Siemens AD2-P, AD2-PR and AD2-XHR Air Duct Monitoring Housings, Installation Instructions

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | siemens-ad2-p-ad2-pr-and-ad2-xhr-air-duct-monitoring-housings-installation-instructions-7904352816.pdf |

|---|---|

| Type | |

| Size | 725.52 KB |

| Downloads |

Text Preview

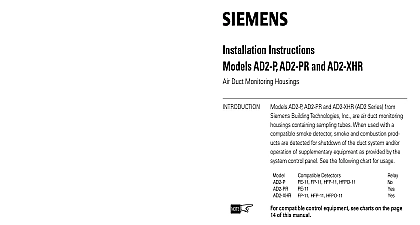

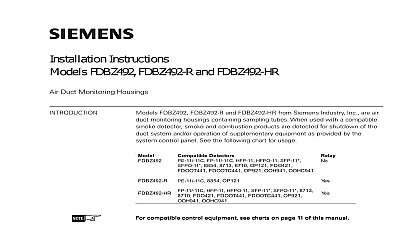

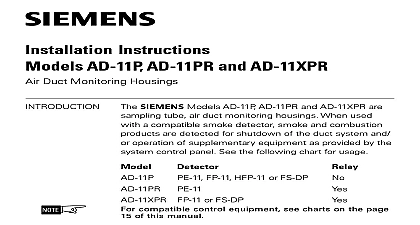

Installation Instructions AD2 P AD2 PR and AD2 XHR Duct Monitoring Housings DATA DUCT CONDITIONS AD2 P AD2 PR and AD2 XHR AD2 Series from Industry Inc are air duct monitoring housings sampling tubes When used with a compatible detector smoke and combustion products are for shutdown of the duct system and or operation supplementary equipment as provided by the system panel See the following chart for usage compat see charharharharharts on the page compat compat control equipment control equipment see c see c on the page on the page control equipment see c compatible control equipment on the page see c control equipment compat on the page of this manual of this manual of this manual of this manual of this manual Range 0OC 100OF 38OC per UL 268 268A Range AD2 PR and AD2 XHR No altitude limitations Humidity Range non condensing non freezing Duct Velocity Range ft min AD2 P AD2 PR and AD2 XHR Tube Pressure Range of Differences than 0.01 and less than 1.2 inches of water column air duct detectors are designed for detection and of products of combustion in a duct system TheyTheyTheyTheyThey not to be used for not to be used for open area prot open area prot open area protectectectectection not to be used for open area prot not to be used for not to be used for open area prot NOT USE air duct detectors with Alarm Verification 315 049708 6 Inc Inc Inc Industry Inc Inc TTTTTececececechnologies Di Di Di Division Di detector has a cover tamper removal switch Care be taken when installing the cover Squarely place the on the unit to aviod possible damage to the switch NOT SLIDE COVER INTO POSITION AD2 Series duct smoke detectors provide early detec of smoke and products of combustion present in air through an HVAC duct supply return or both These are designed to prevent the recirculation of smoke in by the air handling system fans and blowers Com systems may be shut down in the event of smoke the correct installation of a duct smoke unit please refer NFPA 72 National Fire Alarm Code NFPA 90A Standard Installation of Air Conditioning and Ventilation Systems NFPA 92A Recommended Practice for Smoke Control the Models AD2 P AD2 PR and AD2 XHR are operat a sample of air is drawn from the duct and passed the sampling chamber by means of the input tube The air sample passes through the smoke mounted in the duct housing and is exhausted back the duct through the outlet tube detector is equipped with cover removal switch SW1 instantly provides a trouble condition upon removal of clear cover For all testing and inspection with the cover the cover removal switch designated as SW1 on must be manually depressed to simulate normal AD2 P AD2 PR and AD2 XHR contain an LED indicator on the smoke detector capable of flashing either one three distinct colors green yellow or red During each flash the microprocessor based detector checks the smoke in its sensing chamber its critical smoke sensing electronics are operating Indicator Industry Inc Technologies Division 315 049708 5 on the results of these checks the LED indicator as follows DUCT 1 Mounting of Duct Housing A CLOSED SYSTEM NO EXHAUST AIR INTAKE DUCT DUCT B PROVISION FOR EXHAUSTING PERCENTAGE OF RETURN AIR AIR INTAKE AIR DUCT DUCT C RETURN AIR UNDER POSITIVE PRESSURE SEPARATE BLOWER AIR INTAKE AIR AIR DUCT DUCT 2 Locations in Duct Systems Industry Inc Technologies Division 315 049708 5 THE AIR DUCT HOUSING on Duct System guideline contains general information on duct smoke installation but does not preclude the NFPA listed Siemens Industry Inc assumes no for improperly installed duct detectors To the correct installation position for an AD2 Series smoke detector the following factors must be consid A uniform non turbulent laminar airflow between 100 ft to 4,000 ft min must be present in the HVAC duct determine duct velocities examine the engineering that define the expected velocities or use Alnor model 6000AP velocity meter or equivalent To minimize the impact of air turbulence and stratifica on performance a duct smoke detector should be as far as possible downstream from any obstruc i e deflector plates elbows dampers etc In all confirmation of velocity and pressure differen within specifications is required pressure differential between the input sampling pressure tube and outlet low pressure tube for AD2 Series smoke duct detector should be greater 0.01 inches of water and less than 1.2 inches of a code compliant location supply or return side both for the installation of the duct unit that will easy access for viewing and serviceability When installing on the return side install duct units prior the air being exhausted from the building or diluted outside air When installing duct smoke units downstream of filters occurring in the filters will be detected but if the become blocked insufficient air flow through the unit will prevent the correct operation of the duct Duct units installed in the supply air side may upstream equipment and or filters Where possible install duct detectors upstream of air and downstream of dehumidifiers Industry Inc Technologies Division 315 049708 5 To prevent false alarms the duct detector should not be in areas of extreme high or low temperatures areas where high humidity exists or in areas where duct may contain gases or excessive dust Preparation AD2 Series Housings come with an installation kit that the following items Tube Installation Short return outlet sampling tube Stopper Two 12 x 3 4 sheet metal screws Mounting template packaged separately mounting template from the installation kit Remove backing from the mounting template and affix it to the at the desired location Using the template as a guide 2 mounting holes 3 32 2.5mm for the 12 X 3 4 metal screws packaged in the installation kit Drill or 2 1 32mm holes for input sampling and outlet using the template as a guide Clean all holes AD2 Series duct smoke detectors use a specially sampling tube which may be ordered separately in of four standard lengths duct widths of 6 to 1.0 duct widths of 1.0 to 3.0 duct widths of 3.0 to 5.0 support duct widths of 5.0 to 10.0 requires support model is supplied as two 5 ft sections with a coupling is required for installation model is manufactured with a different number and of sampling holes Only the specific tube must be used the specified duct width sampling tubes are steel tubes with air intake holes the entire length of the tube These tubes can be cut length and must span at least 80 the width of the du