Honeywell Thermostat V8043 User Manual

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | honeywell-thermostat-v8043-user-manual-4532180796.pdf |

|---|---|

| Type | |

| Size | 700.91 KB |

| Downloads |

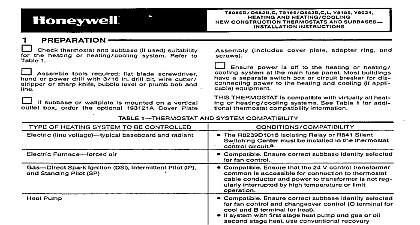

Text Preview

V8043A E F 5000 Series VALVES These valves consist of a motorized and valve assembly for controlling flow of hot water to a heat exchanger as a radiator convector finned radiator or infloor radiant coil space temperature control The V8043 series valves provide two position through control of supply water at to 300 psi operating pressure Quick Fit actuator provides easy snap on and connection to the valve assembly Electrical Rating 60 Hz 0.30 A Current Draw W 7.2 VA maximum Connection leads or screw terminal board Switch Rating 4.4A running 26.4A Inrush 60 Hz VA Pilot duty at 24 V Temperature models class F motor F 93 cid 176 C Max Temperature F 52 cid 176 C Max Limits Relative Humidity Non condensing and Storage Temperature F to 150 cid 176 F 40 cid 176 C to 65 cid 176 C non explosive Soldering Temperature F 260 cid 176 C Rubber ball plug must be away from the seat for soldering System Pressure Rating psi 2000 kPa PN20 Characteristics opening for on off application return for water hammer resist Close off Rating Flow Rating psi 3.5 Cv psi 8 Cv Pending Materials steel zinc plated steel gear Brass Material of forged brass drive shaft stem of steel ball plug of Buna N rubber seals of EPDM rubber Medium Suitable for glycol water mix up to 50 50 in closed hydronic systems Not for with oxygenated water potable water steam Use this valve in hydronic systems which not contain dissolved oxygen in the water The dissolved oxygen is found in systems that have a source of make up water causes rubber plug inside the valve to and eventually fail C US Certified to Canadian Standards and Underwriter s Laboratories Straight through Normally Closed V8043A Leadwires Leadwires and End Switch Terminal Board and End Switch V8043 SWEAT COPPER CONNECTION MODELS DIA 89 MAN OPEN NEEDED TO REMOVE COVER FOR 1 2 IN COPPER TUBING FOR 3 4 IN COPPER TUBING FOR 1 IN COPPER TUBING IN 124 MAX ON V8034F WITH TERMINAL BOARD ENCLOSURE AND V8043B VALVES THAT ARE NORMALLY OPEN IN THE DE ENERGIZED HAVE NO MANUAL LEVER TO MOUNTING INSTRUCTIONS FOR 1 2 IN CONDUIT ON MANUAL SIDE FOR V4043 V8043 1 Mounting Dimensions in in mm in Brackets 1 Disconnect power supply before wiring to prevent electrical or equipment damage 2 Normally it is not necessary to remove actuator from the valve body during If the valve must be be certain that it is with the water flow in the of the arrow Reversal of the results in damage to the gear 3 On 24V systems never jumper the coil terminals even temporarily can burn out the heat anticipator in thermostat Installing this Product 1 Read these instructions carefully Failure follow them could damage the product cause a hazardous condition 2 Check the ratings given in the and on the product to make the product is suitable for your 3 Installer must be a trained experienced technician 4 After installation is complete check out operation as provided in these Install the valve in an area with adequate to Move the manual opening lever on the of the actuator Remove the actuator cover Wire the actuator Replace the actuator motor The valve location should be in an area the temperature does not exceed the valve operating ambient and fluid temperatuare Lever V8043 normally closed valves can be manually by moving the manual lever and firmly to the MAN OPEN position pushing up to the stop The stop permits valve to be locked in the open position valve returns to automatic position when is energized Printed in Canada No 95C 10932 The valve can be mounted in any position a vertical line See Fig 2 If the valve is horizontally the actuator must be with or above the center line of the Make sure to leave enough room the actuator to remove the cover for the valve directly in the tube or pipe the coil Make sure that the flow the valve is in the direction by the arrow stamped on the body 2 Mounting Positions Copper Models Use new properly reamed pipe free dents or corrosion Place the valve on the pipe Set the opening lever to MAN OPEN before applying heat This the plug inside the valve by it from the seat Sweat the joints keeping the outer free from solder DO NOT use solder because of the high temperature required INSTALL A COMPLETE VALVE V8043 Disconnect power supply before wiring to prevent electrical or equipment damage Install valve into pipe on the return side the coil See Mounting Section Make wiring connections to valve Refer Wiring section for proper instructions Inspect the valve installation to ensure all connections and adjustments been correctly made Adjust the or controller connected to the so that the valve runs through its Make sure the valve runs and positively from closed to to closed again See Operation Checkout Sections REMOVE THE ACTUATOR FROM THE BODY See Fig 3 is not necessary to drain the hydronic if the valve body assembly remains in pipe line Switch power supply OFF Disconnect leads carefully noting the and colour of each lead Place the manual lever in the MAN position Remove actuator by fully depressing release button and lift it straight of the body PLACE MANUAL IN OPEN DEPRESS LIFT ACTUATOR UP 3 Removing Actuator from Valve Body INSTALL REPLACEMENT ACTUATOR THE VALVE BODY Align the parallel flat surfaces in shaft of valve body with in side of body i e 90 cid 176 to water See Fig 4 This makes actuator easier Wiring connections may be made either or after actuator installed on body Place the manual lever on the in the MAN OPEN position Line up motor coupling to the parallel flat in double D shaft of body and fit actuator onto the valve body that the shaft seats correctly Fig 5 Snap actuator onto body by pressing manual lever may be released but it is also automatically when the valve is operated flat surfaces with Notch on of valve body T87F CIRCULATOR ANOTHER VALVE LEADS 4 Shaft Position T87F 6 Typical wiring for V8043E V8044E SWITCH CIRCULATOR ANOTHER Tab 5 Installing Actuator 7 Typical wiring for V8043F SUPPLY PROVIDE DISCONNECT MEANS AND PROTECTION AS REQUIRED Disconnect the power supply before wiring to prevent electrical shock equipment damage All wiring must comply with local codes and Connections to the individual are shown in Fig 6 and 7 See Fig 8 14 for typical hookups If replacing a Taco Dole Flair or White 3 wire valve with a 2 wire V8043E or see Fig 15 through 27 Check that the rating of the new valve is for the application SUPPLY PROVIDE DISCONNECT MEANS AND OVERLOAD AS REQUIRED V8043A BLACK LEADWIRE TO THERMOSTAT 8 T822 Thermostat V8043A valve hookup FOR V8043E MODEL