System Sensor L-Series 4-Wire Horn Strobes - Wall (I56-6515)

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | system-sensor-l-series-4-wire-horn-strobes-wall-i56-6515-1984627530.pdf |

|---|---|

| Type | |

| Size | 1.63 MB |

| Downloads |

Text Preview

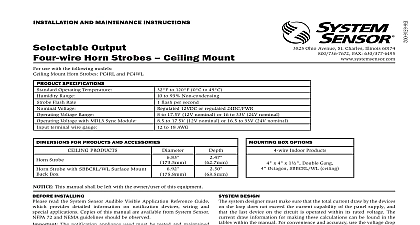

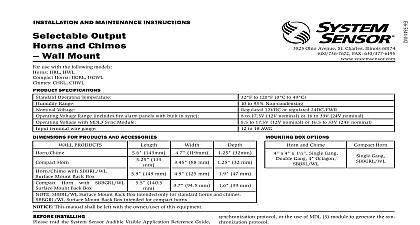

I Ohio Avenue St Charles Illinois 60174 FAX 630 377 6495 AND MAINTENANCE INSTRUCTIONS Output Horn Strobes Wall Mount use with the following models Wall Mount Horn Strobes P4RL P4WL SPECIFICATIONS Operating Temperature Range Flash Rate Voltage Voltage Range Voltage with MDL3 Sync Module 8.5 to 17.5V 12V nominal or 16.5 to 33V 24V nominal terminal wire gauge FOR PRODUCTS AND ACCESSORIES to 120 0 to 49 to 93 Non condensing flash per second 12VDC or regulated 24DC FWR to 17.5V 12V nominal or 16 to 33V 24V nominal to 18 AWG PRODUCTS Horn Strobe 143mm 119mm 32mm device with SBBRL WL Surface Mount Back Box 149 mm 125 mm 47 mm SBBRL WL Surface Mount Back Box intended for standard horn strobes BOX OPTIONS 4 Wire Indoor Products x 4 x 1 Double Gang 4 Octagon SBBRL WL wall This manual shall be left with the owner user of this equipment INSTALLING read the System Sensor Audible Visible Application Reference Guide provides detailed information on notification devices wiring and applications Copies of this manual are available from System Sensor 72 and NEMA guidelines should be observed The notification appliance used must be tested and maintained NFPA 72 requirements DESCRIPTION Sensor series of notification appliances offer a wide range of audible visible devices for life safety notification Our 4 wire horn strobes come 10 field selectable tone and volume combinations and 7 field select candela settings Intended for indoor applications and approved for wall installations only horn strobes are public mode notification appliances intended to alert of a life safety event The horn is listed to ANSI UL 464 require public mode and the strobe is listed to ANSI UL 1638 public mode Sensor notification appliances are designed to be used in either 12 24VDC or 24V FWR full wave rectified systems System Sensor AV de can be activated by a compatible fire alarm control panel or power sup Refer to the appropriate fire alarm control panel manufacturer or power for more information Sensor wall 4 wire horn strobes are electrically backward compat with the previous generation since 1996 of notification appliances come enabled with System Sensor synchronization protocol which re connections to a power supply capable of generating the System Sen synchronization pulses a FACP NAC output configured to System Sensor protocol or the use of MDL3 module to generate the syn protocol ALARM SYSTEM CONSIDERATIONS National Fire Alarm and Signaling Code NFPA 72 requires that all noti appliances used for building evacuation installed after July 1 1996 temporal coded signals Signals other than those used for evacuation do not have to produce the temporal coded signal System Sensor spacing notification appliances in compliance with NFPA 72 DESIGN system designer must make sure that the total current draw by the devices the loop does not exceed the current capability of the panel supply and the last device on the circuit is operated within its rated voltage The draw information for making these calculations can be found in the within the manual For convenience and accuracy use the voltage drop on the System Sensor website www systemsensor com calculating the voltage available to the last device it is necessary to the voltage due to the resistance of the wire The thicker the wire the the voltage drop Wire resistance tables can be obtained from electri handbooks Note that if Class A wiring is installed the wire length may up to twice as long as it would be for circuits that are not fault tolerant total number of strobes on a single NAC must not exceed 69 for 24 volt TONES Sensor offers a wide variety of tones for your life safety needs includ temporal 3 pattern second on second off second on second second on 1 off and repeat which is specified by ANSI and NFPA 72 standard emergency evacuation signaling select the tone turn the rotary switch on the back of the product to the de setting See Figure 1 Available horn settings and sound output ratings be found in Table 1 The standard mini horn sound is 3.1 kHz The legacy sound of the Advance line is EM Electro mechanical this hops frequencies 2Hz and 4Hz For EM Coded positions temporal coding must be by the NAC If the NAC voltage is held constant the horn output will constantly on 1 AUDIO SELECTOR Setting 3 LIGHT OUTPUT DISPERSION 4 VERTICAL WALL TO FLOOR of of 1 HORN TONES kHz Temporal kHz Temporal kHz Non Temporal kHz Non Temporal kHz Coded CANDELA SETTINGS Sensor offers a wide range of candela settings for your life safety In order to select your candela output adjust the slide switch on the of the product to the desired candela setting on the selector switch See 2 candela setting can also be verified by looking into the small window on front of the unit See Table 2 for candela settings for wall products All meet the light output profiles specified in the appropriate UL Stan See Figures 3 and 4 2 CANDELA SELECTOR 45 the left 45 the right is generated text for of degree is permitted DRAW AND AUDIBILITY RATINGS 4 wire device provides two independent circuits one for the Horn and for the Strobe The current draw for each Strobe setting is listed in 3 and audibility ratings for each Horn Tone setting is listed in Table 4 3 WALL MOUNT STROBE CURRENT DRAW mA Volts Products set at 15 and 30 automatically work on ei 12V or 24V power supplies products are not listed for DC operation when set to any candela settings 4 HORN CURRENT DRAW mA AND SOUND OUTPUT REVERBERANT DBA Volts Output dBA V kHz Temporal kHz Temporal Settings 9 and 10 are not available on 2 wire horn strobes Temporal coding must be provided by the If the NAC voltage is held constant the horn output remains constantly on kHz Non Temporal kHz Non Temporal kHz Coded AND REMOVING APPLIANCE Attach mounting plate to junction box See Figure 7 Connect field wiring according to terminal designations See Figures 5 and 6 If the product is not to be installed at this point use the protective dust to prevent contamination of the wiring terminals on the mounting plate To attach product to mounting plate a Remove the protective dust cover b Hook the tabs on the top of the product housing into the grooves on plate c Pivot the product into position to engage the terminals on the mounting Make sure that the tabs on the back of the product housing fully with the mounting plate d Hold product in place with one hand and secure product by tightening the mounting screw in the front of the product housing A SURFACE MOUNT BACK BOX The surface mount back box may be secured directly to the wall or ceiling of grounding bracket wit