Simplex Install Instructions 4100-1292 Remote Command Center

File Preview

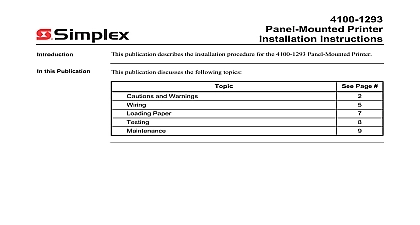

Click below to download for free

Click below to download for free

File Data

| Name | simplex-install-instructions-4100-1292-remote-command-center-3547809612.pdf |

|---|---|

| Type | |

| Size | 762.97 KB |

| Downloads |

Text Preview

4100 1292 Command Center Instructions publication describes the installation procedures for the optional 4100 1292 Remote Center RCC product is compatible with 4100U and 4100ES Fire Alarm Control Panels FACP to 4100 Field Wiring Diagrams 841 731 power limited or 841 995 non power limited additional information this Publication publication discusses the following topics Page and Warnings to the Remote Command Center 2005 2011 SimplexGrinnell LP All rights reserved and other information shown were current as of publication and are subject to change without notice and the Simplex logo are trademarks of Tyco International Ltd and its affiliates and are used under license C and Warnings and AND SAVE THESE INSTRUCTIONS Follow the instructions in this installation These instructions must be followed to avoid damage to this product and associated Product operation and reliability depend upon proper installation NOT INSTALL ANY SIMPLEX PRODUCT THAT APPEARS DAMAGED Upon your Simplex product inspect the contents of the carton for shipping damage If is apparent immediately file a claim with the carrier and notify an authorized product supplier HAZARD Disconnect electrical field power when making any internal adjust or repairs All repairs should be performed by a representative or authorized agent of local Simplex product supplier HAZARD Static electricity can damage components Handle as follows yourself before opening or installing components to installation keep components wrapped in anti static material at all times SAFETY HAZARD Under certain fiber optic application conditions the optical output this device may exceed eye safety limits Do not use magnification such as a microscope other focusing equipment when viewing the output of this device RULES AND REGULATIONS PART 15 This equipment has been tested and found to with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules limits are designed to provide reasonable protection against harmful interference when equipment is operated in a commercial environment This equipment generates uses and radiate radio frequency energy and if not installed and used in accordance with the manual may cause harmful interference to radio communications Operation of equipment in a residential area is likely to cause harmful interference in which case the will be required to correct the interference at his own expense REACCEPTANCE TEST AFTER SOFTWARE CHANGES To ensure proper system this product must be tested in accordance with NFPA 72 after any programming or change in site specific software Reacceptance testing is required after any addition or deletion of system components or after any modification repair or to system hardware or wiring components circuits system operations or software functions known to be affected by a must be 100 tested In addition to ensure that other operations are not affected at least 10 of initiating devices that are not directly affected by the up to a maximum of 50 devices must also be tested and proper system operation 72 is a registered trademark of the National Fire Protection Association to the Remote Command Center 4100 1292 Remote Command Center RCC provides annunciation and limited system for remote areas The RCC LCD can display any alarm trouble or supervisory condition RCC also provides basic user capabilities such as system reset alarm and acknowledgment supervisory and trouble indications RCC consists of the following general parts An LCD assembly with a membrane keypad The keypad has 11 switches and 10 LEDs A CPU memory card assembly that connects to the LCD assembly via two headers An internal mounting plate assembly An external panel mounting plate 1 below is an exploded diagram of the RCC with an illustration of the operator interface IS NORMAL am MON 22 MAY 00 2 Interface LCD Display with Overlay 1 The RCC on next page to the Remote Command Center Continued continued 2 below is an illustration of the 565 078 CPU Memory Card which is located at the back the RCC assembly COMM TERMINAL BLOCK TB2 V POWER TERMINAL BLOCK TB1 is the 24 V input to the RCC Its terminals are listed in Table 1 below 2 The CPU Memory Card connects to the RUI card Its terminals are listed in Table 2 below 1 TB1 C V 2 TB2 Range normal standby Current Piezo On Standby Current Piezo Backlight Off VDC 18 to 32 VDC mA maximum mA maximum mA to 49 C 32 F to 120 F to 93 at 32 C specifications below apply to all RCC components together 3 Specifications RCC can be installed into a standard 2975 94xx Back Box 4100U or 4100ES Ensure that the entire assembly is intact according to Figure 1 Align the six captive mounting screws on the 637 414 Panel Mounting Plate with six holes on the front chassis of the back box Push the mounting plate toward the cabinet so that the captive mounting screws go the mounting holes Secure the mounting plate to the back box front chassy using six 6 lockwashers and six 6 nuts 322 123 Guidelines section contains guidelines and instructions for connecting the RCC to power and wiring sure these guidelines are accounted for before wiring All wires must be 18 AWG or as the local code dictates Conductors must test free of all grounds All wiring must be done using copper conductors only unless noted otherwise shielded wire is used metallic continuity of the shield must be maintained throughout the entire cable entire length of the cable must have a resistance greater than 1 Megohm to earth Underground wiring must be free of all water areas of high lightning activity or in areas that have large power surges the Transient Suppressor should be used on monitor points Wires must not be run through elevator shafts Wires that run in plenum must be in conduit Splicing is permitted All spliced connections must either be soldered resin core solder in metal sleeves or encapsulated with an epoxy resin When soldering or metal sleeves are used the junction must be insulated with a high grade tape that is as sound as the original insulating jacket Shield continuity must be throughout A system ground must be provided for earth detection and lightning protection devices connection must comply with approved earth detection per NFPA780 Only system wiring can be run together in the same conduit Excess slack should be kept to a minimum inside the back box enclosure The wiring be neatly dressed and bundled together using the wire ties provided with the Anchor power limited wiring to tie points on next page Continued and Figure 4 and the notes below to connect the RUI card to an LCD annunciator NOTES 3 Wiring to an LCD Annunciator Class B wiring is used jumper TB1 2 to TB1 5 and TB1 4 to TB1 7 using the Harness Class A wiring is used Harness 733 716 is removed and the second pair shown dashed lines is used C