Wheelock MIZ horns install sheet P84408

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | wheelock-miz-horns-install-sheet-p84408-5920681743.pdf |

|---|---|

| Type | |

| Size | 873.56 KB |

| Downloads |

Text Preview

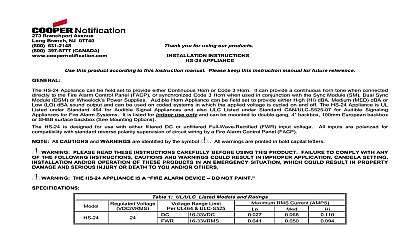

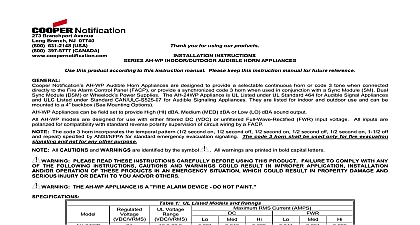

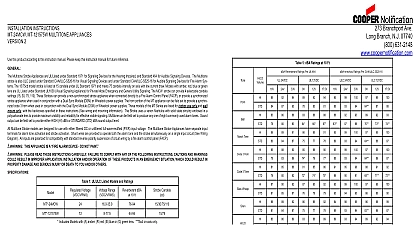

INSTALLATION INSTRUCTIONS HORNS this product according to this instruction manual Please keep this instruction manual for future reference MIZ Mini Horns are designed to produce high sound output with minimal current require They are UL Listed under UL 464 Standard for Audible Signal Appliances and ULC Listed Standard CAN ULC S525 07 Standard for Audible Signal Appliances For Fire Alarm Systems All are polarized for compatibility with standard reverse polarity supervision of circuit wiring by a Fire Control Panel FACP MIZ Mini Horns are recommended for alarm signaling for individual rooms apartments motels hotels and offices They mount to standard backboxes to reduce the cost of All models are listed for indoor use with the backboxes specified in these instructions See Options provide a selectable Continuous or Code 3 horn tone when connected directly to a Fire Alarm Panel FACP They can also provide a synchronized Code 3 horn tone when used in conjunc with a Sync Module SM Dual Sync Module DSM or Cooper Wheelock Power Supplies Horns can be used on coded systems where the applied voltage is cycled on and off Please read these instructions carefully Failure to comply with any of the following cautions and warnings could result in improper application installation and or op of these products in an emergency situation which could result in property damage and injury or death to you and or others The MIZ appliance is a fire alarm device DO NOT PAINT 1 UL and ULC Listed Models and Ranges UL 464 Range Limit Range Per 2 UL ULC dBA Sound Output Per UL 464 10 Ft dBA Per CAN ULC 10 Ft Horn 3 Horn 90 3 U ULC Current Ratings AMPS RMS Current 4 ULC Directional Characteristics degrees right 90 degrees left degrees right 90 degrees left degrees up 85 degrees down degrees up 90 degrees down Anechoic dBA is measured in anechoic chamber with fast meter response Reverberant dBA is rated per UL 464 Standard for Audible Signal Appliances For UL ULC applications these appliances were tested to the operating voltage limits 16.0 33.0 Volts for 24.0VDC models using filtered DC or unfiltered full wave rectified FWR not apply 80 and 110 of these voltage values for system operation Verify the minimum and maximum output of the power supply and standby battery and sub the voltage drop from the circuit wiring resistance to determine the applied voltage to the strobes Ensure the current required by all appliances that are connected to the system pri and secondary power sources NAC circuits SM DSM sync modules or Cooper Wheelock supplies do not exceed the power sources rated capacity or the current ratings of any on the circuits to which these appliances are wired Overloading power sources or exceed fuse ratings could result in loss of power and failure to alert occupants during an emergency could result in property damage and serious injury or death to you and or others calculating the total current use Table 3 to determine the highest value of RMS Current for an horn across the expected operating voltage range of the device Then multiply this value the total number of devices Be sure to add the current for any other devices powered by the same and include any required safety factors INFORMATION PRECEDING OR FIRE ALARM PANEL FACP NEXT APPLIANCE END OF LINE EOLR 1 2 Appliances have in out wiring terminals that accept two 12 to 18 American Wire Gauge AWG at each screw terminal Strip leads 3 8 of an inch and connect to screw terminals Break all in out wire runs on supervised circuits to ensure the integrity of circuit supervision shown Figure 1 The polarity shown in the wiring diagrams is for the operation of the appliances