 61010 1 EMC FCC 47CFR Part 15B class B 003 EN 50270 Hazardous Location ETL approved to ISA12.12.01 C22.2 No 213 Class I Div 2 Groups ABC D T4 Tamb 131 SIL Rating SIL 2 as per IEC 61508 combustible gas CO2 versions SIL 1 as per IEC 61508 toxic gas and version Consult with Xtralis if the application requires removal of gases ECO Ex Gas Detector ECO Ex Ordering information ECO Ex gas detectors are supplied complete with Outer metal casing surface mounting assembly detector housing sensor cartridge data storage and USB interface cable Detector outputs include relays analogue outputs a serial output Gas Units number structure ECO D B AA Ex AA with the relevant gas type number below Hydrogen H2 0 100 LFL Methane CH4 0 100 LFL Propane C3H8 0 100 LFL Hydrogen H2 0 2000 ppm Gasoline Vapor 0 100 LFL Pentane C5H12 0 100 LFL Alcohols 0 100 LFL Oxygen depletion only O2 0 25 v v Oxygen depletion and enrichment O2 0 25 v v Carbon Monoxide CO 0 500 ppm Hydrogen Sulphide H2S 0 100 ppm Sulphur Dioxide SO2 0 10 ppm Nitrogen Dioxide NO2 0 10 ppm Carbon Dioxide CO2 0 5 v v Gas Unit number structure ECO B AA BB Ex 43 Methane and Hydrogen Sulphide sensor cartridge part number structure ECO SC AA BB Ex SC Sensor Cartridge AA BB are 1st and 2nd gas types see above ECO Ex is designed to press fit on to the air sampling pipe To fit VESDA Ex simply remove a 60 mm section of pipe when using 25 mm OD air pipe work or 4 for BSP pipe Use ECO FT15 adapter when fitting to 6mm based sampling systems ECO Ex provides total flexibility to install one or more detectors anywhere the pipe network to enable monitoring of a specific point zone or total area Detector for Locations Voltage VDC Consumption 24 VDC W max Consumption 60 mA 24 VDC per sensor Gas quantity dependant protective enclosure x 5.3 x 2.9 mm x 135 mm x 74 mm 304 Stainless Steel Detector lb 1 kg detector and enclosure ratings minimum Conditions typically 4 to 122 to 50 gas dependent 4 to 131 20 to 55 4 to 104 20 to 40 10 95 RH non condensing 5 Pipe Size Diameter 25 mm EU Access x PG9 cable glands to suit 0.157 to 4.0 to 8.5 mm outer cable diameter size sq in 1.5 mm2 16 AWG maximum 4 programmable relays 30 VDC 1A 4 20 mA outputs one per gas sensor 2 wire RS 485 Modbus RTU Memory Card SD card 2 GB 8 GB events and Europe 44 1442 242 330 D A CH 49 431 23284 1 The Americas 1 781 740 2223 East 962 6 588 5622 Asia 86 21 5240 0077 Australia and New Zealand 61 3 9936 7000 contents of this document are provided on an is basis No representation or warranty either express or implied is made as to the completeness or reliability of the contents of this document The manufacturer reserves the right to change designs or specifications without obligation without further notice Except as otherwise provided all warranties express or implied including without limitation any implied warranties of and fitness for a particular purpose are expressly excluded the Xtralis logo The Sooner You Know VESDA E VESDA ICAM ECO OSID HeiTel ADPRO IntrusionTrace LoiterTrace ClientTrace XOa XOh iTrace iCommand iRespond iCommission iPIR and FMST are trademarks and or registered trademarks of Xtralis and or its in the United States and or other countries Other brand names mentioned herein are for identification purposes only and may be trademarks their respective holder s Your use of this document does not constitute or create a licence or any other right to use the name and or trademark and label document is subject to copyright owned by Xtralis You agree not to copy communicate to the public adapt distribute transfer sell modify or any contents of this document without the express prior written consent of Xtralis 21716 08