Vesda VLC-EX-US TDS AQ IE lores pdf

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | vesda-vlc-ex-us-tds-aq-ie-lores-pdf-9621084375.pdf |

|---|---|

| Type | |

| Size | 763.32 KB |

| Downloads |

Text Preview

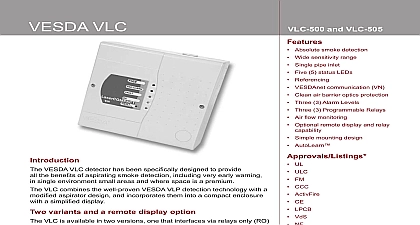

VLC EX US Suitable for Class 1 Division 2 applications Groups A B C D Absolute smoke detection Wide sensitivity range Single pipe inlet Five 5 status LEDs Referencing VESDAnet communication VN Clean air barrier optics protection Three 3 Alarm Levels Three 3 Programmable Relays Air flow monitoring Optional remote display and relay rated stainless steel enclosure Simple mounting design AutoLearn UL ULC FM approvals listings and regulatory compliance vary between VESDA models Refer to www xtralis com for the latest product approvals matrix VLC EX US VESDA VLC EX US detector has been specifically designed to provide the benefits of aspirating smoke detection including very early warning the protection of hazardous applications with a Class 1 Division 2 classification VLC EX US combines the well proven VESDA VLP detection technology with modified aspirator design and incorporates them into an IP54 rated stainless enclosure variants and a remote display option VLC EX US is available in a version that is suited for small area applications to 2000sq ft 200m and another that is suited for medium area applications to 8000sq ft 800m Each of which is available in two versions one that via relays only RO and one that interfaces via relays and VESDAnet VN version is compatible with the remote Display Module which allows the status of the detector to be reported in the most convenient location remote Display Module has 7 remote relays to support any combination signalling that may be demanded by the application The VN version allows detectors to be linked together on VESDAnet thereby allowing one to act a reference detector for other VESDA detectors VLC EX US is enclosed in a stainless steel housing which is comprised of the enclosure and the front cover main enclosure houses all the key components of the detector non serviceable items such as the main processor board and detector are mounted away from the general access area protecting them during installation and servicing process front cover includes Reset Isolate Push Button press to reset press and hold to isolate LEDs Fire Pre Alarm Alert Fault OK Reset Isolate VLC EX US it works is continually drawn through the pipe network to a central detector by a high aspirator Air entering the unit passes a flow sensor before a sample is through a dual stage dust filter The first stage removes dust and dirt from air sample before it enters the chamber for smoke detection The second ultra stage provides a clean air supply to be used inside the detection chamber to clean air barriers which protect the optical surfaces from contamination detection chamber uses a stable highly efficient laser light source and unique configuration to achieve the optimum response to a wide range of smoke When smoke passes through the detection chamber it creates light scatter is detected by the very sensitive sensor circuitry status of the detector all alarms service and fault events are monitored and with time and date stamps Status reporting can be transmitted via simple connections or across the advanced VESDAnet communications network VN only Consideration a Class 1 Division 2 installation the detector sampling network and must be located within the same protected area Detector accessories power supply etc are installed outside the classified area with wiring meeting NEC NFPA 70 requirements for Class 1 Division 2 Termination Card VN A Bias GND Reset Reset Bias LED GND LED FIRE NO FIRE C PRE ALARM NO PRE ALARM C FAULT NO FAULT C FAULT NC B Shield VESDAnet A VESDAnet A Shield VESDAnet B VESDAnet B Power Power Power Power Termination Card RO A FIRE NO FIRE C PRE ALARM NO PRE ALARM C FAULT NO FAULT C FAULT NC B Bias GND Reset Reset Bias LED GND LED Power Power Power Power Information VN Class 1 Div 2 2000ft2 200m2 VLC 205 EX US RO Class 1 Div 2 2000ft2 200m2 VLC 200 EX US VN Class 1 Div 2 8000ft2 800m2 VLC 505 EX US RO Class 1 Div 2 8000ft2 800m2 VLC 500 EX US Display relays Display no relays Relays no display number Compliance refer to the Product Guide for details compliant design installation and and Europe 44 1442 242 330 D A CH 49 4347 903 0 The Americas 1 781 740 2223 East 962 6 588 5622 Asia 86 21 5240 0077 Australia and New Zealand 61 3 9936 7000 contents of this document are provided on an is basis No representation or warranty either express or implied is made as to the accuracy or reliability of the contents of this document The manufacturer reserves the right to change designs or specifications obligation and without further notice Except as otherwise provided all warranties express or implied including without limitation any warranties of merchantability and fitness for a particular purpose are expressly excluded document includes registered and unregistered trademarks All trademarks displayed are the trademarks of their respective owners use of this document does not constitute or create a licence or any other right to use the name and or trademark and or label document is subject to copyright owned by Xtralis AG You agree not to copy communicate to the public adapt distribute transfer modify or publish any contents of this document without the express prior written consent of Xtralis no 21566 01 29984 voltage to 30 VDC consumption W quiescent 5.9 W with alarm consumption mA quiescent 245 mA with alarm rating A WHD 5 8 x 10 5 8 x 3 7 8 270 mm x 270 mm x 97 mm lbs 4.9 kg conditions 32 to 103 0 to 39 14 to 131 10 to 55 Air 4 to 140 20 to 60 10 to 95 RH non condensing network 200 Series area of Coverage 2000 sq ft 200 sq m pipe length 1 x 65 ft 20 m 2 x 50 ft 15 m Pre engineered 500 Series area of Coverage 8000 sq ft 800 sq m pipe length 1 x 260 ft 80 m 2 x 164 ft 50 m ASPIRE2 Diameter 9 16 15 mm mm Diameter 1 inch 25 mm Relays rated 2 A 30 VDC NO NO Maintenance Isolate NC NO as latching or non latching Grade 304 stainless steel IP54 access x 7 8 23.2 mm cable entries glands and blanking plugs NOT supplied termination Terminal blocks 0.2 sq mm 30 AWG sensitivity range to 6.25 obs ft 0.005 to 20 obs m setting range to 4 obs ft for UL features log Up to 12,000 events stored in FIFO format level user actions alarms and faults with time and stamp Minimum 15 minutes maximum 15 days minimum 14 days AutoLearn thresholds are NOT changed from values general input 24 VDC Mains OK or Reset Isolate obs ft obs m obs ft obs m obs ft obs m for VLC 505 EX US and VLC 205 EX US only and to be in non hazardous areas Product UL listed for use from 32 to 104 0 to 38 Product Enclosure Rating has not been evaluated by UL