Fike Vesda LaserPLUS V 1 01 01

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | fike-vesda-laserplus-v-1-01-01-4182560937.pdf |

|---|---|

| Type | |

| Size | 824.99 KB |

| Downloads |

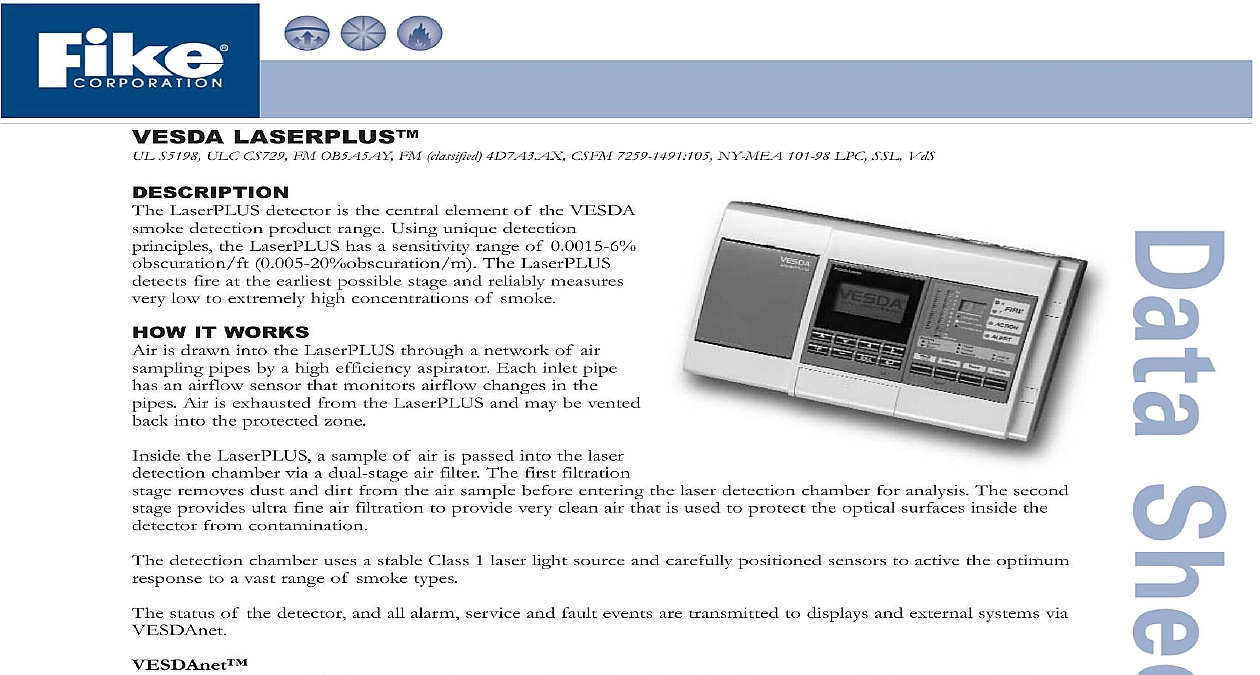

Text Preview

VESDA LASERPLUS S5198 ULC CS729 FM OB5A5AY FM classified 4D7A3 AX CSFM 7259 1491 105 NY MEA 101 98 LPC SSL VdS LaserPLUS detector is the central element of the VESDA detection product range Using unique detection the LaserPLUS has a sensitivity range of 0.0015 6 0.005 20 obscuration m The LaserPLUS fire at the earliest possible stage and reliably measures low to extremely high concentrations of smoke IT WORKS is drawn into the LaserPLUS through a network of air pipes by a high efficiency aspirator Each inlet pipe an airflow sensor that monitors airflow changes in the Air is exhausted from the LaserPLUS and may be vented into the protected zone the LaserPLUS a sample of air is passed into the laser chamber via a dual stage air filter The first filtration removes dust and dirt from the air sample before entering the laser detection chamber for analysis The second provides ultra fine air filtration to provide very clean air that is used to protect the optical surfaces inside the from contamination detection chamber uses a stable Class 1 laser light source and carefully positioned sensors to active the optimum to a vast range of smoke types status of the detector and all alarm service and fault events are transmitted to displays and external systems via detectors and devices communicate across VESDAnet the fault tolerant communications protocol The loop provides a robust bi directional communication network between devices even allowing continued during single point wiring failures It also allows for system programming from a single location and forms basis of the modular nature of the VESDA system LaserPLUS technology employs unique software tools to ensure optimum operation in many differing AutoLearn monitors the ambient environment and sets the most appropriate alarm thresholds Alert Fire1 Fire2 during the commissioning process to allow the earliest possible warning of a potential fire with no nuisance alarms that employ air handling systems may be affected by pollution external to the controlled environment air make up is added Referencing by VESDA ensures that external pollution does not interfere with the smoke level being detected in the protected environment The system can safely compensate for this transient and allow continued operation free from nuisance alarms S 10th Street P O Box 610 Blue Springs Missouri 64013 0610 U S A 816 229 3405 816 229 4615 www fike com No V 1.01.01 Based Smoke Wide Sensitivity Range Detection High Efficiency Aspirator Dual Stage Air Filter Configurable Alarm Levels Inlet Pipes Supervisor per Sampling Pipe Voltage Consumption 24VDC to Replace Air Filter Programmable Relays Log Modular Design Mounting Option WHD Conditions Network Size Relays Rating Access Termination Range Threshold Setting Range Features to 30VDC Display or Programmer 3000rpm 4200rpm Alarm Alarm x 8.9in x 4.9in x 225mm x 125mm 4.0kg including Display and Programmer modules Ambient 32 to 103 90 to 39 Air 4 to 140 20 to 60 10 95 RH non condensing consult your Vision Systems office for operation outside parameters area of coverage 20,000 sq ft pipe length in accordance with Computer Design Tool and NFPA standards Diameter 1in 25mm Diameter 9 16in 7 8in 15 21mm Relays Contacts rated 2A 30VDC NO NC Contacts in 8x25 mm knockouts in various positions terminals 30 12 AWG 0.2 2.5sq mm to 6 obs ft 0.005 to 20 obs m 0.0015 0.6218 obs ft 0.005 1.990 obs m 0.0031 0.6234 obs ft 0.010 1.995 obs m 1 0.0046 0.625 obs ft 0.015 2.00 obs m 2 0.0062 6.25 obs ft 0.020 20.00 obs m to 4 obs ft 12 obs m in UL mode Log Up to 18,000 events stores on FIFO basis Minimum 15 minutes maximum 15 days minimum period 1 day During AutoLearn are NOT changed from pre set values Compensation for external ambient conditions Alarm Levels Alert Action Fire 1 Fire 2 Fault Warning Levels Maintenance and Major fault Programmable Relays 7 Aids Filter Flow monitoring reporting via VESDAnet or Event Log MOUNTING BOX TERMINATION CARD SURFACE MOUNTING BRACKET INFORMATION VLP 000 VLP 400 VLP 002 VLP 010 VLP 012 Detector only Detector with two LEDs Detector with display Detector with programmer Detector with display and programmer Fike Corporation All Rights Reserved No V 1.01.01 July 2005 Specifications are subject to change without notice Systems manufacturers VESDA and ADPRO products In accordance with its policy of continuing to product and system improvement Vision reserves the right change engineering design or specifications without incurring obligation and without further notice VESDA is a registered trademark of Vision Systems ASPIRE AutoLearn VSM VESDAnet and VESDAcad are trademarks of VisionSystems