Notifier FCM-1 Supervised Control Module Installation and Maintenance Instructions

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | notifier-fcm-1-supervised-control-module-installation-and-maintenance-instructions-4162753980.pdf |

|---|---|

| Type | |

| Size | 528.78 KB |

| Downloads |

Text Preview

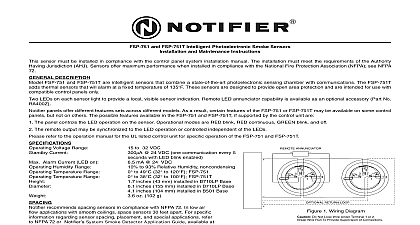

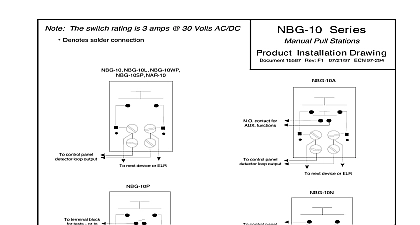

Relay Contact Ratings AND MAINTENANCE INSTRUCTIONS RATING MAXIMUM VOLTAGE LOAD DESCRIPTION A A A A A A A A VDC VDC VDC VAC VDC VDC VAC VAC L R 5ms L R 2ms PF 35 PF 35 Coded Coded Coded Coded Coded relay switch contacts are shipped in the standby state open state but may have transferred to the activated closed state during To ensure that the switch contacts are in their correct state modules must be made to communicate with the panel before circuits controlled by the module Supervised Control Module Clintonville Rd Northford CT 06472 1653 484 7161 Operating Voltage 15 to 32 VDC Current Draw 6.5 mA LED on Operating Current 390 LED flashing Supply Voltage between Terminals T3 and T4 80 Volts RMS or DC on External Supply 2 mA Maximum using internal EOL relay Range 32 to 120 0 to 49 10 to 93 Noncondensing 41 2 H x 4 W x 11 4 D Mounts to a 4 square by 21 8 deep box SMB500 Electrical Box CB500 Barrier Installing information is included as a quick reference installation Refer to the control panel installation manual for detailed information If the modules will be installed in an existing system inform the operator and local authority that system will be temporarily out of service Disconnect power the control panel before installing the modules This manual should be left with the owner user of this Description Supervised Control Modules are intended for use in intel two wire systems where the individual address of each is selected using the built in rotary switches This module used to switch an external power supply which can be a DC supply or an audio amplifier up to 80 VRMS to notifica appliances It also supervises the wiring to the connected and reports their status to the panel as NORMAL OPEN or CIRCUIT The FCM 1 has two pairs of output termination available for fault tolerant wiring and a panel controlled indicator This module can be used to replace a CMX 2 mod that has been configured for supervised wiring operation Requirements ensure proper operation this module shall be connected to a Notifier system control panels only list available from FCM 1 mounts directly to 4 square electrical boxes see 2A The box must have a minimum depth of 21 8 Surface electrical boxes SMB500 are available All wiring must conform to applicable local codes ordi and regulations When using control modules nonpower limited applications the CB500 Module must be used to meet UL requirements for the of power limited and nonpower limited termi and wiring The barrier must be inserted into a 4 x21 8 junction box and the control module must be into the barrier and attached to the junction box 2A The power limited wiring must be placed the isolated quadrant of the module barrier Figure Install module wiring in accordance with the job drawings and wiring diagrams Set the address on the module per job drawings Note Some panels support extended addressing In order to the module above address 99 on compatible systems care remove the stop on the upper rotary switch with thumb the direction shown in Figure 1A Secure module to electrical box supplied by installer as in Figure 2A When using the FCM 1 for fire fighter telephone remove Jumper J1 and discard The Jumper is on the back under the product label as shown in Figure 1A Removing switch stop 1B Jumper location 865 6 7 8 9 OF 2A Module mounting with barrier UNDER LABEL 2B 4 I56 1169 07 2001 Notifier 1 I56 1169 07 3 Typical notification appliance circuit configuration NFPA Style Y 5 Typical wiring for speaker supervision and switching NFPA Style Y MODULES TO LISTED COMPATIBLE CONTROL PANELS ONLY NEXT LINE VDC MAX PAIR RECOMMENDED PANEL OR DEVICE WIRING SHOWN IS SUPERVISED AND POWER LIMITED WIRING SHOWN IS SUPERVISED LINE VDC MAX PAIR RECOMMENDED NEXT MUST BE SUPERVISED PER NFPA MODULES TO LISTED COMPATIBLE MODULES TO LISTED COMPATIBLE CONTROL PANELS ONLY CONTROL PANELS ONLY PANEL OR DEVICE 865 6 7 8 9 VDC CIRCUIT NOT LOOP WIRE ON TERMINALS 4 BREAK WIRE RUN TO PROVIDE OF CONNECTIONS VDC POWER SUPPLY REGULATED POWER PER NFPA 70 FOR FIRE PROTECTION WITH BACKUP POLARITIES ARE IN ALARM EOL LISTED EOL RELAY ENERGIZED VDC COIL NEXT CONTROL MODULE OR END OF LINE RELAY RELAY REQUIRED FOR EACH CIRCUIT CONTROL PANELS HAVE RELAY BUILT IN AND NOT REQUIRE EXTERNAL WIRING REFER TO MANUAL SWITCHING CIRCUIT NFPA STYLE W MUST BE LISTED FOR FIRE PROTECTION REFER THE RELAY CONTACT RATING TABLE FOR MAXIMUM LOAD K EOL 865 6 7 8 9 CIRCUIT NOT LOOP WIRE AROUND TERMINALS 4 BREAK WIRE TO ENSURE OF CONNECTIONS AMPLIFIER 70.7 Vrms MAX ONLY MODELS AA 30 AA100 OR AA 120 AMPLIFIER PROVIDE WIRING SUPERVISION PER NFPA POLARITIES ARE IN ALARM NEXT CONTROL MODULE MODULE MUST RETURN FOR SUPERVISION CIRCUIT WIRING MUST BE TWISTED PAIR AS A MINIMUM NOTIFIER INSTALLATION MANUAL FOR DETAILED INFORMATION A 70.7V AUDIO AMPLIFIER IS USED TERMINALS 1 AND 2 ARE POWER LIMITED TERMINALS 3 9 ARE NONPOWER LIMITED IN THIS CASE THE CB500 BARRIER REQUIRED OTHERWISE ALL TERMINAL WIRING IS POWER LIMITED THE CB500 A LABEL INDICATING WHICH TERMINALS ARE NONPOWER LIMITED THIS MUST BE PLACED OVER THE POWER LIMITED TERMINAL INFORMATION ON NAMEPLATE LABEL PRESENT ON THE MODULE HOUSING 4 Typical fault tolerant notification appliance circuit configuration NFPA Style Z 6 Typical fault tolerant wiring for speaker supervision and switching NFPA Style Z WIRING SHOWN IS SUPERVISED POWER LIMITED NEXT LINE VDC MAX PAIR RECOMMENDED MODULES TO LISTED COMPATIBLE CONTROL PANELS ONLY PANEL OR DEVICE 865