Wheelock STH-15S speaker install sheet P82697

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | wheelock-sth-15s-speaker-install-sheet-p82697-0621397548.pdf |

|---|---|

| Type | |

| Size | 712.54 KB |

| Downloads |

Text Preview

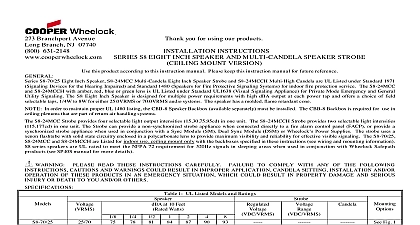

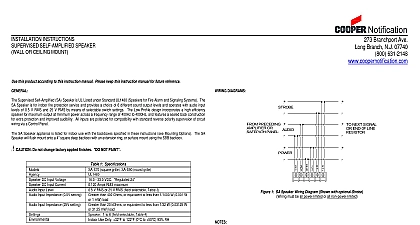

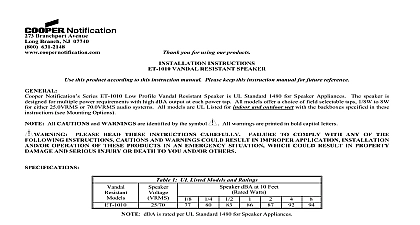

Wheelock Branchport Avenue Branch N J 07740 631 2148 you for using our products INSTRUCTIONS HORN SPEAKER WITH MULTI TAP TRANSFORMER CAPACITOR FOR DC LINE SUPERVISION this product according to this instruction manual Please keep this instruction manual for future reference Grey Listed under CAN ULC S541 2016 for Speaker Appliances Listed under CAN ULC S541 2016 for Speaker Appliances STH 15S ULC and STH 15SR ULC Horn Speakers are Listed for indoor fire protection service under Standard ULC Speakers for Fire Alarm and Signaling Systems The STH 15 is designed for multiple power requirements with high output at each power tap STH 15 models offer a choice of field selectable taps 0.48 to 15 Watts for use with either or 70VRMS audio systems The STH 15 design incorporates a compression driver mounted on a double re entrant for maximum output at minimum power across a frequency range of 400 to 4,000Hz The STH 15 input is compatible with DC supervision of circuit wiring by a Fire Alarm Control Panel FACP A capacitor is internally wired in series with the impedance matching transformer for this purpose Do not change factory applied finishes NOT PAINT Ne pas modifiez les finitions appliqu en usine PAS PEINTURER PLEASE READ THESE INSTRUCTIONS CAREFULLY FAILURE TO COMPLY WITH ANY OF THE INSTRUCTIONS COULD RESULT IN IMPROPER APPLICATION INSTALLATION AND OR OPERATION OF PRODUCTS IN AN EMERGENCY SITUATION WHICH COULD RESULT IN PROPERTY DAMAGE SERIOUS OR DEATH TO YOU AND OR OTHERS 1 Wattage Selector Switch Settings and dBA 0.9W 1.8W 3.8W 7.5W Used Used 93 96 96 99 Used Used Used Used 7.0W Used Used 90 90 93 99 Handling Capacity RMS 15W Dispersion 70 Degrees Voltage Line 25V or 70V Response 400 4,000Hz Full Rated Output Level Peak 120dB at 15W 1 Meter 7 7 8W X 8 3 4H X 9 5 16L Do not place switch in settings marked not used Failure to comply with these restrictions may cause damage components and will void the warranty 2021 Cooper Wheelock Inc dba Cooper Notification STH 15 Horn Speaker is not intended for use in hazardous locations INFORMATION is a slotted shaft underneath the cable entrance interface adapter which operates a 7 position selector switch Remove interface adapter and set the switch for the desired wattage at the specified speaker line voltage 25V or 70V Adjust the by turning the slotted shaft until the end of the slot which is opposite the flat on the shaft points to the desired number wattage provided at each selector number is shown on the decal affixed to the rear of the housing INFORMATION STH 15 Horn Speaker may be wall mounted by simply using the holes in the swivel base to locate and drill mounting holes the base to the surface with appropriate hardware Slots are also provided in the base for banding straps to allow to beams poles and girders The mounting base is also fully adjustable in both the vertical and horizontal planes See 1 1 OVERHEAD VIEW OF MOUNTING BASE WITHOUT HORN NUT FOR ROTATION AND ADJUSTMENTS ROTATES 360 DEGREES SLOT 2 HOLE 3 ARM SWIVELS Loosening the wing nut will allow for both pitch and rotation of the unit When adjusting horn position be careful not to lose adjusting hardware interface adapter mounted to the horn permits conduit connection The interface adapter is threaded for standard 1 2 and will accommodate BX cable flexible or rigid conduit and matching connectors The interface adapter is shown in 2 below 2 ADAPTER J 1 of 2 installations shall be in accordance with In Canada CSA C22.1 Canadian Electrical Code Part I Safety Standard for Electrical