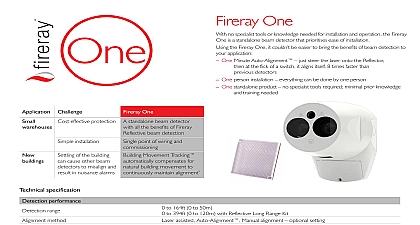

Potter Fireray One manual

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | potter-fireray-one-manual-9246508173.pdf |

|---|---|

| Type | |

| Size | 3.51 MB |

| Downloads |

Text Preview

User Guide de usuario de l per l DE ES FR IT Guide 1 the Box Fireray One Base Fireray One Detector Head Reflector Guide Range Mask guide 2 Information installations should comply with local 0.3m 120m 20m Short Range Mask 50m 1 Reflector NOT position Detector where personnel objects can enter the beam path NOT install the Detector or Reflector in where condensation or icing are to occur unless preventative measures been taken beam as high as possible but with a distance of 0.3m from Detector and to ceiling detectors approved to UL268 refer to for installation guidance In such it is advised that the maximum of Detector and Reflector from the must be 10 of the distance between and ceiling 120m 4 Reflectors correct Reflector selected for the distance Detector and Reflector directly each other not mount Reflector onto reflective 3 Fireray One contains software that the output of the detector and a Fire and Fault status This status output using volt free relays so that it can interfaced to all types of conventional Fire Panel FCP To wire a single Detector an FCP use the following wiring diagram not supplied Fire Resistor Note 1 value is specified by FCP manufacturer U S installations it is typically a short End Of Line component supplied FCP manufacturer installation check operation of Fire and connections to the FCP see page 15 a voltage of 5V to 40V to Reset for at least 2 seconds to clear a latched condition see page 14 for latching mode For system monitoring Do not looped wire under any terminals run to provide monitoring of con Reset 1 4 using more than one Detector on a zone of a conventional FCP it is to choose the correct method wiring Incorrect wiring may result in a isolating subsequent devices on that if it enters a Fault condition and may these subsequent devices signalling a condition back to the FCP the FCP monitors for point detector it is possible to use the following diagram which uses a diode to provide continuity in the event of a Fault state on Detector diode type Schottky 60 Volt Amp must be UL listed for installations NFPA72 Reset In In 1 Out Out 5 Base and drill holes for mounting of Base appropriate hardware not supplied base securely in orientation shown the cable from the Detector head into the on the PCB in the Base the Detector Head on the base Grip of Detector Head and rotate clockwise lock together Base is mounted on solid surface as a structural wall or girder For accessories please see our 6 the and Dip align 7 User Interface window and settings Status door should remain attached to Fireray One however on the rare that it becomes unattached is possible to reattach the tether by the barbed end 8 Status indicators Switch Alignment Off On keys Switch 9 One will align in less than a minute if Alignment is selected In this mode the consumption during alignment will be it will revert to 5mA when alignment is select fast alignment mode ensure the fast setting switch is set to the right hand lower consumption during alignment is then ensure the Fast Alignment switch is set to Off consumption will at 5mA but alignment can take up to minutes RADIATION AVOID EYE EXPOSURE OUTPUT 5mW IIIa LASER 630 680 nm 1 Targeting is the process of using the to get the infra red beam close enough to reflector so that Alignment can begin the targeting setting switch is set to the hand position turn the laser on move the slide switch to left hand position the direction keys to move the laser point to the Reflector the laser cannot be seen for example in very environments or over long distances Prism Targeting mode can be used refer the next page Targeting is complete move to Stage 2 10 2 Alignment moves the infra red beam to the middle of the Reflector select auomatic alignment ensure the setting switch is set to the left hand begin automatic alignment move the slide to the right hand position alignment status LEDs will flash to show The right hand green LED will flash throughout alignment to indicate is occurring The left hand green LED flashes to indicate stage 1 to 4 the process is at If for any reason the alignment fails the LED will flash and the number of it flashes indicates which alignment failed alignment fails ensure that the correct of reflectors are installed that the clearance has been given and that are no reflective surfaces around the or close to the beam path and try alignment again alignment repeatedly fails it is possible to do manual alignment the alignment is successfully complete right hand green LED will flash for 10 Fire and Fault relays will go to normal and the Detector will flash its status green every 10 seconds are now ready to select Alarm Thresholds Latching mode and to test the Detector ensure it is operating and connected to the Control Panel correctly 11 targeting targeting should only be used when laser cannot be seen for instance in high lighting conditions or over very long targeting setting switch is in the right position the slide switch to the left position green and amber LEDs will flash together a few seconds to show the detector has Prism targeting the green LED stays illuminated the is receiving enough light back from Reflector Cover the reflector if the green goes off then the light being received by Detector is coming from the Reflector and can now proceed to the Alignment stage the green LED stays illuminated with the covered then the light received by detector is being reflected by some other in or around the beam path Take care make sure there are no reflective objects 0.5m of the centre of the beam path try Prism Targeting again amber LED will flash every two seconds if Detector is not receiving enough light from Reflector The number of flashes indicate strong a signal it is receiving Using the buttons move the detector in one until the amber flashes increase If the of flashes stays the same then keep in the same direction If the number then reverse direction Once the of flashes starts to increase then keep until either The green LED comes on at which point the reflector as described above The amber flashes start to decrease again at point reverse direction for 2 steps and the same process in the other axis Prism Targeting has been performed on both and the green LED is still not on then that the correct number of reflectors the range has been used that the distance not exceeded the maximum 120m 394ft that the reflector and detector are parallel each other 12 Alignment alignment should only be used when alignment has failed even after it been verified that the correct number of have been installed and the correct around the beam pa