The is reversed by the FACP during supervision Wiring method shall be in accordance with CSA C22.1 Canadian Electrical Code Part 1 Safety for Electrical Installations Section 32 Branchport Ave Long Branch N J 07740 800 631 2148 www coopernotification comPN P84408MCopyright 2012 Cooper Wheelock Inc dba Cooper Notificationfirealarmresources com 5 Temporal Code 3 Non Temporal Continuous Jumper Settings NAC 3 3 3 OPTIONS The following figures show the maximum number of field wires conductors that can enter the used with each mounting option If these limits are exceeded there may be insufficient space in backbox to accommodate the field wires and stresses from the wires could damage the product the limits shown for each mounting option comply with the National Electrical Code NEC Notification recommends use of the largest backbox option shown and the use of approved field wires whenever possible to provide additional wiring room for easy installation and mini stress on the product from wiring with SM DSM Code 3 Requires use of SM DSM or Cooper Wheelock Power Supplies in Wheelock Sync mode MOUNTING MOUNTING 3 Temporal Code 3 Non Temporal Continuous Select Temporal shorted Non Temporal open is shipped from factory with Temporal Code 3 selected jumper to right Installer can select Non Continuous audible signal by moving the factory installed jumper to the left one position The is placed only on the left pin leaving the circuit open to select Continuous Detach Beauty Plugs rear of the grille before installing unit PROCEDURES 4 this mounting procedure to position the field wires in the backbox so that they use minimum space produce minimum stress on the product This is especially important for stiff heavy gauge wires wires with thick insulation or sheathing Connect the 2 field wires to each screw terminal in out wiring and dress the 2 wires through the as shown in Figure 4 polarity must be observed Gently push the 4 field wires into the backbox by hand and screw the unit to the backbox X 3 1 2 BACKBOX NUMBER OF CONDUCTORS 18 AWG 16 AWG 14 AWG 12 X 1 3 4 WIREMOLD NUMBER OF CONDUCTORS 18 AWG 16 AWG 14 AWG 12 NOTES Verify the installed product has sufficient clearance and wiring room prior to installing back and conduit especially if sheathed multi conductor cable or 3 4 inch conduit fittings are used Mounting hardware for each mounting option is supplied When terminating field wires do not use more lead length than required Excess lead length could in insufficient wiring space for the signaling appliance Use care and proper techniques to position the field wires in the backbox so they use minimum and produce minimum stress on the product This is especially important for stiff heavy wires and wires with thick insulation or sheathing Do not pass additional wires used for other than the signaling appliance through the backbox additional wires could result in insufficient wiring space for the signaling appliance Place Beauty Plugs over screw heads after installation using the mounting hardware supplied All models are UL Listed for indoor use with a temperature range of 32 to 120 0 to 49 maximum humidity of 93 RH this appliance is required to produce a distinctive three pulse Temporal Pattern Fire Alarm Evacuation for total evacuation in accordance with NFPA 72 1999 Edition the appliance must be used with Fire Alarm Control unit that can generate the temporal pattern signal Refer to manufacturer installa manual for details Verify the installation instructions of the manufacturers of other equipment used in the sys for any guidelines or restrictions on wiring and or locating Notification Appliance Circuits NAC and appliances Some system communication circuits and or audio circuits for example may special precautions to ensure electrical noise immunity e g audio crosstalk MATERIAL EXTRAPOLATED FROM THIS DOCUMENT OR FROM COOPER NOTIFICATION OR OTHER DOCUMENTS DESCRIBING THE PRODUCT FOR USE IN PROMOTIONAL OR CLAIMS OR FOR ANY OTHER USE INCLUDING DESCRIPT