System Sensor b210lp Install and Maint Instructions

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | system-sensor-b210lp-install-and-maint-instructions-7326159480.pdf |

|---|---|

| Type | |

| Size | 697.36 KB |

| Downloads |

Text Preview

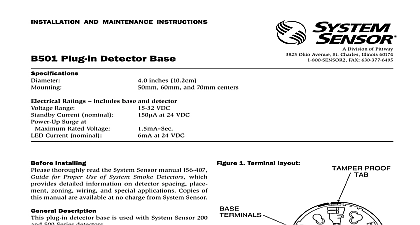

INSTALLATION AND MAINTENANCE INSTRUCTIONS Plug in Detector Base use with the following models US Canada 2251 2251A SENSOR Division of Pittway 3825 Ohio Avenue St Charles Illinois 60174 FAX 630 377 6495 inches 155 mm inch 102 mm square box with or without plaster ring Depth 1.5 inches 38 mm inch Octagon Box Min Depth 1.5 inches 38 mm inch Octagon Box Min Depth 1.5 inches 38 mm Gang Box Min Depth 1.5 inches 38 mm 1 Terminal layout PROOF A78 1318 00 Installing thoroughly read the system wiring and installation and manual I56 407 Guide for Proper Use of Sys Smoke Detectors which provides detailed information detector spacing placement zoning and special appli Copies of these manuals are available from System or through a System Sensor distributor For installa in Canada refer to CAN ULC S524 Standard for the of Fire Alarm Systems and CEC Part 1 Sec 32 Description Plug in Detector Base is used with System Sensor mod 1251 and 1251A ionization and 2251 and 2251A photo detectors B210LP base is intended for use in a 2 wire intelli system with screw terminals provided for power and and remote annunciator connections Com takes place over the power and lines Terminals Remote Annunciator Annunciator detector base mounts directly to 3 1 2 inch and 4 inch boxes 4 inch square boxes with or without plas rings and single gang boxes To mount remove the ring by turning it in either direction to unhook snaps then separate the ring from the base Install the on the box using the screws supplied with the junc box and the appropriate mounting slots in the base Manuals Online the decorative ring on the base and rotate it in either until it snaps into place see Figure 2 2 Mounting detector to box Wiring Guidelines wiring must be installed in compliance with all appli local codes and any special requirements of the au having jurisdiction using the proper wire size The used to connect smoke detectors to control pan and accessory devices should be color coded to reduce likelihood of wiring errors Improper connections can a system from responding properly in the event of a signal wiring the wiring between interconnected de it is recommended that the wire be no smaller AWG 18 However the screws and clamping plate in base can accommodate wire sizes up to AWG 12 The of twisted pair wiring or shielded cable for the power and loop is recommended to minimize the effects of interference shielded cable is used the shield connection to and from detector must be continuous by using wire nuts crimp or soldering as appropriate for a reliable connection electrical connections by stripping about 3 8 10 of insulation from the end of the wire use strip gauge in base sliding the bare end of the wire under the plate and tightening the clamping plate screw not loop the wire under the clamping plate zone wiring of the detector base should be checked the detector heads are installed in them The wiring be checked for continuity and polarity in the base dielectric tests should be performed base includes a label for recording the zone address type of detector being installed This information is im to set the address of the detector head that will be plugged into the base and to verify the type re for that location ON NOT NOT Manuals Online 3 Typical Wiring Diagram for 2 wire loop ANNUNCIATOR Do not loop wire under terminal 1 or 2 wire run to provide supervision of connections A OPTIONAL WIRING Feature Do NOT use the tamper resistant capability if the Removal Tool will be used Tamper Resistant Tab in the Detector Mounting can make the detector tamper resistant by making necessary to use a small screwdriver or similar tool to de the detector from the base make the detector tamper resistant use needle nose pli to break the smaller tab at the scribed line on the resistant tab Figures 1 and 4A show the location of tab on the detector mounting bracket remove the detector from the base after it has been tamper resistant remove the decorative ring by rotat it in either direction and pulling it away from the base insert a small screwdriver into the notch as indi in Figure 4B and press the plastic lever toward the surface before rotating the detector counterclock for removal 4A Enabling the tamper resistant capability Removing the detector head from the base LEVER TAB AT LINE BY TOWARD OF BASE SMALL BLADED TO PLASTIC LEVER DIRECTION OF L n l JI Manuals Online Annunciator Model RA400Z the remote annunciator between terminals 1 and 3 the spade lug terminal included The spade lug termi is connected to the base terminal as shown in Figure 5 is not acceptable for three stripped wires to be under the wiring terminal unless they are separated by a or a lug like the spade lug supplied with the model See Figure 5 for installation 5 Connection to remote annunciator terminal WIRE WITH LUG Limitations of Property Protection Smoke Detectors smoke detector used with this base is designed to activate and ini emergency action but will do so only when it is used in conjunction an authorized fire alarm system This detector must be installed in with NFPA standard 72 detectors will not work without power AC or DC powered detectors will not work if the power supply is cut off detectors will not sense fires which start where smoke does not the detectors Smoldering fires typically do not generate a lot of which is needed to drive the smoke up to the ceiling where the detector is usually located For this reason there may be large de in detecting a smoldering fire with either an ionization type detector a photoelectric type detector Either one of them may alarm only after has initiated which will generate the heat needed to drive the to the ceiling from fires in chimneys in walls on roofs or on the other side of a door s may not reach the smoke detector and alarm it A detector detect a fire developing on another level of a building quickly or at For these reasons detectors shall be located on every level and in bedroom within a building detectors have sensing limitations too Ionization detectors and detectors are required to pass fire tests of the flaming and type This is to ensure that both can detect a wide range of of fires Ionization detectors offer a broad range of fire sensing capa but they are somewhat better at detecting fast flaming fires than smoldering fires Photoelectric detectors sense smoldering fires better flaming fires which have little if any visible smoke Because fires de in different ways and are often unpredictable in their growth nei type of detector is always best and a given detector may not always early warning of a specific type of fire general detectors cannot be expected to provide warnings for fires re from inadequate fire protection practices violent explosions es gases which ignite improper storage of flammable liquids like solvents which ignite other similar safety hazards arson smok in bed children playing with matches or lighters etc Smoke detectors in high air velocity conditions may have a delay in alarm due to dilu of smoke densities created by frequent and rapid air exchanges Addi high air velocity environments may create increased dust demanding more frequent maintenance detectors cannot last forever Smoke detectors contain ele