Siemens II BTD - USP 795,797,and 800 Pharmacy Solution Set Matrix

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | siemens-ii-btd-usp-795797-and-800-pharmacy-solution-set-matrix-5647319820.pdf |

|---|---|

| Type | |

| Size | 796.14 KB |

| Downloads |

Text Preview

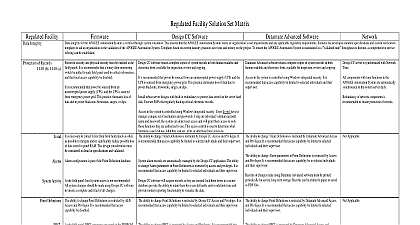

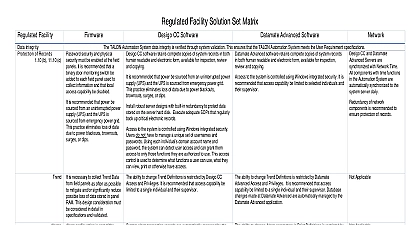

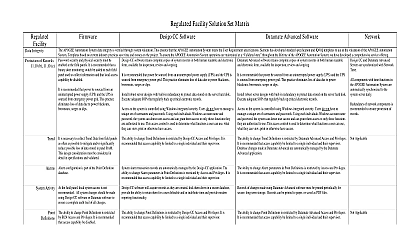

Pharmacy Solution is a bundled offering of products systems technologies programs and services that are specifically designed to help organizations meet the environmental of USP 795 797 and 800 Our solution is built with flexibility in mind allowing us to assemble a customized solution that meets each customer s unique requirements based their current level of compliance document is based on the proposed requirements of Solution Set USP 795 Pharmaceutical Compounding Nonsterile Preparations Proposed Revision March 2018 USP 797 Pharmaceutical Compounding Sterile Preparations Proposed Revision July 2018 USP 800 Hazardous Drugs Handling in Healthcare Settings Proposed Revision February 2016 Coliano Leader Healthcare Industry Inc Technologies Division Spears National Sales Manager Life Sciences Industry Inc Technologies Division Solution Set Matrix 795 Matrix Chapter 795 Requirement Controls activity that may result in airborne powder must be performed in containment ventilated enclosure CVE facilities must be designed controlled to provide a well lit and working environment The room and humidity must be as required to ensure operator Assessment of current environment Room construction Exhaust system Supply air Cooling system Temperature and humidity control Services Solutions Design installation and of room controls for the area to achieve desired and humidity levels RCM II for local monitoring of and humidity Fire alarm system per local codes Backup to EES Essential Electrical power per NFPA 99 System Management RCM II provides local indication of and humidity The Desigo CC workstation serves as primary interface into the building system for real time troubleshooting control of systems alarm management collection of trend data The RENO Remote Notification for Desigo CC allows of alarm status and system information for all points into the system Desigo CC provides for the archiving reporting of data needed to compliance with regulations Intrusion monitoring and alarming Door status Door access restrictions Door interlocks Solutions Compliance services Cabinet testing and certification Calibration Training Automation service offering for compliance Facility information service Environmental reporting and Custom report design and If equipment is integrated can include the room and temperature for the refrigerator and Data archiving and retrieval User training to the compounding area must be Assessment of security and access Secure access into the controlled area Security services Card access CCTV Digital recording based on USP 795 Pharmaceutical Compounding Nonsterile Preparations Proposed Revision March 2018 USP 797 Pharmaceutical Compounding Sterile Preparations Proposed Revision July 2018 USP 800 Hazardous Drugs Handling in Healthcare Settings Proposed Revision February 2016 1 September 2018 2 of 17 Solution Set Matrix Services Solutions Data integration of storage room and freezers into CC for monitoring and alarming System Management Building automation system collects data and alarm statuses from equipment Remote notification of alarm conditions be provided to pharmacy and staff Solutions Facility information services Environmental reporting and Custom report design and creation room environment If equipment is integrated can include refrigerator freezer temperatures Automatic emailing of reports to daily review requirements Data archiving and retrieval User training Desigo CC provides a means of managing processing and business critical data for a of information management and needs including analysis and management Automatic linking of SOPs Training Reporting SOP development Chapter 795 Requirement Storage Areas Nonsterile Preparations may be stored under different conditions before they are used The storage conditions typically apply Controlled room temperature 20 to 25 Refrigerator 2 to 8 Freezer 25 to 10 help ensure CNSP quality personnel must conditions in the storage areas temperature must be checked at daily and the results must be in a temperature log If a recording device is in use must check at least daily that it is that are exposed to temperatures that storage temperature limits shall be Operating Procedures compounding facility must establish and written standard operating procedures designed to ensure the quality of the The SOPs must cover Calibration Environmental monitoring Standards records must be retained for at least three or as required by the state laws and whichever is longer based on USP 795 Pharmaceutical Compounding Nonsterile Preparations Proposed Revision March 2018 USP 797 Pharmaceutical Compounding Sterile Preparations Proposed Revision July 2018 USP 800 Hazardous Drugs Handling in Healthcare Settings Proposed Revision February 2016 1 September 2018 3 of 17 Solution Set Matrix 797 Matrix Chapter 797 Requirement Controls Engineering Controls PECs Compounded Sterile Preparations CSPs be prepared in an ISO Class 5 Class 5 standards are achieved the use of a PEC or an isolator and Cleanroom Areas1 need to be located within a buffer or area with at least ISO Class 7 air An ante area provides access to the area and must meet at least ISO 8 Buffer area for CSPs must be at 0.02 inches water column wc greater adjacent spaces The anteroom which entry into a buffer room must have HEPA filter supplied 20 ACPH Positive pressure of 0.02 inches wc relative all adjacent unclassified spaces ISO Class 8 for CSPs and Barrier Isolators generally include laminar airflow biological safety cabinets and Compounding facilities must be and controlled to provide a well lit comfortable working environment The must be maintained at a temperature of or cooler and a humidity below 60 at times Assessment of current environment Services Solutions Design installation and Air cleanliness Room construction Exhaust system Supply air Cooling system Temperature and humidity control Differential pressure D P control monitoring of enhanced room for the buffer and anteroom to achieve the desired airborne count air changes per hour D P temperature and levels Custom DXR Lab application for PEC DXR Lab application that can interlock PEC fan and provide shutdown flow or pressure is compromised Particle counter integrati