System Sensor Manufacturer's Methods for Duct Smoke Detector Testing

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | system-sensor-manufacturer-s-methods-for-duct-smoke-detector-testing-1692573084.pdf |

|---|---|

| Type | |

| Size | 595.55 KB |

| Downloads |

Text Preview

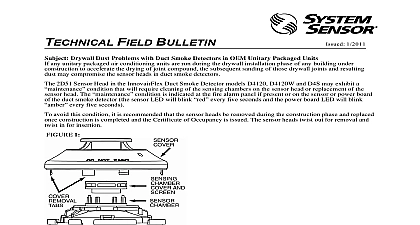

Technical Field Bulletin Manufacturer methods for duct smoke detector testing of System Sensor duct smoke detectors Application Engineers 10 98 1 04 codes and local safety standards recognize the ability of air duct systems to transfer smoke toxic gases and flames from area area Enormous quantities of smoke can be a serious hazard to life safety unless blowers are shut down and or dampers are closed primary purpose of duct mounted smoke detection therefore is to prevent injury panic and property damage by reducing the of smoke Please note that the NFPA 72 National Fire Protection Association has established that duct detectors shall not be as a substitute for open area smoke detectors Chap 5.14.2 a 2002 ed of duct smoke detectors with smoke provides a unique challenge The quantity of smoke required to produce the proper is dependent upon multiple environmental conditions such as size of the duct air velocity humidity air stratification air and response In addition the smoke that must be generated is many times greater than actually required to cause an open spot type detector to alarm It may require that the building be subjected to an actual fire test any testing is performed verify that the duct smoke detector is installed per NFPA 72 guidelines and in accordance with the installation instructions procedure for testing System Sensor duct mounted smoke detectors is as follows The built in test feature i e the test magnet test switch etc should be performed These features are designed to meet the intent the NFPA and Underwriters Laboratories functional test requirements to electronically or mechanically simulate gray smoke to exceed 6 ft obscuration This will assure the detector is operable and will respond to minimum smoke requirements When attempting to verify that the detector will respond to smoke in the duct airflow the pressure differential should be across the sampling tubes exhaust intake using a manometer This is the manufacturer acceptable test Next apply smoke directly to the detector head to initiate an alarm The sampling and exhaust tubes may need to be blocked off this test and then reopened afterwards bomb is not a recommended test method for ionization duct smoke detectors Based on experience with in house and field of ionization duct mounted smoke detectors smoke bombs are not recommended for smoke testing purposes for the following Ionization smoke detectors are most sensitive to smoke particles ranging in size from 01 to 3 microns Particles out of this range lead to a slower than usual response In addition the particles tend to become larger the farther they travel from the source There are various problems created when using smoke bombs The smoke generated is a chemical reaction and does not represent true smoke composition or fire signature for smoke detector activation They produce cold smoke particles which are larger and not easily detected by ionization smoke detectors These particles are also dependent on relative humidity distance traveled the source and time of activation This phenomenon is caused by the smoke being a mist rather than suspended solids in gases It is also possible to pass a smoke bomb test and be out of the required manometer range for sampling giving the installer a false of proper operation The manometer test must be performed a smoke bomb to test ionization smoke detectors is not advised because this procedure does not provide a consistent method of determining if the detectors are performing properly If a smoke bomb test must be done the use of a smoke detector is highly recommended Photoelectric smoke detectors typically respond to smoke particles of 3 to 10 in size which are within the characteristics of particles generated by a smoke bomb smoke is irritating to breathing passages Persons with respiratory ailments should not be exposed to smoke bombs It is recommended that self contained breathing apparatus be used for exposure to dense concentrations of smoke or prolonged of lighter smoke density Always refer to and follow the manufacturer instructions you have any questions concerning System Sensor products or their application contact Technical Services at 1 800 SENSOR2 736 7672 extension 2 Ohio Avenue St Charles IL 60174 Phone 800 736 7672 Fax 630 377 6583 www systemsensor com