Potter EVD-2 Electronic Vibration Detector with Remote Pickup

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | potter-evd-2-electronic-vibration-detector-with-remote-pickup-0897136425.pdf |

|---|---|

| Type | |

| Size | 1.13 MB |

| Downloads |

Text Preview

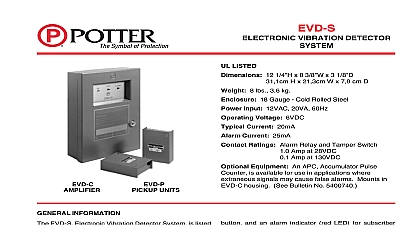

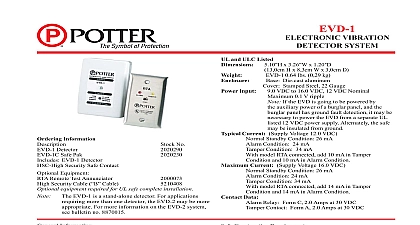

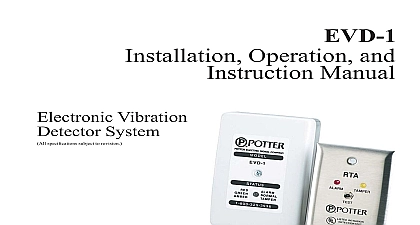

EVD 2 VIBRATION SYSTEM and EVD R x 3.26 W x 1.20 D H x 8,3cm W x 3,0cm D and ULC Listed Input 9.0 VDC to 16.0 VDC 12 VDC Nominal EVD M 0.64 lbs 0,29 kg EVD R 0.62 lbs 0,28 kg Base Die cast aluminum Cover Stamped Steel 22 Gauge 0.1 V ripple If the EVD is going to be powered by the power of a burglar panel and the burglar has ground fault detection it may be necessary power the EVD from a separate UL listed 12 VDC supply Alternately the safe may be insulated ground Current Supply Voltage 12.0 VDC With model RTA connected add 10 mA in Tamper Condition and Standby Condition 34 mA Condition 33 mA Condition 41 mA additional EVD R Remote Pickup adds approx 3 mA mA in Alarm Condition Current Supply Voltage 16.0 VDC With model RTA connected add 14 mA in Tamper Condition and Standby Condition 36 mA Condition 33 mA Condition 43 mA mA in Alarm Condition Data Alarm Relay Form C 2.0 Amps at 30 VDC Contact Form A 2.0 Amps at 30 VDC torches thermic lances drills grinders or cutting discs As soon as the detects a large amplitude alarm source it signals an alarm EVD M controller supports up to 15 EVD R remote pickups or may used as a stand alone unit and fully supervises EVD R wiring Construction Requirements 1 Maximum linear distances from detector to any point on the protected surface the number of detectors for a safe application Construction Linear Distance Detector to Any Point Safes Body Minimum 1 4 Door Minimum 1 2 Safes Minimum 16 gauge steel 3 composite material minimum 1 4 steel over 3 material inches inches to column one in Table 1 for the type of the safe in the In column two find the maximum linear distance from detector to any point on the protected surface This distance is No Information System Of EVD M Controller EVD R Remote Pickup Safe Vault Pak HSC 1 High security safe contact Equipment Remote Test Annunciator Security Cable Cable For one detector applications order 1 EVD M controller equipment is required for UL safe complete installation Information EVD 2 Electronic Vibration Detector System is listed by Laboratories Inc for primary protection of Mercantile Bank safe or vault ATM machines and supplementary protection of units such as file cabinets display cases walls and ceilings The must be used with an appropriate UL listed control unit standard EVD 2 system consists of a model EVD M controller and model EVD R remote pickup Detects all common threats to safes and vaults Sophisticated signal processing provides unprecedented sensitivity false alarms Expandable system allows up to 15 remote pickups Model EVD R Reliable sensitive piezo sensor technology On board high security safe contact interface Integral multi color status LED Built in test circuit on both controller and remote pickups Remote test and annunciator capabilities Supervised microprocessor Independent tamper output On board test point facilitates installation and service Built in accumulator Controller EVD M controller detects short duration large amplitude signals like produced in attacks from explosions hammering or chiseling It also long duration small amplitude signals like those produced in attacks Electric Signal Company St Louis MO Phone 866 956 1211 Canada 888 882 1833 www pottersignal com IN USA 8870015 REV J 1 OF 3 VIBRATION SYSTEM of Detectors for Coverage Single Door Safes of Detectors for Coverage Double Door Safes Linear from to Any Point Protected Surfaces Composite Safes detector range Next refer to column one for steel safes or column two for composite safes in Table 2 Find the range of distances upon the detector range that corresponds to the safe in the application Using the row of this range of distances determine the number of from column three if safe has a single door or from column four if safe has double doors In some single detector applications EVD 2 system may be used to protect multiple safes via a combination of an EVD M and multiple EVD R remote pickups For applications a larger distance than that shown in Table 2 consult Potter technical support for assistance 2 Linear from to Any Point Protected Surfaces Steel Safes The Maximum Linear Distance On A Safe rule of thumb for estimating the maximum linear distance from the detector location to any point on the protected surface is h 62 w 55 d 29 X1 62 55 X1 117 X2 2 x 29 55 X2 113 X 113 J 55 29 J 84 D 113 Linear Distance Safe Construction Minimum 1 4 Steel Minimum 1 2 Steel Safe Construction Minimum 16 Gauge Steel over 3 Composite Material Minimum 1 4 Steel over 3 Composite Material 4 EVD 2 Mounting Detector on Safe Door minimum X1 X2 w d maximum X J Compute X1 h w Compute X2 2d w Find Compute Find h Safe Height Safe Width Safe Depth Maximum Linear Distance rule of thumb is valid for most available safe sizes However if any dimension is very large or very small when compared to the other dimensions the safe may not follow this rule In those cases contact technical support for assistance Table 3 lists some common dimensions and their maximum linear distances when detectors are in recommended locations 3 Safe Exterior Dimensions and Maximum Linear Distances Linear inches ft IN USA 8870015 REV J 2 OF 3 VIBRATION DETECTOR SYSTEM Wall Protection 1 shows the rectangular areas of 100 coverage when detectors installed adjacent to one another The detector spacing is the sensor point distance between adjacent detectors The detector spacing the same as the width of the rectangular area of 100 coverage 4 lists the dimensions of the rectangular areas of 100 coverage continuous surfaces for several materials and sensitivity settings a surface extends around a corner via a solid connection detector extends into that surface but the coverage is reduced to 3 4 the remaining detector range All joints cracks and corners dampen borne vibrations Vibration transfer across these imperfections be tested to ensure complete coverage within the detector range constructions require one detector per panel and must be of the materials listed in Tables 1 and 4 1 Wall Protection Diagram Mounting Detector on Safe Door EVD 2 can be mounted on the safe door single door safes only the detector is mounted on the safe door the maximum linear decreases to 73.5 from the sensor location through the to all points on the safe body UL Complete Safe Installations Install in accordance with Underwriter Laboratories standard UL 681 Install EVD M and EVD R detectors in recommended locations at spacings Install UL listed high security contacts on the exterior of the safe UL listed ordinary use con