Ademco - 5819 Shock Processor Transmitter

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | ademco-5819-shock-processor-transmitter-0739542186.pdf |

|---|---|

| Type | |

| Size | 960.63 KB |

| Downloads |

Text Preview

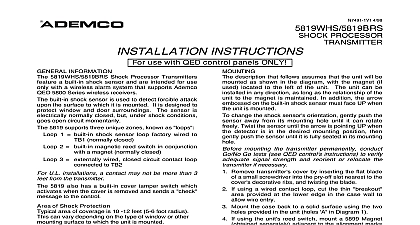

N7491V2 2 96 5819 PROCESSOR INSTRUCTIONS A 2 TEXT PRY 0FF POINT 1 TIME Most Sensitive Least Sensitive 20ms MAGNET MARKS ON AND GUIDE MTG PLATE B LOOP 3 J4 J3 J2 J1 SENSOR LOOP 1 2 Most Sensitive Least Sensitive TAB WINDOW 2 2 SWITCHES Detail PINS Detail 1 TERMINALS Detail 3 TERMINALS Detail FOR ACCESS 1 MOUNTING PLATE INFORMATION No 5819 Shock Processor Transmitter connects to type shock detectors which are mounted externally the transmitter case detector not supplied and is for use only with a wireless alarm system that 5800 Series wireless receivers No 5819 has three unique zones The first is for a normally closed shock sensor loop TB1 the is for a closed contact loop using the unit built in reed switch in conjunction with a magnet and third is for a wired closed circuit contact loop TB2 U L installations a contact may not be more than 3 from the transmitter No 5819 has a built in cover tamper switch which when the cover is removed proper orientation of the unit in relation to the plate loop wiring DIP switch adjustment jumper and or magnet read all of this section before the unit description that follows assumes that the unit will be as shown in the diagrams with the magnet if located to the left of the unit The unit can be in any direction as long as the relationship of the to its mounting plate and if used magnet is two holes are provided in the unit that would mounting directly to a surface holes in Diagram it is recommended that the mounting plate be used as below for ease in removing the unit for should it become necessary mounting the transmitter permanently conduct Go tests see control instructions to verify signal strength and reorient or relocate the if necessary 2 No 5819 SHOWN WITH COVER REMOVED Remove transmitter cover by inserting the flat blade a small screwdriver into the pry off slot nearest to cover decorative ribs and twisting the blade Disengage the supplied mounting plate from the unit inserting the blade of a small screwdriver into the tab release window see Diagram 2 and it against the locking tab see Diagram 1 sliding the plate downward along the case back a shock processor or wired contact loop is to be with concealed wiring feed the wires through concealed wiring entry hole at one corner of the For surface wiring entry a thin breakout area provided in the case wall the mounting plate with its case holding posts up in this example in the location selected described in the control unit installation Use the flat head screws supplied Attach the case back to the mounting plate by sliding keyhole slots in the case back down onto the plate case holding posts The locking tab click as the case back locks in place the unit REED SWITCH is to be used mount a No Magnet obtained separately adjacent to the marks on the case and the mounting plate strip see Diagram 2 Set response time using the DIP switches use the tip a pen pencil SW1 sets a response time of 1ms SW5 sets a response time of 20ms For a time of 0.5ms set all DIP switches to OFF Table 1 Set the pulse count jumper see Table 2 The pulse is reset 3 seconds after the first pulse detected is an LED on the PCB which flashes rapidly on Make the device highly sensitive for the of learning the shock sensor loop TB1 the system turn SW 1 on and put jumper on After the device has been learned adjust as described in steps 7 and 8 above Connections the battery still not inserted connect the shock loop if used to the unit loop TB1 terminals Detail B The contact loops must use closed devices TB2 can be used for normally closed If the contact loops are not used no connection needed across their terminals the Transmitter Serial Number No 5819 Shock Processor has its own unique number permanently assigned during Each input of the transmitter also has a loop number that must be input to the control during installation Assign each to an individual and designate the Input Type as RF Supervised serial number can be input by one of the following Learned by the control during manual zone Entered through the keypad at the Input or Transmit Now prompt during manual zone Entered through VLINK Downloading Software and to the control using either method 2 or 3 be sure to include the loop of each input see diagram learn the 5819 transmitter serial number at control panel do the following Enter 56 mode on Vista 20 panels and below or Zone Programming mode on Vista 40 panels above Enter the Response Type and other zone information the first zone pressing to advance from to prompt At the Input Type prompt enter 3 for RF RF and press At the Input S N or Transmit Now prompt fault restore the loop input being learned keypad will to confirm Wait approximately 6 seconds and then fault and the loop input again keypad should beep to confirm This input should now be learned will display one of the following screens PROG AS RF 1 3078 1 ZT RC In L 03 00 RF 1 the display on the left below appears press to the zone summary On this screen display there is not an N or a under the L this indicate the loop is not learned Press to advance to the next zone and repeat above for the remaining loop inputs zones are using INSTALLATION REPLACEMENT Remove the transmitter cover as described in Step 1 Observe correct polarity and insert the battery into the battery holder see Diagram 2 Replace the cover engage the hooks along one and snap shut not bend the antenna Replace with 3V Lithium battery only CR123A Duracell DL123A Sanyo or ADEMCO 466 CAUTION Risk of fire explosion and Do not recharge disassemble heat above F 100 cid 176 C or incinerate Dispose of used promptly Keep away from children DIMENSIONS H x 1.5 W x 1 D THE INSTALLER maintenance and inspection at least by the installer and frequent testing by the are vital to continuous satisfactory operation of alarm system The installer should assume the of developing and offering a regular program to the user as well as the user with the proper operation and of the alarm system and its component Recommendations must be included for a program of frequent testing at least weekly insure the system operation at all times TO THE INSTALLATION INSTRUCTIONS THE RECEIVER CONTROL WITH WHICH THIS IS USED FOR WARRANTY INFORMATION FOR DETAILS REGARDING THE OF THE ENTIRE ALARM SYSTEM DE V I CE MANUFACTURI NG CO D I VI SI O N O F PI T T W AY C O R PO R AT I O N 6 5 E i l e e n Wa y S y os s e t Ne w Y or k 1 1 7 9 1 opy r i ght 1996 Pi t t w ay C or por at i on