Autocall Modules A4090-9002 IDNet Relay IAM Installation Manual

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | autocall-modules-a4090-9002-idnet-relay-iam-installation-manual-5934608217.pdf |

|---|---|

| Type | |

| Size | 1.00 MB |

| Downloads |

Text Preview

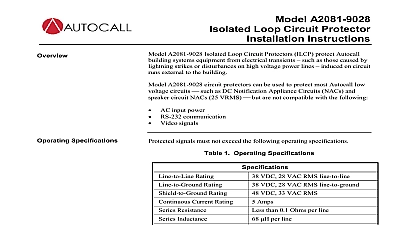

A4090 9002 IDNet Relay IAM Installation Instructions warnings and regulatory information AND SAVE THESE INSTRUCTIONS Follow the instructions in this installation manual These instructions must be followed to avoid damage to product and associated equipment Product operation and reliability depend upon proper installation NOT INSTALL ANY AUTOCALL PRODUCT THAT APPEARS DAMAGED Upon unpacking your Autocall product inspect the of the carton for shipping damage If damage is apparent immediately file a claim with the carrier and notify an authorized product supplier HAZARD Disconnect electrical field power when making any internal adjustments or repairs All repairs should be by a representative or an authorized agent of your local Autocall product supplier HAZARD Static electricity can damage components Handle as follows Ground yourself before opening or installing components Prior to installation keep components wrapped in anti static material at all times A4090 9002 Relay Individual Addressable Module IAM provides the 4010ES and 4100ES Fire Alarm Control Unit FACU control of one dry form C set Normally Open Normally Closed and Common IAM reports its current state back to the FACU for confirmation of operation through the IDNet channel The IDNet channel provides the link between the IAM and the FACU and powers the entire Relay IAM circuitry IAM installation consists of the following Setting the Relay IAMs address Making electrical connections to the Relay IAM Mechanically installing the Relay IAM 4 IAM Back Box Installation When wiring the Relay IAM provide a minimum of 0.25 in spacing between IDNet wiring and contact wiring Use separate conduit entries if contacts are switching non power limited power sources When both power limited and non power limited sources are present use type FPLR or FPLP power limited cable for power limited circuits and surface covers with a light pipe are available to be ordered separetly The covers with light pipe allow viewing of the LED without taking the cover off Installation of the A4090 9801 semi flush cover and A4090 9802 surface cover are detailed publication A4090 IDNet Semi Flush Surface Covers and IAM Bracket Installation Instructions 574 796AC 2019 Johnson Controls All rights reserved All specifications and other information shown were current as of document revision and are subject to change without notice Additional listings may be applicable contact your local Autocall supplier for the latest status Listings and approvals under Tyco Fire Security GmbH and the product names listed in this material are marks and or registered marks Unauthorized use is strictly prohibited NFPA 72 and National Alarm Code are registered trademarks of the National Fire Protection Association NFPA Rev J Rev J The LED flashes approximately once every three seconds to indicate valid communications with the FACU 1 IAM Installation IDNet Relay IAM Installation Instructions IDNet Relay IAM Installation Instructions the Relay IAMs Address Relay IAM has a unique address 1 through 250 The address of the IAM is set through an eight position DIP switch Figure 2 DIP switch position is the least significant bit LSB and position 8 is the most significant bit MSB Set the IAMs address using Figure 2 as reference Use a small or pen to set the switches The device address for the Relay IAM should be written on the re sealable label information provides an aid in troubleshooting the system DIP switch in position 1 is ON while DIP switch in position 0 is OFF 3 IAM Connections When connecting two wires to one terminal position one wire on each side of the terminal screw Maximum allowable run from the FACU to farthest device cannot exceed 2500 ft Refer to field wiring diagrams for further information on wiring Relay IAMs Refer to the FACU label appropriate revision of the field wiring diagram to be used IDNet wiring is supervised and power limited wiring to relay contacts is unsupervised use 14 AWG or wiring that meets local code requirement Relay contact wiring is only if switching power is provided by the FACU or a UL listed power limited power supply for fire protective signaling systems loads must be suppressed with a suitable suppression device If switching 120 VAC the power source to the contacts should be fused by the user with a 1 Amp 250 V quick blow fuse UL listed to Guide JDYX Littlefuse AGC1 or equivalent The operation of relay is programmable wiring shall be installed in accordance with the requirements of the National Fire Alarm and Signaling Code NFPA 72 Installing the Relay IAM the Relay IAM into a UL Listed 4 inch back box not supplied using Figure 4 as a reference Mount the IAM to the back box as follows the two screws on the square back box Mount the IAM to the back box using the teardrop holes on the mounting bracket the IAM to the back box using the two 8 32 panhead screws 2 IAM Address Chart and 4010ES FACU IDNet Channel the Relay IAM to the panel using the ES Panel Programmer Manual 574 849AC Electrical Connections to the Relay IAM and output signals connect to the Relay IAM through the terminals 1 8 as illustrated in Figure 1 Terminal connections for the IAM are illustrated Figure 3 Do not loop wire under terminals Break wire runs to provide supervision 2 Rev J 3 Rev J