Siemens AD2-4W Air Duct Monitoring Housing, Installation Instructions

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | siemens-ad2-4w-air-duct-monitoring-housing-installation-instructions-4359216078.pdf |

|---|---|

| Type | |

| Size | 723.41 KB |

| Downloads |

Text Preview

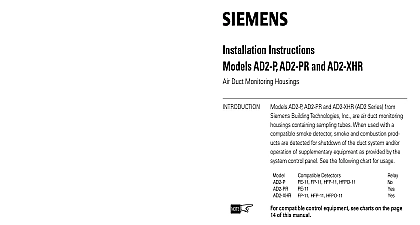

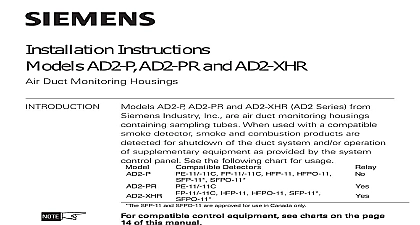

If the fire alarm system is connected to a central station or fire or operates external devices such as fans extin etc connected notify appropriate personnel and the external devices until all tests are completed testing reset the system reconnect the devices and notify personnel that the system is operating again RATINGS FOR PE 11 RATINGS FOR AD2 4W Instructions AD2 4W Duct Monitoring Housing AD2 4W from Siemens Industry Inc is an air duct housing containing sampling tubes When used a PE 11 smoke detector smoke and combustion are detected for shutdown of the duct system and operation of supplementary equipment as provided by the control panel The duct unit supports two sets of C alarm contacts one Form A alarm contact and one C trouble contact The trouble contact supervises the of the input power removal of the detector cover the removal of the smoke detector head Range 0OC 100OF 38OC per UL 268A Range altitude limitations Humidity to 85 RH non condensing non freezing Duct Velocity Range ft min and Exhaust Tube Pressure Differential Range than 0.01 and less than 1.2 inches of water column air duct detectors are designed for detection and of products of combustion in a duct system They are to be used as a substitution for open area protection NOT USE air duct detectors with Alarm Verification ACCESSORIES accessories available for use with AD2 4W are DATA DUCT CONDITIONS Industry Inc Technologies Division Park NJ Building Technologies Ltd Safety Security Products Kenview Boulevard Ontario L6T 5E4 Canada 315 049709 3 315 049709 3 Industry Inc Technologies Division detector has a cover tamper removal switch Care be taken when installing the cover Squarely place the on the unit to aviod possible damage to the switch NOT SLIDE COVER INTO POSITION AD2 4W duct smoke detectors provide early detection smoke and products of combustion present in air moving an HVAC duct supply return or both These devices designed to prevent the recirculation of smoke in areas the air handling system fans and blowers and may be with fire alarm systems that shut down complete air system in the event of smoke detection the correct installation of a duct smoke unit please refer NFPA 72 National Fire Alarm Code NFPA 90A Standard Installation of Air Conditioning and Ventilation Systems NFPA 92A Recommended Practice for Smoke Control detector is not intended for open area protection nor it be used for early warning detection or to replace a fire detection system the Model AD2 4W is operating a sample of air is drawn the duct and passed through the sampling chamber by of the input sampling tube The air sample passes the smoke detector mounted in the duct housing and exhausted back into the duct through the outlet tube AD2 4W supports two sets of Form C alarm one Form A alarm contact and one Form C contact The trouble contact supervises the of the input power removal of the detector and the removal of the smoke detector head AD2 4W contains a green power on LED red alarm and yellow trouble LED which are visible through housing cover trouble LED is activated when either the housing or smoke detector is removed from the unit When the trouble LED is activated the power LED turns off reset test switch is located on the housing cover and used to reset the unit after an alarm and the smoke is cleared When not in alarm the reset test can be used to test that the unit will operate when an alarm condition exists trouble contacts will not operate in the event of a smoke The AD2 4W duct detector will operate from various input sources namely 24VAC 24VDC 115VAC and 230VAC NOT SPRAY GAS FOR MORE THAN SECOND OVER OF TEST GAS MAY RESULT IN DETECTOR CONTAMI 15 to 20 seconds the detector will go into alarm the detector LED and causing the duct unit to operate alarm relays will change state and the related remote accessories if attached will function no test gas is available to conduct functional testing cover and while holding down the cover removal blow smoke from a smoldering cotton wick or punk at the head to cause an alarm The alarm indicator on detector should illuminate within one minute to the PE 11 Installation Instructions P N 315 094198 additional information on testing these detectors detector is equipped with cover removal switch SW1 instantly provides a trouble condition upon removal of clear cover For all testing and inspection with the cover the cover removal switch designated as SW1 on must be manually depressed to simulate normal performance of the air duct detector unit may be affected by dirt or foreign matter on the sampling or detector If the air holes in the input sampling tube restricted the unit cannot receive a proper air and performance is impaired It is recommended the sampling tubes be checked and cleaned periodically detector maintenance program should consist of cleaning of dust from the detector head by using a cleaner For cleaning the PE 11 refer to the Installation Instructions P N 315 094198 cleaning and test program is recommended for 6 month or more frequently if needed depending on the detector environment Consult your local code and requirements for required maintenance schedules no circumstances is the detector portion of the unit be disassembled by anyone other than an authorized Industry Inc Systems Technician For service your nearest authorized Siemens Industry Inc Representative Industry Inc Technologies Division 315 049709 3 315 049709 3 Industry Inc Technologies Division the event of a fire alarm certain equipment may be to be shut down For example shut down may be by interrupting the fan supply source to that piece of equipment when wired as indicated in 6 LED Of PE 11 Smoke Detectors Install cover by loosening the four screws Take off the and set it aside detector with base and insert detector detector clockwise while gently pressing on it the detector drops fully into base rotate the detector clockwise until it stops and in place cover and tighten the four screws Remove the detector counterclockwise until stop is detector out of base qualified service personnel should test these units To proper operation of the detector and control panel the Sensitivity and the Functional tests should be The minimum test schedule may be found in the edition of NFPA 72 for installations in the U S PE 11 detector monitors its smoke sensitivity automati and requires no test equipment A green flash of the LED about every seven seconds indicates that the sensitivity is within its listed limits Testing TG 11 smoke test canister with testing nozzle model purchased separately available from Siemens Inc insert the test gas nozzle into the hole in the plug in the unit cover Press can against cover for about 1 second to release gas into the chamber Test Test THE AIR DUCT HOUSING