Siemens FDOOTC441 Multi-Criteria Fire CO Detector, Installation Instructions

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | siemens-fdootc441-multi-criteria-fire-co-detector-installation-instructions-1845036279.pdf |

|---|---|

| Type | |

| Size | 877.57 KB |

| Downloads |

Text Preview

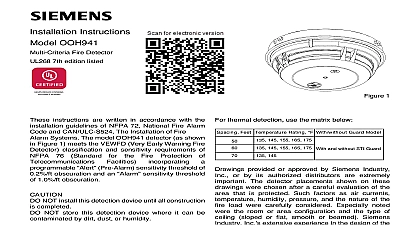

Installation Instructions FDOOTC441 Fire CO Detector 7th edition listed 1 instructions are written in accordance with the guidelines of NFPA 72 National Fire Alarm and CAN ULC S524 The Installation of Fire Systems The model FDOOTC441 detector as in Figure 1 meets the VEWFD Very Early Fire Detector classification and sensitivity of NFPA 76 Standard for the Fire a programmable threshold of 0.2 ft obscuration and an sensitivity threshold of 1.0 ft obscuration NOT install this detection device until all construction completed NOT store this detection device where it can be by dirt dust or humidity PLACEMENT no specific spacings are set for the detectors for a clean air application for multi criteria fire use 30 foot center spacing 900 sq ft from 72 initiating devices chapter if practical as a or starting point for a detector installation layout spacing however is based on ideal conditions ceiling no air movement and no physical less area is protected adequately by each detector This is why it is mandatory to closely the installation drawings In all installations place detector on the ceiling a minimum of 6 inches from side wall or on a wall 12 inches from the ceiling For gas detection applications detector requirements in NFPA 72 for Installation of Monoxide Detection and Warning Equipment For thermal detection use the matrix below Feet Temperature Rating With without Guard Model 145 155 165 175 145 145 155 165 175 and without STI Guard provided or approved by Siemens Industry or by its authorized distributors are extremely The detector placements shown on these were chosen after a careful evaluation of the that is protected Such factors as air currents humidity pressure and the nature of the load were carefully considered Especially noted the room or area configuration and the type of sloped or flat smooth or beamed Siemens Inc extensive experience in the design of the assures the best detector placement by following drawings Sound engineering by personnel must be followed AVOID NUISANCE ALARMS not locate the detectors where excessive smoke exist under normal conditions or in areas prolonged high relative humidity where condensation not locate the detectors next to an oil burner or where exhaust fumes can trigger an alarm Other of false alarm are dust accumulation heavy of steam heavy pipe or cigar smoke and aerosol sprays Industry Inc Infrastructure CURRENTS a detector can sense a fire the products of or smoke must travel from the fire to the This travel is especially influenced by air consider air movement when the system While combustion products tend rise drafts from hallways air diffusers fans etc may or hinder the travel of combustion products to the When positioning a detector at a particular give consideration to windows and doors both and closed to ventilating systems both in and out operation and to other factors influencing air Do not install a detector in the air stream of room air supply diffuser It is better to position a closer to an air return distance that products of combustion or smoke from a fire to the detector is not usually the shortest route Combustion products or smoke usually rise the ceiling then spread out Average ceiling heights of to 10 feet do not abnormally affect detector response ceilings churches warehouses etc do affect detector response and should considered CEILING CONSTRUCTION FACTORS obstructions change the natural movement of air combustion products Depending on the direction of travel joists and beams can slow the movement heated air and smoke while pockets between them contain a reduced level of smoke Take obstructions by girders joists beams air conditioning ducts architectural design consideration when area protection Refer to the Initiating chapter of NFPA 72 for Location and Spacing for specific types of construction e g suspended level sloped and peaked ceilings HUMIDITY PRESSURE AIR temperature range for the FDOOTC441 detector is 0 to 120 49 Use the detector in where the humidity is 15 to 95 RH non condensing and 1 to 99 for short 24 h to 48 h Normal changes of atmospheric do not affect detector sensitivity The air open areas Follow detector spacing and location in NFPA 72 Chapter for High Air Movement and Control of Smoke Spread The detectors can be installed in duct applications between 0 and ft min For duct detector requirements in NFPA 90A Chapter for Ceiling Construction Factors When employ a fixed temperature rating of 165 or less they are intended for a maximum temperature of 100 38 0 4000 ft min INDICATOR OPERATION Model FDOOTC441 contains an LED indicator of flashing either one of three distinct colors yellow or red The microprocessor based monitors the following Smoke in its sensing chamber Smoke sensitivity is within the range indicated on the label sensors and electronics on the results of the monitoring the LED indicator the following Interval supervisory operation sensitivity is within rated is in trouble and needs is not powered or is needed LED can be turned off Please follow the corresponding of the Panel used PROGRAMMING detector must be programmed to respond to an between 001 252 To program the detector address use the Model Device Programming Unit Refer to the DPU P N 315 033260 Record the loop and device number loop address the detector on the detector label and on the base prevent installing the detector in the wrong base optional DPU label printer can be used for this detector provides pre programmed parameter sets can be selected by the panel The FDOOTC441 three different alarm channels the multi criteria and direct in duct UL268A channel with heat detection dedicated heat channel and the CO UL2075 channel They be used simultaneously and configured individually the panel Follow the description and instructions in the operation manual of specific control panel The FDOOTC441 can be set to the FDOOTC441 Application Profiles FDOOTC441 Selectable Temperature Threshold Profiles and FDOOTC441 Alarm Threshold Setting Profiles shown in the below and to the right the detector can have another channel that be configured by the panel to have a low or high warning in the range from 4 to 120 to 49 the detector can be configured by the panel have a CO gas concentration warning in the range of ppm MOUNTING recommended orientation of the detector for wall is shown in Figure 4 To ensure proper of the detector head into the base be sure wires are properly dressed at installation Position all wires flat against the base Take up all slack in the outlet box Route wires away from connector terminals detectors are not to be used with detector guards the combination has been evaluated and found for that purpose UL listed with STI Mechanical Guard Model STI 9604 see www STI for details INSTALL DETECTOR HEAD detector counterclockwise while gently pressing it until the detector seats fully into base rotate the detector clockwise until it stops and locks place Insert optional locking screw Order Model