System Sensor AFDT and AFDTH Manual

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | system-sensor-afdt-and-afdth-manual-4530179826.pdf |

|---|---|

| Type | |

| Size | 695.55 KB |

| Downloads |

Text Preview

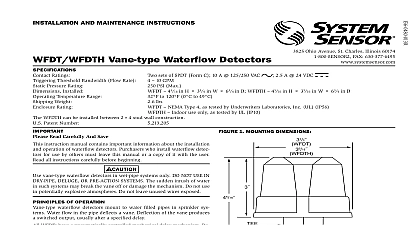

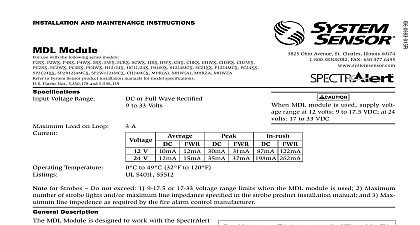

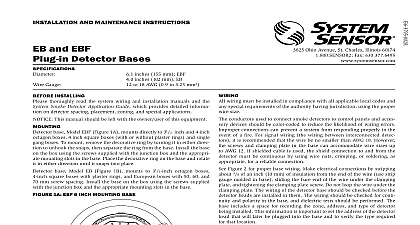

INSTALLATION AND MAINTENANCE INSTRUCTIONS Accuflow Waterflow Detectors Solid State Retard Ratings Threshold Bandwidth Rate Pressure Rating Installed Temperature Range 32 120 0 49 Weight Rating lbs A 125 VAC 2 A 30 VDC GPM PSI Max 33 63 39 63 Type 4 as tested by Laboratories Inc use only as tested by U L V DC 108 VAC at 12 or 24 V DC at 120 VAC 6,084,521 6,275,160 Range Requirements Patent Number Read Carefully And Save instruction manual contains important information about the and operation of waterflow detectors Purchasers who waterflow detectors for use by others must leave this man or a copy of it with the user Read all instructions carefully beginning vane type waterflow detectors in wet pipe systems only DO USE IN DRY PIPE DELUGE OR PRE ACTION SYSTEMS The inrush of water in such systems may break the vane off or the mechanism Do not use in potentially explosive Do not leave unused wires exposed Of Operation waterflow detectors mount to water filled pipes in systems Water flow in the pipe deflects a vane of the vane produces a switched output usually after specified delay AFDTs have a controlled delay mechanism Delays are noncu they reset if the flow of water stops before the entire has elapsed All detectors will activate on a sustained flow water greater than 10 gallons per minute gpm but will not if the flow rate is less than 4 gpm Pipe Tees Risers AFDT and AFDTH fit 1 to 11 NPT threaded ferrous and 1 to 2 sweat brass 11 polybutylene plastic and 1 cpvc tees having a 1 threaded NPT branch see Figure 1 and for recommended tee depths For 2 cast and malleable tees use 2 paddle P02 0023 000 provided Ohio Avenue St Charles Illinois 60174 FAX 630 377 6495 AFDTH can be installed between 2X4 stud wall construction Compatibility AFD waterflow indicators may receive power and operate on two wire initiating zone of a fire alarm control panel When compatibility of these devices the standby operating of the control panel must be between 8.5 and 35 volts In standby mode the AFD draws a maximum current of 0.3 mA alarm the AFD acts as a short across the initiating zone sim to a manual fire box For two wire conventional fire alarm panels not more than 5 waterflow indicators may be to a single initiating zone The maximum retard reset of the waterflow indicator plus the initiating zone shall not 90 seconds two wire addressable control panels the number of water indicators connected to the panel signaling line circuit be limited only by the circuit current capacity Tee Depth Requirements Figure 1 Depth Threaded Sweat Poly B CPVC 1 1 11 4 1 11 2 1 2 1 1 Mounting dimensions Adapter Depth to Depth End of Paddle Tree Fit Between Top of and Bottom of Flange Fitting Vane Guidelines installing any waterflow alarm device be thoroughly with 72 13 13D Fire Alarm Code of Sprinkler Systems for 1 and 2 Family Dwellings and Homes for Residential Occupancies up to and Four Stories in Height Testing and Maintenance of Water Fire Protection Systems 13R 25 follow other applicable NFPA standards local codes and the of the authority having jurisdiction Installation methods other than those listed in this manual may prevent the device from reporting flow of water in the event the associated sprinkler is activated by a fire System Sensor is not for devices that have been improperly tested or maintained Mount the detector where there is adequate clearance for and removal and a clear view of it for inspection Figure 1 for mounting dimensions 2 Assembly diagram PROOF P N WFDW SWITCH SCREW NPT THREAD P N PRK9 ONLY Locate the detector 6 to 7 feet above the floor to protect from damage On horizontal runs position the detector on top of the pipe or the side of it Do not mount it upside down because con may collect in the housing and impair the operation the detector For vertical flow applications mount detector pipe where upflow conditions exist Failure to do so may unit from operating properly Mount detector at least 6 inches from a fitting which changes direction of the water flow or no closer than 24 inches a valve or drain BE SURE DIRECTION OF FLOW ARROW MATCHES ACTUAL OF FLOW IN THE PIPE Instructions The AFDT and AFDTH waterflow detectors are designed to fit the appropriate tee fitting of tee perpendicular to flow of water must have a 1 thread Do not use a reducer to achieve the correct size Failure to follow this instruction will result failure of the detector to report a waterflow condition AFDT and AFDTH units are shipped without paddles mounted the actuator Select the correct size paddle for the type of tee used Align hole on stem of paddle with hole on actua lever Fasten together using a 4 40 x 1 4 fillister head supplied in bag assembly See Figure 2 Use only the provided with the unit Drive screw head through hole paddle until it seats to actuator lever surface No washer is For paddle replacement refer to Maintenance section Carefully roll the vane opposite the direction of flow and insert tee Thread detector onto tee fitting and tighten with Use of thread sealant or tape is recommended Use gage located at end of paddle tree to ensure proper of detector on tee fitting See Figure 1 Height gage must between top of tee fitting and under side of hex tee adapter gap between gage and tee adapter is acceptable When cor installed the detector must face in the proper direction waterflow and be aligned with the pipe Remove the metal cover Move the actuator lever back and to check for binding If the vane binds remove the detec and correct the problem before proceeding sure the direction of flow arrow points in the right direction a waterflow condition will go unreported See Figure 2 the sprinkler system with water and check for leaks around AFDT or AFDTH If there is a leak check to see that the fit are tight If leak persists drain the system and remove the see removal instructions under Maintenance Check for threads or cracked fitting Reinstall the detector and again for leaks Do not proceed until all leaks have been Voltage Electrocution Hazard Do not handle live AC wiring or on a device to which AC power is applied Doing so may result injury or death All models have two wires and two sets of terminals Wires W1 W2 designated on PCB These wires are to a latching normally open as in No Flow relay They are isolated from all electronics They will close cause a short when water flows and the retard time elaps They will remain shorted until waterflow stops Once water stops these contacts will re open Terminals T2 designated on PCB This is a TWO terminal block The Accuflow gets its power from these These terminals must have voltage present fro