Silent Knight IDPpduct isheet

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | silent-knight-idppduct-isheet-7481652903.pdf |

|---|---|

| Type | |

| Size | 1.10 MB |

| Downloads |

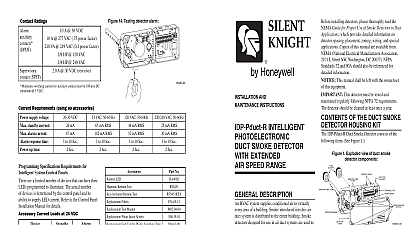

Text Preview

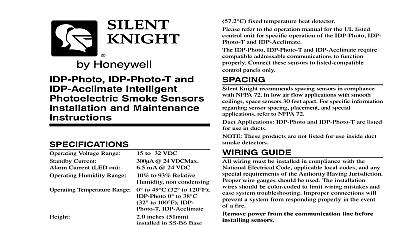

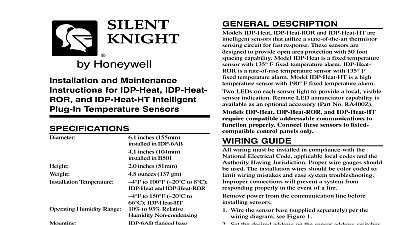

Accessories LED Remote Test Remote Test Filters Test Magnet Photo Insect Screen End Cap for Plastic Sampling Tube End Cap for Metal Sampling Tubes Photoelectric Sensor Board Power Board w relay No 12 Testing detector alarm Meridian Circle Grove MN 55369 4927 800 328 0103 763 493 6475 2005 Silent Knight refer to insert for the Limitations of Fire Alarm Systems keep your equipment in excellent working order ongoing maintenance is required per the manufacturer recommendations and UL and NFPA At a minimum the requirements of Chapter 7 of NFPA 72 the National Fire Alarm Code shall be followed A preventative maintenance should be arranged through the local manufacturer representative Though smoke detectors are designed for long life they may fail at any Any smoke detector fire alarm equipment or any component of that system which fails shall be repaired or replaced as soon as possible Statement device complies with part 15 of the FCC Rules Operation is subject to the following two conditions 1 This device may not cause harmful in and 2 this device must accept any interference received including interference that may cause undesired operation This equipment has been tested and found to comply with the limits for a Class B digital device pursuant to Part 15 of the FCC Rules These are designed to provide reasonable protection against harmful interference in a residential installation This equipment generates uses can radiate radio frequency energy and if not installed and used in accordance with the instructions may cause harmful interference to ra communications However there is no guarantee that interference will not occur in a particular installation If this equipment does cause interference to radio or television reception which can be determined by turning the equipment off and on the user is encouraged to to correct the interference by one or more of the following measures Reorient or relocate the receiving antenna Increase the separation between the equipment and receiver Connect the equipment into an outlet on a circuit different from that to which the receiver is connected Consult the dealer or an experienced radio TV technician for help OF THE DUCT SMOKE HOUSING KIT IDP Pduct Duct Smoke Detector consists of the fol items See Figure 1 1 Exploded View Of Smoke Detector Components HOLES TUBE TUBE SAMPLING TUBE SCREW BOARD STRIP BOARD MOUNTING Of The Duct Smoke Detector Complete duct smoke detector assembly with sensor Two 10 x 1 1 sheet metal mounting screws Two sampling tube filters One test magnet Drilling template Two foam gaskets Four 6 self tapping mounting screws for the sam tube and optional exhaust tube extension One sampling tube end cap One plastic sampling tube One 8 self tapping screw for plastic sampling tube A detector sensor board DOES NOT need to be separately For ducts over 11 feet 0.46m longer sampling must be ordered to complete the installation They be the correct length for the width of the duct where will be installed See Table 1 on page 3 to determine sampling tube required for different duct widths OF DUCT DETECTORS National Fire Protection Association has established DUCT DETECTORS MUST NOT BE USED AS SUBSTITUTE FOR OPEN AREA DETECTOR as a means of providing life safety Nor they a substitute for early warning in a building fire detection system is strongly recommended that the user read NFPA 90A 72 and 101 device will not operate without electrical power Fire may cause an interruption of power The sys safeguards should be discussed with your local fire specialist INTELLIGENT SMOKE DETECTOR EXTENDED SPEED RANGE installing detectors please thoroughly read the Guide for Proper Use of Smoke Detectors in Duct which provides detailed information on spacing placement zoning wiring and special Copies of this manual are available from National Electrical Manufacturers Association L Street NW Washington DC 20037 NFPA 72 and 90A should also be referenced for de information This manual shall be left with the owner user this equipment This detector must be tested and main regularly following NFPA 72 requirements The should be cleaned at least once a year DESCRIPTION HVAC system supplies conditioned air to virtually ev area of a building Smoke introduced into this air duct is distributed to the entire building Smoke detec designed for use in air duct systems are used to sense presence of smoke in the duct IDP Pduct air duct smoke detector is a photoelectric This smoke detection method combines with an housing design that samples air passing through duct and allows detection of a developing hazardous When sufficient smoke is sensed an alarm is initiated at the fire control panel monitoring the and appropriate action can be taken to shut off blowers and change over air handling systems etc can prevent the distribution or it can isolate toxic and fire gases throughout the areas served by the system LEDs on each detector may illuminate if programmed the system control panel to provide a local alarm in There is also a remote alarm output for use with devices The IDP Pduct has remote test capability the RTS451 RTS451KEY Remote Test Station For ducts greater than 11 feet 0.46m in width to sections 4 4.1 and 4.2 Secure The Detector Housing To The Duct the foam gaskets over the tube bushings as shown Figure 3 Use the two 11 long sheet metal screws to the detector housing to the duct Do not overtighten the screws Sampling Tube Installation for Ducts Greater 11 Feet 0.46m Wide sampling tube is identified by a series of air inlet on the tube A plastic tube is included for ducts up 11 feet 0.46m wide All other lengths must be pur separately Order the correct length as specified Table 1 for width of the duct where it will be installed is recommended that the sampling tube length extend least 2 across the duct width for optimal performance exhaust tube is molded onto the base of the duct and the A2440 00 Exhaust Tube Extension is as an accessory in those cases where the molded port does not extend at least 2 inches 50mm the duct sampling tube is always installed with the air inlet facing into the air flow To assist proper installa the tube mounting flange is marked with an arrow sure the sampling tube is mounted so that the arrow into the air flow see Figure 4 Figure 5 shows the combinations of tube mounting configurations respect to air flow Mounting the detector housing in vertical orientation is acceptable provided that a metal tube is used and the air flows directly into the tube holes as indicated in Figure 4 Installation For Ducts Greater Than 11 0.46m But Less Than 8 Feet 2.4m Wide If the tube is longer than the width of the air duct a 3 19mm hole in the duct opposite the hole cut for the sampling tube Make sure the hole 1 to 2 25 to 50mm below the inlet hole on the side of the duct to allow moisture drainage from the detector If the tube is shorter than the of the air duct install the end cap into the sam tube as shown in Figure 4 Sampling tubes over 2 Plastic sampling tube connected to duct detector device will not sense smoke unless the ventilation is operating 4.1 4.2 Installation for ducts more than 8 feet order to function properly this detector must be in according to the instructions Do not exceed the or ambient specifications or the detector will function properly This detector must be protected the elements SEQUENCE 1 Verify duct air flow direction and velocity 2 2 Drill the mounting holes 2 2.1 Install the sampling t