Simplex 4100 4120-Series Relay Module - Installation Instructions

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | simplex-4100-4120-series-relay-module-installation-instructions-5279863140.pdf |

|---|---|

| Type | |

| Size | 1.53 MB |

| Downloads |

Text Preview

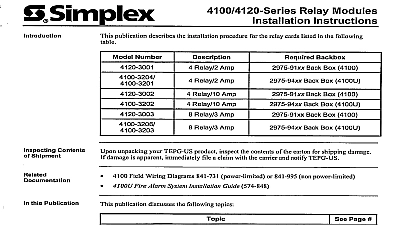

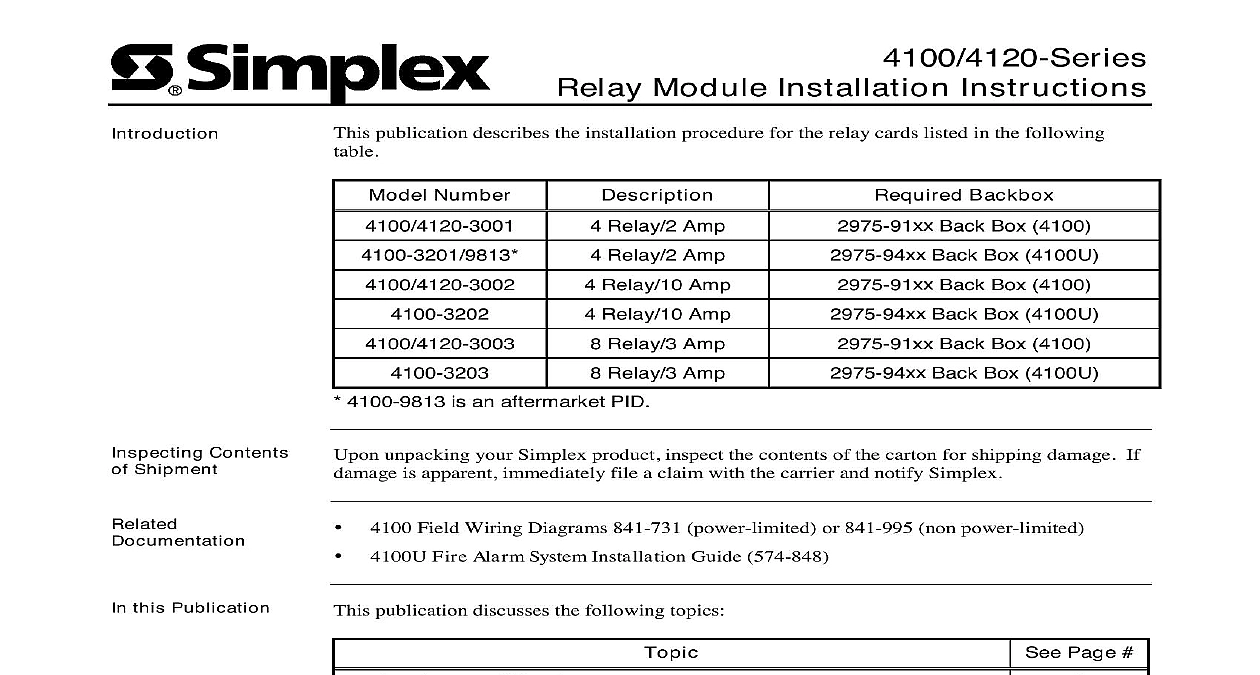

Introduction Module Installation Instructions publication describes the installation procedure for the relay cards listed in the following Number Backbox Relay 2 Amp Back Box 4100 Relay 2 Amp Back Box 4100U Relay 10 Amp Back Box 4100 Relay 10 Amp Back Box 4100U Relay 3 Amp Back Box 4100 Relay 3 Amp Back Box 4100U 4100 9813 is an aftermarket PID Contents Shipment unpacking your Simplex product inspect the contents of the carton for shipping damage If is apparent immediately file a claim with the carrier and notify Simplex Field Wiring Diagrams 841 731 power limited or 841 995 non power limited Fire Alarm System Installation Guide 574 848 this Publication publication discusses the following topics Page and Warnings Switches Motherboards into 2975 91xx Back Boxes 4100 Motherboards into 2975 94xx Back Boxes 4100U the Daughter Card 2001 Simplex Time Recorder Co Westminster MA 01441 0001 USA specifications and other information shown were current as of publication and are subject to change without notice A and Warnings AND SAVE THESE INSTRUCTIONS Follow the instructions in this installation These instructions must be followed to avoid damage to this product and associated Product operation and reliability depends upon proper installation NOT INSTALL ANY SIMPLEX PRODUCT THAT APPEARS DAMAGED Upon your Simplex product inspect the contents of the carton for shipping damage If is apparent immediately file a claim with the carrier and notify Simplex HAZARD Disconnect electrical field power when making any internal or repairs Servicing should be performed by qualified Simplex Representatives HAZARD Static electricity can damage components Therefore handle as follows Ground yourself before opening or installing components use the 553 484 Static Control Prior to installation keep components wrapped in anti static material at all times SAFETY HAZARD Under certain fiber optic application conditions the optical output of device may exceed eye safety limits Do not use magnification such as a microscope or other equipment when viewing the output of this device FREQUENCY ENERGY This equipment generates uses and can radiate radio energy and if not installed and used in accordance with the instruction manual may interference to radio communications It has been tested and found to comply with the for a Class A computing device pursuant to Subpart J of Part 15 of FCC Rules which are to provide reasonable protection against such interference when operated in a environment Operation of this equipment in a residential