Wheelock Exceder LED3 blue lens strobe install sheet, ceiling

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | wheelock-exceder-led3-blue-lens-strobe-install-sheet-ceiling-8342519607.pdf |

|---|---|

| Type | |

| Size | 1.49 MB |

| Downloads |

Text Preview

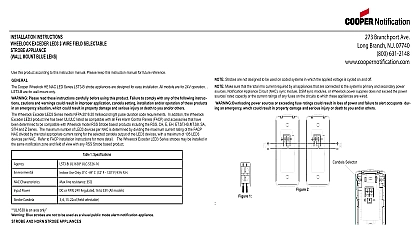

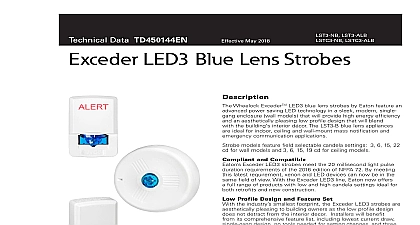

INSTALLATION INSTRUCTIONS EXCEDER LED3 CEILING MOUNT STROBES LENS this product according to this instruction manual Please keep this instruction manual for future reference Wheelock Exceder LSTC3 B strobe appliances are designed for easy installation All models are for 24V operation LSTC3 B is for ceiling mounting only Please read these instructions carefully before using this product Failure to comply with any of the following in cautions and warnings could result in improper application candela setting installation and or operation of these in an emergency situation which could result in property damage and serious injury or death to you and or others Wheelock Exceder LED3 Series meets NFPA 2016 20 millisecond light pulse duration code requirements In addition the Exceder LED3 product line has been UL ULC listed as compatible with all Fire Alarm Control Panels FACP and acces that have been determined to be compatible with Wheelock model RSS Strobe based products including the RSS CH E EH SA STH and Z Series The maximum number of LED3 devices per NAC is determined by dividing the maximum rating of the FACP NAC divided by the total appropriate current rating for the selected candela output of the LED3 devices with maximum of 105 LED3 devices per NAC Refer to FACP installation instructions for more detail The Wheelock Exceder LED3 strobes may be installed in the same notification zone and field of view with any RSS Strobe based product Characteristics Power Candela 1 Specifications UL1638 ULC 526 16 Use Only 0 C 49 C 32 F 120 F 93 R H line resistance 35 or FWR 24V Regulated 16 to 33V All models field selectable is an on axis rating Blue strobes are not to be used as a visual public mode alarm notification appliance Exceder LED3 Strobes can provide a non synchronized strobe appliance when connected directly to a Fire Alarm Control FACP or provide a synchronized strobe appliance when used in conjunction with an FACP that incorporates the Cooper Whee sync protocol a Dual Sync Module DSM or the Wheelock Power Supply calculating the total currents use Table 2 to determine the highest value of RMS current for an individual appliance then multiply these by the total number of appliances Be sure to add the currents for any other appliances including audible signaling appliances powered by same source and to include any required safety factors 2 LSTC3 B Current Draw Amps 33.0 Volts Candela Settings cd Candela will determine the current draw of the product These notification appliances are UL Listed as They are intended to be used with Fire Alarm Control Panels notification circuits are UL Listed as Refer to the FACP instructions or the Cooper Wheelock Strobe Compat Data Sheet PN P85328 for special application and strobe synchronization compatibility These appliances were tested to the regulated voltage limits of 16.0 33.0 Volts for 24 volt models and either filtered dc or unfiltered for the 24 volt range voltage Do not apply voltage outside of this range Check the minimum and maximum output of the power supply and standby battery and subtract the voltage drop from the circuit resistance to determine the applied voltage to the strobes The maximum wire impedance between strobes shall not exceed 35 Strobes are not designed to be used on coded systems in which the applied voltage is cycled on and off Make sure that the total rms current required by all appliances that are connected to the system primary and secondary power Notification Appliance Circuit NAC DSM sync module or Wheelock power supplies does not exceed the power sources capacity or the current ratings of any fuses on the circuits to which these appliances are wired Overloading power sources or fuse ratings could result in loss of power and failure to alert occupants during an emergency which could result in property and serious injury or death to you and or others AND MOUNTING BASE All strobe appliances have in out wiring terminals that accept two 12 to 18 American Wire Gauge AWG wires at each screw Strip leads 3 8 inches and connect to screw terminals Break all in out wire runs on supervised circuits to ensure integrity of circuit supervision as shown in Figure 2 The polarity shown in wiring diagrams is for the operation of the appliances The polarity is reversed by the FACP during supervision Figure 1 LED Strobe Wiring 2 Wire Connection Wiring method shall be in accordance with CSA C22.1 Canadian Electrical Code Part 1 Safety Standard for Electrical Section 32 Do not fully back out terminal screws AND MOUNTING SETTINGS The LSTC3 B are factory set to 15 candela Candela factory settings are shown in Figure 3 Figure 3 Candela Selector Check that the installed product will have sufficient clearance and wiring room prior to installing backboxes and conduit if sheathed multiconductor cable or 3 4 inch conduit fittings are used the limits shown for the mounting option comply with the National Electrical Code NEC Cooper Wheelock recommends use the largest backbox option available and the use of approved stranded field wires whenever possible to provide additional wiring for easy installation and minimum stress on the product from wiring Do not over tighten mounting screws Excessive torque can distort the base and may affect operation When using power tools to screw down the mounting plate to the electrical backbox ensure the torque is set to the lowest available OPTIONS Connect field wiring to contacts on back of device Dress wires back into backbox Install device as shown in Figure 4 Figure 5 or Figure 6 4 square backbox or octal with the screws provided Snap beauty cover over device To remove the appliance insert a small flat bladed screwdriver into the side opening as shown in Figure 7 Then pry off the cover with the screw driver and remove mounting screws Figure 4 Ceiling Strobe with LSPKBBC Surface Mounting Box Figure 5 Strobe Installation with 4 Backbox Branchport Ave Long Branch N J 07740 800 631 2148 www coopernotification comPN P85582 002ACopyright 2017 Cooper Wheelock Inc dba Cooper Notificationfirealarmresources com Figure 6 Strobe Installation with Octal Backbox Figure 7 Removing a Strobe Cover Backbox must be recessed flush with the ceiling surface Remove the lens protector tape before replacing the appliance cover grille For surface mounting options please use the LSPKBB C accessory products DO NOT PAINT THIS DEVICE When installing strobes in an open office or other areas containing partitions or other viewing obstructions special should be given to the location of the strobes so that their operating effect can be seen by all intended viewers with intensity number and type of strobes being sufficient to make sure that the intended viewer is alerted by proper illumination of the viewer orientation A small possibility exists that the use of multiple strobes within a person field of view under certain circumstances induce a photo sensitive response in persons with epilepsy Strobe reflections in a glass or mirrored surface might also such a response To minimize this possible hazard Cooper Notification strongly recommends that the strobes installed not present a composite flash rate in the field of view which exceeds five 5 hz at the operating voltage of the strobes Wheelock also strongly recommends that the intensity and composite flash rate of installed strobes comply with levels by applicable laws standards regulations codes and guidelines NFPA 72 ANSI 117.1 conform to ADAAG Equivalent Facilitation Guidelines in using fewer higher intensity strobes within the same area Check the installation instructions of the manufacturers of other equipment used in the system for any guidelines or restrictions wiring and or locating Notification Appliance Circuits NAC and notification appliances Some system communication circuits and or circuits for example may require special precautions to assure electrical noise immunity e g audio crosstalk Th