Installations Section 32 and the Standard for the Installation of Fire Alarm Systems CAN ULC S524 In the United States the National Electrical Code NFPA 70 and the National Fire Alarm and Signaling Code NFPA 72 INFORMATION 3 Wiring Diagram Break IN OUT wire runs to provide for supervision of ALL connections NOTES Horn Speakers are ULC Listed for indoor outdoor use with a temperature range of 40 to 151 40 to and maximum humidity of 95 RH blocking capacitor for DC supervision of audio lines by the FACP is factory wired in series with the speaker input bass energy can damage horn voice coils especially at high power levels To avoid possible damage an with a bass roll off filter horn protect circuit should be used operate audio amplifiers and speakers within their specified ratings Excessive input may distort sound quality may damage audio equipment Do not exceed 130 of speaker input voltage Improper input voltage can speaker If distortion is heard check for clipping of the audio appliance with an oscilloscope and reduce the input level or gain level to eliminate any clipping not over tighten screws or terminals Excessive torque may affect operation When using power tools ensure the is set to the lowest setting available Check the installation instructions of the manufacturers of other equipment used in the system for any guidelines restrictions on wiring and or locating Notification Appliance Circuits NAC and notification appliances Some system circuits and or audio circuits for example may require special precautions to assure electrical noise immunity audio crosstalk MATERIAL EXTRAPOLATED FROM THIS DOCUMENT OR FROM COOPER WHEELOCK MANUALS OR OTHER DESCRIBING THE PRODUCT FOR USE IN PROMOTIONAL OR ADVERTISING CLAIMS OR FOR ANY USE INCLUDING DESCRIPTION OF THE PRODUCT APPLICATION OPERATION INSTALLATION AND IS USED AT THE SOLE RISK OF THE USER AND COOPER WHEELOCK WILL NOT HAVE ANY LIABILITY FOR USE READ SEPARATE GENERAL INFORMATION SHEET FOR INFORMATION ON THE PLACEMENT INSTALLATION FINAL CHECKOUT AND PERIODIC TESTING OF NOTIFICATION APPLIANCES Warranty Wheelock products must be used within their published specifications and must be PROPERLY specified applied operated maintained and operationally tested in accordance with these instructions at the time of installation and at twice a year or more often and in accordance with local state and federal codes regulations and laws Specification installation operation maintenance and testing must be performed by qualified personnel for proper operation in with all of the latest National Fire Protection Association NFPA Underwriters Laboratories UL Underwriters of Canada ULC National Electrical Code NEC Occupational Safety and Health Administration OSHA local county province district federal and other applicable building and fire standards guidelines regulations laws and codes but not limited to all appendices and amendments and the requirements of the local authority having jurisdiction Cooper Wheelock products when properly specified applied installed operated maintained and operationally tested as above are warranted against mechanical and electrical defects for a period of three years from date of manufacture as by date code Correction of defects by repair or replacement shall be at Cooper Wheelock sole discretion and constitute fulfillment of all obligations under this warranty THE FOREGOING LIMITED WARRANTY SHALL TERMINATE IN THE EVENT ANY PART NOT FURNISHED BY COOPER WHEELOCK IS INSTALLED IN THE THE FOREGOING LIMITED WARRANTY SPECIFICALLY EXCLUDES ANY SOFTWARE REQUIRED FOR THE OF OR INCLUDED IN A PRODUCT COOPER WHEELOCK MAKES NO REPRESENTATION OR WARRANTY ANY OTHER KIND EXPRESS IMPLIED OR STATUTORY WHETHER AS TO MERCHANTABILITY FITNESS FOR A PURPOSE OR ANY OTHER MATTER ARE SOLELY RESPONSIBLE FOR DETERMINING WHETHER A PRODUCT IS SUITABLE FOR THE USER OR WHETHER IT WILL ACHIEVE THE USER INTENDED RESULTS THE