Cerberus Pyrotronics ASD-3 6 12 AnaLASER Detectors 1160

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | cerberus-pyrotronics-asd-3-6-12-analaser-detectors-1160-4516809723.pdf |

|---|---|

| Type | |

| Size | 734.86 KB |

| Downloads |

Text Preview

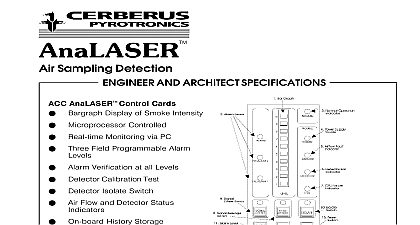

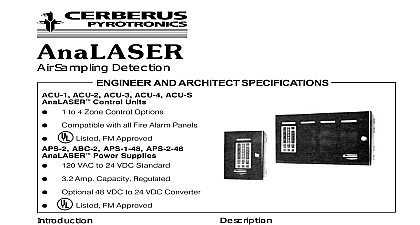

AnaLASER Sampling Detection ENGINEER AND ARCHITECT SPECIFICATIONS ASD 6 ASD 12 AnaLASERTM Detectors Air Sampling Aspiration Smoke Detection Highly Sensitive Detection Times More Spot Type Detectors Laser Light Scattering Technology Applicable to High Air Flow Environments Minimal Maintenance Required Engineered Air Sampling Pipe Network Meets NFPA 72 Standard for Smoke Detectors FM Approved ASD 3 ASD 6 Canada AnaLASERTM detection system is a high sensitivity air system Through the laser based light source fire be detected in its incipient stage Smoke particles are by a fan into an air sampling pipe network to the de This allows detection over a large area in confined or from air return ducts The AnaLASERTM system is Approved and meets NFPA 72 requirements for smoke Applications AnaLASERTM detection system can be used in many where conventional spot type smoke detec are used but are stretched beyond their reasonable The Ana LASERTM system can be used in envi with high volume air movements such as clean or with unpredictable airflow patterns such as atri and hangars It can provide high sensitivity detection a large area Applications which require the detector to obscure as in prisons and museums are also well by the AnaLASERTM system The following list in some of the many applications for the AnaLASERTM system hangars anechoic chambers art galleries atriums rooms cable tunnels cathedrals clean rooms com rooms concert halls container vessels cruise ships equipment racks escalators historical build hospitals hotels laboratories libraries machine motels museums nuclear reactors office buildings accelerators passenger rail prisons radio transmitters recording studios satellite facilities schools sports complexes stadi switchboards telephone exchanges theaters under railway stations warehouses AnaLASERTM system consists of four components Air Sampling Network AnaLASERTM Detector Assembly AnaLASERTM Control Unit see Catalog No 1161 AnaLASERTM Power Supply see Catalog No Sampling Network air sampling network is constructed of 1 inch 3 4 inch and 1 2 inch smooth bore pipe which is distributed the protected area A sampling network may only one length of pipe or up to 20 pipes which all to the detector Air sampling holes are strategically along the pipes according to code per NFPA 72 or as required for maximum protection 1161 NUMBER their size and contribute little to the detector sig level Airflow is monitored with a bead type thermistor is cooled by the air passing through the detection and compared to a reference thermistor mounted the chamber Should the airflow vary or stop a com circuit transmits a signal to the control panel intensity of the laser is monitored and controlled with a control circuit that maintains the stability and of the AnaLASERTM detector over its life Compen is provided by changes in laser intensity due to tem aging of components or contaminant buildup circuit also monitors or supervises the operation of criti components in the system laser photo diode and opti assembly Failure or out of tolerance will result in a fail signal being transmitted to the control panel detectors with different sensitivity dynamic ranges available Sensitivity selection depends on the minimum of smoke to be detected plus the ambient level of air It is necessary to conduct an on site test to deter which sensitivity range is appropriate for the protec of given hazard This test should be conducted before installation is commissioned AnaLASERTM Control Unit and Power see Catalog Number 1161 Archii tect and Arch Air Sampling Smoke Detection System shall be Pyrotronics AnaLASERTM The detector shall be in an airtight enclosure with straight through airflow The air shall pass through the detector without ob or filter which requires maintenance and which inhibit the system ability to detect smoke An optional to a 3 4 inch pipe shall be available to return the air back to the area or duct being protected detector shall use a laser as the light source for detect particles of combustion The laser light source life ex shall be a minimum of 10 years or greater and the energy shall remain constant over that period detector output shall be controlled with a closed loop circuit to maintain the accuracy of the detector The source the photo diode and all critical components be supervised within the detector Upon failure or sig variation detector failure shall be transmitted to the Control Panel The detector shall also super the fan and upon failure or significant variation in air the detector shall transmit a fault condition signal to AnaLASERTM Control Panel fan shall be a high efficiency ball bearing electric centrifugal type design for long life and shall a minimum static pressure of greater than 0.05 of water at all sampling points air sampling piping network shall be a closed end sys constructed of 1 inch ends shall be capped within 6 inches of the last sam inch and 1 2 inch pipe The AnaLASER TM air sampling network may be placed in with airflow velocity as high as 20 feet second The protected by a single detector may be as large as square feet each sampling hole may protect up to square feet Location and coverage of each sampling is governed by NFPA 72 requirements for spot type detectors computerized design program allows the in to distribute the piping throughout the hazard with constraints The program balances the sampling by sizing the holes and pipe diameters to insure air intake from each hole with minimum air transport to the detector Consult an authorized Cerberus Py Sales Outlet for assistance with the proper appli of the AnaLASERTM detection system AnaLASERTM Detector Assembly AnaLASERTM detector assembly consists of a fan box an AnaLASERTM detector The fan box is an airtight en which houses a high efficiency 24 volt DC centrifu fan Centrifugal fans are superior to axial fans and the greater suction pressure necessary in an air system The fan draws air from the air sampling through the AnaLASERTM detector The air passes filtration straight through the detection chamber detector patented optical system focuses a 100 mi diameter laser beam across the detector chamber a single photon detection device collects scattered from the individual particles of smoke as they traverse laser beam concentration is determined by counting these dis events over a period of time These individual par produce an analog signal which is transmitted to the panel large particle size discriminator prevents random large present in unfiltered air from generating an alarm Dust particles which manage to defeat the large rejection circuitry only count as a single particle power supply shall provide 24 VDC power sufficient to the entire system and to charge and maintain a lead acid battery backup supply for 24 hours Detector Specifications Voltage Connection Detector Current Detector Environment Humidity lb matte inch bolts Qty 4 VDC 10 inch flexible conduit to 125 F non condensing to 03 per foot to 06 per foot to 12 per foot point The pipe system shall be supported as required local codes The air sampling system shall be engi for a maximum transport time of 120 seconds and equal sensitivity throughout the entire system approval to proceed install or invoice this contract engineering report must be submitted with the following information Flow rate through detector in cfm Maximum calculated air transport time from the distant hole Pipe diameter of each segment Sample hole diameters and location Calculated suction pressure and location of sampling hole External air flow allowance in feet per second Isometric drawing describing the protected area with segments number air sampling holes number length of all pipe segments and distances holes completion of installation the above mentioned de information shall be verified and empirical values re for periodic maintenance to the system Suction shall be mea