System Sensor D4120, D4P120, and D4S Manual

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | system-sensor-d4120-d4p120-and-d4s-manual-0543679128.pdf |

|---|---|

| Type | |

| Size | 2.40 MB |

| Downloads |

Text Preview

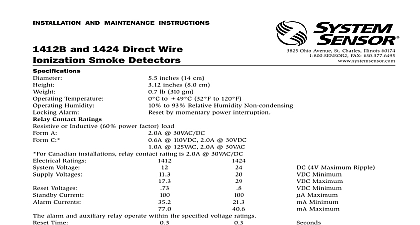

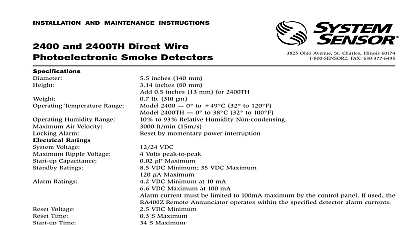

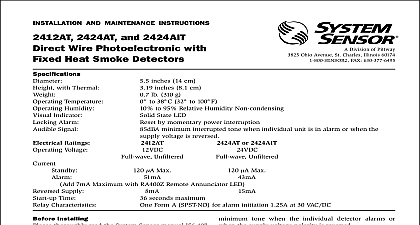

I AND MAINTENANCE INSTRUCTIONS 3825 Ohio Avenue St Charles Illinois 60174 FAX 630 377 6495 D4S to 158 F to 70 C D4P120 to 158 F to 70 C D4S to 158 F to 70 C D4P120 to 158 F to 70 C to 95 Relative Humidity Non condensing to 4000 ft min 0.5 to 20.3 m sec 14.38 in L x 5 in W x 2.5 in D 37cm L x 12.7cm W x 6.36cm D 7.75 in L x 9 in W x 2.5 in D 19.7cm L x 22.9cm W x 6.35cm D Duct Smoke Detector Sensor Component Power Board Component The D4120 duct detector consists of D4P120 Power Board component and the D4S Sensor component Temperature Temperature Velocity Footprint Dimensions Footprint Dimensions 7.75 in L x 5 in W x 2.5 in D 19.7cm L x 12.7cm W x 6.35cm D Weight VDC supply voltage max capacitance Voltage VDC min Time with RTS451 RTS151 03 to 0.3 sec sec max Time by power down sec max Up Time sec response time Test detector label Requirements Using No Accessories standby current alarm current VAC 50 60 Hz max VAC min to 0.3 sec sec max sec max sec detector label mA RMS 24VAC 60Hz mA RMS 24 VAC 60 Hz mA 24 VDC mA 24 VDC pounds 1.14 kg VAC 50 60 Hz VAC min to 0.3 sec sec max sec max sec detector label mA RMS 120 VAC 60 Hz mA RMS 120 VAC 60 Hz RATINGS initiation contacts SPST 30 VDC resistive auxiliary contatcs DPDT 30 VDC resistive 250 VAC resistive HP 240 VAC HP 120 VAC Alarm auxiliary contacts shall not be connected to initiating circuits of panels Use the alarm initiation contact for this purpose Contacts SPDT 30 VDC resistive 125 VAC resistive OF CONTENTS Limitations of Duct Smoke Detectors 1 Exploded View of Duct Smoke Detector Components 2 General Description 2 Contents of Duct Smoke Detector Kit 2 Detector Installation 2 Sampling Tube Installation 3 Measurement Tests 3 Field Wiring Installation Guidelines 4 Unit Configuration 5 Detector Status Indication 6 Interconnection Multiple Fan Shut Down 6 Verification of Operation 6 Detector Cleaning Procedures 7 Sensor replacement 7 Optional Accessories 7 Diagrams 5 7 8 INSTALLING System Sensor Applications Guide for Duct Smoke Detectors which provides information on detector spacing placement wiring and special applications This manual is available online at NFPA Standards 72 and 90A should also be refer for detailed information This manual shall be left with the owner user of this equipment Max Max Max Max Max Max CURRENT LOADS AT 24 VDC Max Max Max Max Any combination of accessories may be used such that the given accessory are 110mA or less at the Aux output and 50mA or less at the Alarm output This detector must be tested and maintained regularly following 72 requirements The detector must be tested an maintained regularly fol NFPA 72 requirements According to NFPA the detector should be visu inspected semiannually and functionally tested at least once a year This need to be more frequent depending on the air quality of the duct supply air LIMITATIONS OF DUCT SMOKE DETECTORS National Fire Protection Association has established that DUCT DETEC MUST NOT BE USED AS A SUBSTITUTE FOR OPEN AREA DETECTOR as a means of providing life safety Nor are they a substitute for warning in a building regular fire detection system Sensor supports this position and strongly recommends that the user NFPA Standards 90A 72 and 101 The D4120 Air Duct Smoke Detectors listed per UL 268A device will not operate without electrical power Fire situations may an interruption of power The system safeguards should be discussed your local fire protection specialist device will not sense smoke unless the ventilation system is operating the cover is installed this detector to function properly it MUST be installed according to the in in this manual Furthermore the detector MUST be operated within electrical and environmental specifications listed in this manual Failure comply with these requirements may prevent the detector from activating smoke is present in the air duct FIGURE 1 EXPLODED VIEW OF DUCT SMOKE DETECTOR COMPONENTS TUBE TUBE seperately HEAD TEST LOCATION GENERAL DESCRIPTION introduced into an air duct system will be distributed throughout the building Smoke detectors designed for use in air duct systems are used sense the presence of smoke in the duct D4120 and D4S Duct Smoke Detectors utilize 4 wire photoelectric tech for the detection of smoke This detection method when combined an efficient housing samples air passing through the duct allowing de of a developing hazardous condition When sufficient smoke is sensed alarm signal is initiated and appropriate action can be taken to shut off blowers change over air handling systems etc These actions can fa the management of toxic smoke and fire gases throughout the areas by the duct system D4120 and D4P120 detectors are designed to operate on 24 VDC VAC or VAC Alarm and supervisory relay contacts are available for control panel alarm initiation HVAC control and other auxiliary functions Aux relays are provided for fan shut down Detector interconnection provides of up to 50 other detectors in the loop for multiple fan shut down detectors are not designed for 2 wire applications DETECTOR FEATURE SET 2D51 plug in head sensors to 1 power board capability missing signal tubes install from front or rear of detector with existing accessories CONTENTS OF THE DUCT SMOKE DETECTOR KIT board assembly and cover s Three 10 sheet metal screws for mounting Drilling template One sampling tube end cap One plastic exhaust tube A sampling tube must be ordered to complete the installation It must the correct length for the width of the duct where it will be installed Table 1 on page 3 to determine the inlet tube required for different duct DETECTOR INSTALLATION VERIFY AIR FLOW DIRECTION AND VELOCITY D4120 detectors are designed to be used in air handling systems with velocities of 100 to 4000 feet per minute Duct widths from 6 inches to 12 can be accommodated Be sure to check engineering specifications to that the air velocity in the duct falls within these parameters If neces use a velocity meter anemometer to check the air velocity in the duct DETERMINE MOUNTING LOCATION AND CONFIGURATION ducts wider than 18 inches it is recommended that the detector be downstream of a bend obstruction in the duct or the supply or air inlet Installation of duct detectors can be on or within a commercial BOARD BOARD MODULE COVER MODULE rooftop heating and air conditioning system fi