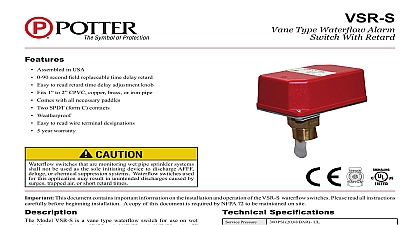

Potter VSR-S Series Waterflow Alarm Switch for Small Pipe Canada

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | potter-vsr-s-series-waterflow-alarm-switch-for-small-pipe-canada-6341028759.pdf |

|---|---|

| Type | |

| Size | 1.77 MB |

| Downloads |

Text Preview

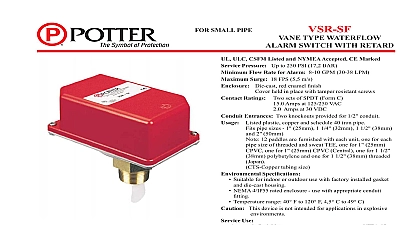

R SMALL PIPE TYPE WATERFLOW SWITCH WITH RETARD ULC CSFM Listed and NYMEA Accepted Pressure Up to 300 PSI 20,7 BAR Flow Rate for Alarm 10 GPM 38 LPM Surge 18 FPS 5,5 m s Die cast red enamel nish Ratings Two sets of SPDT Form C Amps at 125 250 VAC Amps at 30 VDC Resistive Entrances Two knockouts provided for 1 2 conduit Listed plastic copper and schedule 40 iron pipe Individual switch compartments suitable for dissimilar voltages pipe sizes 1 25mm 1 1 4 32mm 1 1 2 38mm 2 50mm 12 paddles are furnished with each unit one for each pipe of threaded and sweat TEE one for 1 25mm CPVC for 1 25mm CPVC Central one for 1 threaded Nibco and one for 1 1 2 38mm threaded Japan Speci cations Suitable for indoor or outdoor use with factory installed gasket NEMA 4 IP55 rated enclosure use with appropriate conduit die cast housing tting Temperature range 40 F to 120 F 4,5 C to 49 C Use Automatic Sprinkler One or two family dwelling Residential occupancy up to four stories National Fire Alarm Code Tamper Detects removal of cover Components Retard Switch Assembly stock no 1029030 Switch Contact SPDT Form C Contact Rating 3 Amps at 250 VAC 5 Amps at 125 VAC 1mA at 5 VDC min Terminations 8 20cm 22 AWG wire leads of a valve drain or tting which changes the direction of the ow Select the proper paddle for the pipe size and type of TEE See Fig 1 for instructions on changing the paddle The unit has a NPT bushing for threading into a non corrosive TEE See Fig 2 for TEE size type and installation Use no more than three wraps Te on tape the device into the TEE tting as shown in Fig 2 Care must be to properly orient the device for the direction of water ow vane must not rub the inside of the TEE or bind in any way The should move freely when operated by hand device can also be used in copper or plastic pipe installation with proper adapters so that the speci ed TEE tting may be installed the pipe run Do not leave cover off for an extended period of time No 1144441 must be perfomed by quali ed personnel and in with all national and local codes and ordinances hazard Disconnect power source before servicing Serious or death could result of explosion Not for use in hazardous locations Serious or death could result Model VSR S is a vane type water ow switch for use on wet systems that use 1 25mm 1 1 4 32mm 1 1 2 38mm or 50mm pipe size The unit may also be used as a sectional water ow on large systems unit contains two single pole double throw snap action switches an adjustable instantly recycling pneumatic retard The switches actuated when a ow of 10 gallons per minute 38 LPM or more downstream of the device The ow condition must exist for a of time necessary to overcome the selected retard period VSR S switches and retard device are enclosed in a general die cast housing A cover tamper switch is included to indicate removal of the cover devices may be mounted in a horizontal or vertical pipe On pipe they should be installed on the top side of the pipe they will be accessible The units should not be installed within Electric Signal Company LLC 100 Westmore Dr Units 6 7 Etobicoke ON Canada M9V5C3 Phone 888 882 1833 www pottersignal com IN USA 5401207 REV H PAGE 1 OF 6 SMALL PIPE 2 TYPE WATERFLOW SWITCH WITH RETARD 4,3MM 11 16 735 33 the device into the tee tting as shown Care must be taken to orient the device for the direction of water ow On sweat tees threaded bushings inserts or adapters are permitted unless they with the dimensions listed in the chart below The depth to the inside bottom of the tee should have the dimensions 1 Adjustment time delay is factory set at 10 seconds The delay can adjusted by rotating the retard knob from 0 to the setting 60 90 seconds time delay should be set at minimum required to prevent alarms OF FLOW TAMPER SWITCH not leave cover off extended period time SO ON POINTS DIRECTION OF NPT ON SIZES OF THE TEE BE OR PIPE 737 31 not use more than three wraps of te on tape OF 802 30A are 12 paddles furnished with each unit One for each size of threaded sweat or TEE as described in Fig 2 These paddles have raised lettering that shows the size and type of TEE that they are to be used with The proper paddle must be used paddle must be properly attached see drawing and the screw that holds the paddle be securely tightened 3 Terminal Connections Clamping Plate Terminal I N N uninsulated section of a single conductor should not be looped around terminal and serve as two separate connections The wire must be thereby providing supervision of the connection in the event that wire becomes dislodged from under the terminal 923 3 I N 4 ELECTRICAL CONNECTIONS Depth Requirement Size x 1 x 1 1 4 x 1 1 4 x 1 1 2 x 1 1 2 x 1 x 2 x 1 1 16 7 16 11 16 3 16 3 4 7 16 1 4 3 4 7 16 7 TAMPER SWITCH with cover in place 8810018 2 5 remove knockouts screwdriver at of knockouts not the center 6 out thin section of cover when both switches from one conduit DC OR AC DC OR AC ZONE ON PANEL 1146 3A The model VSR S has two switches one can be used to operate a central station proprietary or signaling unit while the other is used to operate a local audible or visual annunciator For supervised circuits see Terminal Connections drawing and caution note Fig 3 1146 4 1206 2 to the possibility of unintended discharges caused by pressure surges trapped air or short retard water ow switches that are monitoring wet pipe sprinkler systems shall not be used as the sole device to discharge AFFF deluge or chemical suppression systems IN USA 5401207 REV H PAGE 2 OF 6 SMALL PIPE TYPE WATERFLOW SWITCH WITH RETARD frequency of inspection and testing for the Model VSR S and its associated protective monitoring system should be in accordance with applicable Codes and Standards and or the authority having jurisdiction manufacturer recommends quarterly or more frequently inspector test valve usually located at the end of the most remote branch line should always be used for test purposes If there are no provisions testing the operation of the ow detection device on the system application of the VSR S is not recommended or advisable minimum ow of 10 gpm 38 Lpm is required to activate this device advise the person responsible for testing of the re protection system that this system must be tested in accordance the testing instructions detectors monthly for leaks If leaks are found replace the detector The VSR water ow switch should provide years of trouble free service retard and switch assembly are easily eld replaceable In the unlikely event that either component does not perform properly please order retard switch assembly stock 1029030 There is no maintenance required only periodic testing and inspection To prevent accidental water damage all control valves should be shut tight and the system completely drained before water ow detectors are removed