Siemens FC901 FC2005 System installation instruction Wiring diagram

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | siemens-fc901-fc2005-system-installation-instruction-wiring-diagram-2841659307.pdf |

|---|---|

| Type | |

| Size | 2.65 MB |

| Downloads |

Text Preview

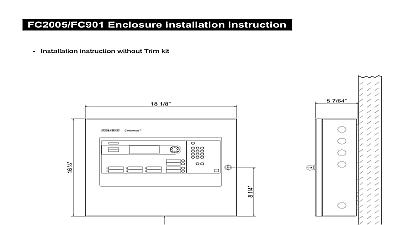

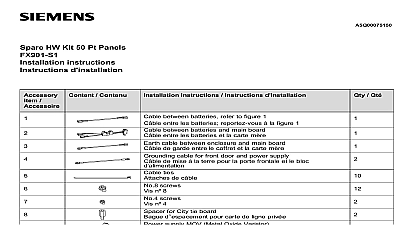

EN installation instruction diagram d du syst de c Infrastructure and separate parts instruction between batteries refer to figure 1 between batteries and main board refer to figure 1 and 2 between City tie board and main board refer to figure 2 cable between enclosure and main board refer to figure and figure 2 cable for front door and power supply refer to 1 bracket left refer to figure 1 bracket right refer to figure 1 ties screws refer to figure 1 screws refer to figure 2 for City tie board refer to figure 2 supply MOV Metal Oxide Varistor refer to figure 2 cell refer to figure 1 supply refer to power supply installation instruction delivered with power supply door hinge axis lock pin refer to Detail A door hinge axis refer to Detail A for NAC refer to Detail C Item 3,6,7,11 S1and S2 are not delivered with the FC901 and FC2005 and should be ordered separately notes Mount the batteries with battery brackets Mount the power supply MOV then mount the power supply to the enclosure Mount the City tie module onto the main board according to the Figure 2 City tie module is optional Connect the cables to the corresponding position marked on the drawing The power supply input cable and output are not included in the FC901 and FC2005 package Mount the Main board assembly onto the Enclosure according to Figure 3 Mount the Lock pin to the Front door axis Both are included in the Enclosure package power supply and City tie PCB assembly installation instruction attention to the battery polarity at 2.1 and 2.2 1 Installation instruction Front view with front door open A Front door hinge and lock pin installation instruction 2 Installation instruction Main board assembly back view tie cable main board and EOL installation instruction 3 Main board assembly installation instruction C NAC EOL installation instruction supply MOV Metal Oxide Varistor installation instruction Bend the MOV connector pin according to the figure below Fix or weld the MOV onto the power input connector Fix the AC input cable and screws on the connector instruction with trim kit instruction without trim kit data temperature 32 120 0 49 humidity Up to 93 90 32 be installed in an indoor dry protected environment Power Supply FP2011 U1 120 VAC 60 Hz or 240 VAC 50 Hz 2.0 A max 26 VDC 6.5 A max current 6.5 A 2 hours max and Regulated Power Supply V lead acid battery set charged voltage 27.8 VDC low battery disconnect voltage 19.2 VDC charge current 0.45 A capacity 12 AH internally to 18 AH with separate FH2072 UA Power Outputs power output Resettable power output limited 0.75 A 19 to 28 VDC 0.1 VAC Application Relays limited programmable relay non programmable relays Trouble Supervisory rating 2 A 30 VDC maximum C contact Appliance Circuits limitedSupervised Draw A A A A A voltage 16 to 32 VDC ripple 0.1 VAC for special application only Class B or one Class A Max Current 2.5 A Line Resistance limited 0.75 A 19 to 28 VDC 0.1 VAC Application Interface Circuit UFP limited wire loop resistance 50 total layer RS485 Addressable Device Circuits 32 VDC limited current 0.07 A RMS wire loop resistance 50 Class B or one Class A circuit 50 addressable devices Tie Circuits Input 26 VDC 18 28 VDC for battery Max 0.4 A Tie Output 1 output voltage 19 28 VDC open circuit condition current 1 mA trip current 400 mA coil plus wire resistance 22.5 line Output 1 output voltage 19 28 VDC open circuit condition output voltage 0 V output voltage 19 28 VDC open circuit condition wire resistance 2 5 K short circuit current 25 mA line Output 2 output voltage 19 28 VDC open circuit condition output voltage 19 28 VDC open circuit wire resistance 2 5 K short circuit current 25 mA Circuits limited for short or open circuit conditions to FCC part 68 RJ31X connection Digital Alarm Communication Receiver list Module To reduce the risk of fire use only No 26 AWG larger telecommunication line cord Only to a loop start telephone circuit and not to a start telephone circuit To verify the integrity of the call forwarding every 24 hours system connection diagram the wiring must be in accordance with local codes and the National Electric Code loop connections and power limited Refer to the user manual A6V10333722 and A6V10336754 Appendix B to get detailed device list for FC901 and FC2005 power and power limited interface circuit limited tie or lease line limited application circuits power limited max current NAC A NAC B 2.5 A limited module compatibility list power limited 2.0 A 30 VDC resistive 0.5 A 30 VAC resistive et pi distinctes d installation entre les batteries reportez vous la figure 1 entre les batteries et la carte m reportez vous la 1 et la figure 2 entre la carte de ligne priv et la carte m reportez la figure 2 de mise la terre entre le coffret et la carte m la figure 1 et la figure 2 de mise la terre pour la porte frontale et le bloc reportez vous la figure 1 de batterie de gauche reportez vous la figure 1 de batterie de droite reportez vous la figure 1 de c n 8 reportez vous la figure 1 n 4 reportez vous la figure 2 d pour carte de ligne priv reportez vous la figure 2 varistance oxyde m de bloc d la figure 2 de batterie reportez vous la figure 1 d reportez vous la fiche d livr avec le bloc d de verrouillage de l charni de la porte frontale D A charni de la porte frontale reportez vous D A de ligne EOL pour NAC reportez vous D C Les articles 3 6 7 11 S1 et S2 ne sont pas livr avec le FC901 ni le FC2005 et doivent command pour l les batteries l des supports batterie la MOV varistance oxyde m du bloc d puis installez le bloc d dans le le module de ligne priv sur la carte m