area may cause interference which case the user at his own expense will be required to take whatever measures may be to correct the interference REACCEPTANCE TEST AFTER SOFTWARE CHANGES To ensure proper operation this product must be tested in accordance with NFPA72 1996 Chapter 7 after programming operation or change in site specific software Reacceptance testing is required any change addition or deletion of system components or after any modification repair or to system hardware or wiring components circuits system operations or software functions known to be affected by a must be 100 tested In addition to ensure that other operations are not inadvertently at least 10 of initiating devices that are not directly affected by the change up to a of 50 devices must also be tested and proper system operation verified Information the following items for general information about the relay modules All relay module contacts are Form C dry contacts meaning the Common terminal is to the Normally Closed terminal when the relay coil is in the de energized state Relay operation must be programmed using the 4100 programmer Programming a relay assigning a software point type to the relay This point type determines the system to which the relay point is assigned and consequently the operation of the relay when an trouble and supervisory condition occurs Feedback loop circuits function as inputs to the system Typically they connect to a set of or NC contacts on a motor or the sail switch on a damper allowing the state of the device be monitored In some situations the state of the feedback point is used as a trigger within custom control equation allowing the system to react in one way when the contact is in one and another way when the contact is in the other position Always disconnect power from the system before installing a relay module the relay modules in an environment that is within the following 0 to 120 F 85 Relative Humidity 86 F Switches SW1 on the daughter card is a bank of eight dip switches From left to right see figure these switches are designated as SW1 1 through SW1 8 The function of these switches is follows SW1 1 This switch sets the baud rate for the serial communication line running between the Daughter card and the 4100 CPU Set this switch to ON SW1 2 through SW1 8 These switches set the card address within the 4100 FACP switches must be set to the value assigned to the card by the 4100 Programmer Refer Table 1 for a complete list of the switch settings for all of the possible card addresses a switch to the down position to turn it ON or to the up position to turn it OFF Switches 1 2 through 1 8 the Card Address Figure an Address of 3 Refer Table 1 for switch settings Rate SW 1 1 Be Set to 1 Address DIP Switch on next page Switches Continued continued 1 4100 Daughter Card Addresses 1 2 1 3 1 4 1 5 1 6 1 7 1 8 1 2 1 3 1 4 1 5 1 6 1 7 1 8