System Sensor Pipe Network Cleaning and Maintenance Instructions

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | system-sensor-pipe-network-cleaning-and-maintenance-instructions-5387604291.pdf |

|---|---|

| Type | |

| Size | 675.69 KB |

| Downloads |

Text Preview

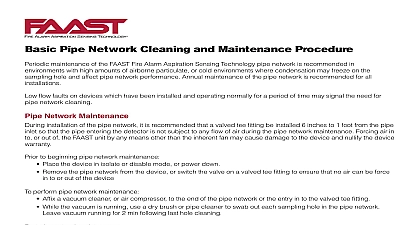

Basic Pipe Network Cleaning and Maintenance Procedure maintenance of the FAAST Fire Alarm Aspiration Sensing Technology pipe network is recommended in with high amounts of airborne particulate or cold environments where condensation may freeze on the hole and affect pipe network performance Annual maintenance of the pipe network is recommended for all flow faults on devices which have been installed and operating normally for a period of time may signal the need for network cleaning Network Maintenance installation of the pipe network it is recommended that a valved tee fitting be installed 6 inches to 1 foot from the pipe so that the pipe entering the detector is not subject to any flow of air during the pipe network maintenance Forcing air in or out of the FAAST unit by any means other than the inherent fan may cause damage to the device and nullify the device to beginning pipe network maintenance Place the device in isolate or disable mode or power down Remove the pipe network from the device or switch the valve on a valved tee fitting to ensure that no air can be force to or out of the device perform pipe network maintenance Affix a vacuum cleaner or air compressor to the end of the pipe network or the entry in to the valved tee fitting While the vacuum is running use a dry brush or pipe cleaner to swab out each sampling hole in the pipe network vacuum running for 2 min following last hole cleaning pipe network maintenance Reconnect pipe network to the FAAST device or switch the valved tee tap Remove the device from isolate or disable mode or reapply power to the FAAST Observe the air flow pendulum on the user interface The two green indicators should be near center underneath device power indicator If a low condition existed before maintenance this condition should be clear after NOTE if the device is set to latch in fault the device will need to be reset to clear the fault If the low flow condition persists perform another manual check of the pipe network against the pipe layout report by PipeIQ Also if the exhaust pipe is not situated in the protected space the low high flow condition could be result of differences in room pressures that have changed do to open doors windows or upgrades to ventilation units Maintenance maintenance is required only when a fault is indicated by the FAAST unit Perform the following procedure to the filter assembly Remove power from the system Open the door on the right side of the device that covers the LED system indicators Remove the plastic name card over the LEDs Remove the two screws holding the filter assembly into the device Remove the filter assembly and replace it with a new assembly Torque the two Philips head screws to 6in lb 0.7 N M or turn past snug NOT OVERTIGHTEN Replace the plastic name card over the LEDs Close the door and restore power to the system System Sensor Product specifications subject to change without notice 1 14