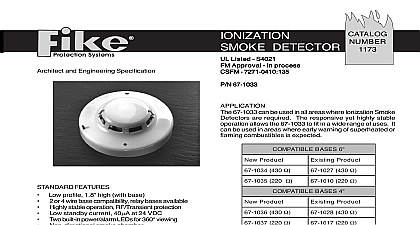

Fike P 1 17 01 Ionization Smoke Detector

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | fike-p-1-17-01-ionization-smoke-detector-6432809175.pdf |

|---|---|

| Type | |

| Size | 655.90 KB |

| Downloads |

Text Preview

IONIZATION SMOKE DETECTOR 67 1033 can be used in all areas where Ionization Smoke Detectors are The responsive yet highly stable operation allows the 67 1033 to in a wide range of uses It can be used in areas where early warning of or flaming combustibles is expected Bases 6 Bases 4 Product 430 220 Product 430 220 Product 430 220 Product 430 220 profile 1.8 high with base or 4 wire base compatibility relay bases available Highly stable operation RF Transient protection Non directional smoke chamber standby current 40mA at 24 VDC built in power alarm LEDs for 360 viewing 67 1033 Listed S4021 Approval 3010873 7271 0410 135 resistant security locking feature magnetic detector sensitivity test feature Meets NFPA 72 Chapter 7 Inspection Testing and Maintenance with Fike 63 1024 photoelectric detector compatible with Fike 63 1008 and 67 1016 smoke detector 67 1033 ionization smoke detector utilizes two bi colored LEDs for status indication purposes In a normal standby the LEDs flash green approximately once each second When the detector senses smoke and goes into alarm status LEDs will latch on red single radioactive source of Americium 241 ionizes two chambers within the detector a reference chamber and the sensing chamber The air is ionized by this source and a small DC current flows between the electrodes of each Smoke can freely enter the sensing chamber while the inner chamber is virtually sealed to smoke Smoke the sensing chamber causes a reduction in the DC current flow the voltage imbalance between the two chambers proportional to the smoke density When the voltage differences become great enough it causes the detector to go into The two chamber design is utilized to compensate for changes in atmospheric and environmental conditions Source Voltage Voltage Voltage Current Current Current Temperature 0.5mCi 30.0 VDC 33.0 VDC VDC 24 VDC max 24 VDC max 24 VDC to 120 to 49 Case Material PC ABS Blend Test Feature Magnetically activated reed switch test S 10th Street P O Box 610 Blue Springs Missouri 64013 0610 U S A 816 229 3405 816 229 4615 www fike com No P 1.17.01 2 SPECIFICATIONS contractor shall furnish and install where indicated on the plans the 67 1033 ionization smoke detectors The detector head and twist lock base shall be UL listed compatible with a UL listed fire alarm panel base shall permit direct interchange with 63 1024 photoelectric type smoke detector the 63 1025 combination detector and or 60 1029 or 60 1030 fixed temperature rate of rise heat detectors The base shall be a compatible twistlock base In the event of partial or complete retrofit the 67 1033 may be used in conjunction or as a replacement for Fike detectors 63 1007 63 1016 and the 67 1016 smoke detector shall have two flashing status LEDs for visual supervision When the detector is in standby condi the LEDs will flash Green When the detector is actuated the flashing LEDs will latch on Red The detector may be by actuating the control panel reset switch sensitivity of the detector shall be capable of being verified It shall be possible to perform a functional test of the without the need of generating smoke The test method shall simulate effects of products of combustion in chamber to ensure testing of the detector electronics facilitate installation the detector shall be non polarized Voltage and RF transient suppression techniques shall be to minimize false alarm potential Auxiliary SPDT relays shall be installed where indicated vandal resistant security locking feature shall be used in those areas as indicated on the drawing The locking feature be field removable when not required SMOKE DETECTOR SENSITIVITY TEST FEATURE Procedure With detector wired to appropriate initiating circuit or current limited power source and with normal applied power a magnet as shown in Figure 1 Wait at least six seconds Detector SHOULD NOT alarm and LED should not light Place magnet on detector as shown in Figure 2 opposite side Wait at least six seconds Detector SHOULD alarm detector does alarm when magnet is positioned as in Figure 1 or does not produce an alarm when magnet is as in Figure 2 detector is not within specified sensitivity limits and may require service Conduct testing only under Normal Standby conditions Abnormal or Low Power conditions may affect Always reset power prior to testing of next unit 1 2 Fike Corporation All Rights Reserved No P 1.17.01 2 July 2005 Specifications are subject to change without notice