Simplex Installation Instructions IDNet+ Module

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | simplex-installation-instructions-idnet-module-0753419826.pdf |

|---|---|

| Type | |

| Size | 823.26 KB |

| Downloads |

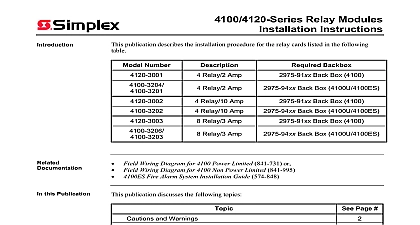

Text Preview

Module Instructions product is compatible with both 4100U and 4100ES Fire Alarm Control Panels publication describes the installation procedure for the 4100 3107 IDNet module IDNet module is specially designed for retrofit installations when existing wiring is to be Some key features include Built in Quad Isolator uses IDNet addresses 247 to 250 Supports 246 external addressable IDNet devices noise immunity eliminates the need for shielded and twisted wire in applications Duplicate Device Detection and Weak Answer Detection diagnostic feature Channel configuration diagnostic tool NOTE For use with 4100U Software Revision 11.10 or higher Verify FACP System Programmer Executive and Slave Software when installing or replacing system components to the Technical Support Information and Downloads website compatibility information this Publication publication discusses the following topics Page Warnings and Regulatory Information to the IDNet Module 1 Installing the IDNet Module into the PDI 2 Configuring the Module 3 Wiring to IDNet Peripherals an Addressable IDNet System onto Existing Wiring of Incompatible Devices Port Diagnostics 2004 2011 SimplexGrinnell LP All rights reserved and other information shown were current as of publication and are subject to change without notice and the Simplex logo are trademarks of Tyco International Ltd and its affiliates and are used under license B Warnings and Regulatory Information and AND SAVE THESE INSTRUCTIONS Follow the instructions in this installation These instructions must be followed to avoid damage to this product and associated Product operation and reliability depend upon proper installation NOT INSTALL ANY SIMPLEX PRODUCT THAT APPEARS DAMAGED Upon your Simplex product inspect the contents of the carton for shipping damage If is apparent immediately file a claim with the carrier and notify an authorized product supplier HAZARD Disconnect electrical field power when making any internal adjust or repairs All repairs should be performed by a representative or authorized agent of local Simplex product supplier SAFETY HAZARD Under certain fiber optic application conditions the optical output this device may exceed eye safety limits Do not use magnification such as a microscope other focusing equipment when viewing the output of this device HAZARD Static electricity can damage components Handle as follows yourself before opening or installing components to installation keep components wrapped in anti static material at all times RULES AND REGULATIONS PART 15 This equipment has been tested and found to with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules limits are designed to provide reasonable protection against harmful interference when equipment is operated in a commercial environment This equipment generates uses and radiate radio frequency energy and if not installed and used in accordance with the manual may cause harmful interference to radio communications Operation of equipment in a residential area is likely to cause harmful interference in which case the will be required to correct the interference at his own expense REACCEPTANCE TEST AFTER SOFTWARE CHANGES To ensure proper operation this product must be tested in accordance with NFPA 72 after any operation or change in site specific software Reacceptance testing is required any change addition or deletion of system components or after any modification repair adjustment to system hardware or wiring components circuits system operations or software functions known to be affected by a must be 100 tested In addition to ensure that other operations are not inadvertently at least 10 of initiating devices that are not directly affected by the change up to a of 50 devices must also be tested and proper system operation verified Introduction to the IDNet Module 4100 3107 IDNet module shown below provides a single IDNet channel with four isolated circuits allowing the System CPU to communicate with up to 246 IDNet peripherals such smoke detectors and pull stations Each IDNet Circuit A B C and D is individually isolated the IDNet module in case of a short circuit If a short circuit occurs on one or more output the short circuits are isolated and do not affect IDNet channel communications on other circuit has terminations for Class A or Class B wiring selected by the configuration of two Class B wiring requires the configuration jumpers set to Position 1 2 see Figure 1 required the IDNet module is capable of supporting both Class A and B Circuits When for Class B operation the B B and A A Terminals are on the IDNet and may be used for connecting to IDNet devices on separate runs such as the existing wiring in a retrofit installation see B Wiring section later in this publication module is a flat 8 by 5 9 16 204 mm x 144 mm option module that plugs into the Distribution Interface PDI The IDNet module built in Quad Isolator uses IDNet Point Addresses 247 to 250 CIRCUIT A CIRCUIT B CIRCUIT C CIRCUIT D View P1 2 3 A Wiring 1 2 B Wiring LED Location Module Switch Connector on back of Board A B Circuit Jumpers to Position 1 2 for Class B Wiring Position 2 3 for Class A Wiring 4 2 1 3 4 5 6 7 8 POS HDR ON SOLDER SIDE 1 The 4100 3107 IDNet Module Module LEDs IDNet module has the following status indicating LEDs Trouble Indicator 2 Normally OFF Turns ON steady if the IDNet module is not communicating with Trouble Indicators 1 Normally OFF ON steady indicates a channel failure no devices talking on any of CPU four circuits 3 ON steady indicates a Circuit A Fault Open or Short 4 ON steady indicates a Circuit B Fault Open or Short 5 ON steady indicates a Circuit C Fault Open or Short 6 ON steady indicates a Circuit D Fault Open or Short on next page to the IDNet Module Continued Limitations 1 General System Specifications Specifications VDC from FACP Input Voltage IDNet Remote VDC normal 36 VDC maximum 350 mA alarm or when activating large quantity of device outputs output voltage is increased to 36 VDC rate is 3333 bps circuits are supervised and power limited AWG 0.82 mm2 minimum to 12 AWG 3.31 mm2 maximum Sizes Parameters Refer to details on page 8 Device Control Piezo Support IDNet module tracks which remote device LEDs if should be on and can activate up to 20 at one time to 43 coded piezo tone alert sounders are supported by one channel Specifications to 120 F 0 to 49 C to 93 relative humidity at 94 F 38 C 1 Installing the IDNet Module into the PDI 4100 3107 IDNet module mounts on a PDI in an Expansion bay It can be mounted on any the PDI connectors with an adjacent empty slot The IDNet module consumes two slots side by side Only two IDNet modules can be in a single bay and only two IDNet modules are allowed on the same module tap Due to a symmetrical PDI connector design the module can be mounted with terminals up or down to allow proper location with adjacent modules three screws standoffs be connected connections 3 Screws 3 Module 2 Mounting onto the Power Distribution Interface PDI 4100U Shown PDI connector located on the reverse side of the IDNet module must be mated with one of PDI receptacles The IDNet module mounts in either the to