System Sensor BEAM200 and BEAM200S Manual

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | system-sensor-beam200-and-beam200s-manual-7280439516.pdf |

|---|---|

| Type | |

| Size | 2.08 MB |

| Downloads |

Text Preview

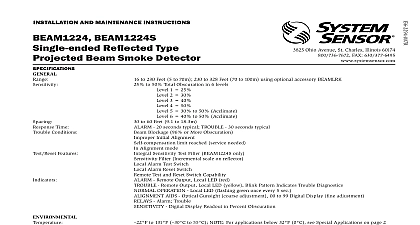

I Ohio Avenue St Charles Illinois 60174 Fax 630.377.6495 AND MAINTENANCE INSTRUCTIONS 1 25 2 30 3 40 4 50 5 30 to 50 Acclimate 6 40 to 50 Acclimate BEAM200S Reflected Type Beam Smoke Detector Time Conditions Features 7 Operation to 230 Feet 5 to 70m 230 to 328 Feet 70 to 100m using optional accessory BEAMLRK to 50 Total Obscuration in 6 levels to 60 Feet 9.1 to 18.3m 20 seconds typical TROUBLE 30 seconds typical Blockage 96 or More Obscuration Initial Alignment limit reached service needed Alignment mode Sensitivity Test Filter BEAM200S only requires additional external power supply Filter Incremental scale on reflector Alarm Test Switch Alarm Reset Switch Test and Reset Switch Capability Remote Output Local LED red Remote Output Local LED yellow Blink Pattern Indicates Trouble Diagnostics OPERATION Local LED flashing green with communication AIDS Optical Gunsight coarse adjustment 00 to 99 Digital Display fine adjustment Digital Display Readout in Percent Obscuration isolators provide style 7 operation may be disabled via shunts on circuit board to 131 to 55 NOTE for applications below 32 0 see Special Applications section of this manual to 93 RH Non condensing Weight Size Angle Trim Ring unit 3.9 lbs 1.77 kg 10.5 6.5 381mm 267mm 165mm only without optional accessories Terminal Blocks 12 to 22AWG Horizontal and Vertical be painted using enamel or acrylic type paints Current Supply BEAM200S only VOLTAGE 15 to 32 VDC Output alarm to 32 VDC Standby Alarm LED on Trouble LED on Alignment Max 1 communication every 5 sec LED flashing SLC 24 V Max Max Max 0.5A Max 15 to 32 VDC NOTE Output voltage same as device input voltage 15mA maximum 6mA minimum NOTE Output current is limited by 2.2Kohm resistor INSTALLING thoroughly read this manual and applicable sections of System Sensor Reflected Beam Detector Application Guide BMAG240 This is available online at www systemsensor com DESCRIPTION Sensor Model BEAM200 BEAM200S is a long range projected beam detector designed to provide open area protection It is to be used with compatible control panels only The detector consists of a transmit unit and a reflector When the obscuration reaches alarm thresh chosen at the transmitter receiver unit the detector generates an alarm Complete blockage of the beam causes a trouble signal Slow changes obscuration due to a build up of dirt or dust on the lens of the detector are for by a microcontroller that continuously monitors the signal and periodically updates the alarm and trouble thresholds When the circuit reaches its limit the detector generates a trouble indicating the need for service LEDs on the detector indicate the current status a red LED for alarm a LED for trouble and a blinking green LED for standby operation Note panel controls the status of the red and green LEDs The local reset but is accessible by removing the outer paintable trim ring The yellow LED blink in specific patterns to provide a diagnostic aid when diagnosing the of a trouble signal It will also blink the amount of drift compensation has been used at the conclusion of the test Trouble signals automati reset upon removing the cause of trouble Red and yellow LEDs can be connected to the remote Alarm and Trouble outputs These outputs the functions of the detector red and yellow LEDs In addition to these there is a dual digital display that reads 00 to 99 This display is to indicate the signal strength of the beam in alignment mode and to the sensitivity setting of the detector in percent obscuration when the sensitivity of the detector No additional equipment is needed for of the beam APPLICATIONS to the inherent capabilities of projected type beam detectors they are installed in locations where spot type detection is impractical Projected beam smoke detectors are ideally suited for environmental conditions might include high ceilings dusty and dirty environments or environ that experience temperature extremes Often these conditions present problems for the installation of spot type detectors and even greater for their proper maintenance Due to the inherent flexibility of locations and large coverage area of projected type beam detectors the conditions above can be addressed or minimized examples of applications for beam detectors might include freezers air hangars cold storage warehouses shipping warehouses enclosed park facilities sporting arenas and stadiums concert halls barns or stables of these environments might be considered too hostile for spot type detectors If the environment is considered to be hostile then the colder threshold settings should be used installing the transmitter receiver unit or reflector in these types of special consideration should be given to ensure proper operation the beam detector The beam detector should not be installed in environ where heavy condensation or icing is likely Condensation or icing of reflector surface or the outer surface of the transmitter receiver unit will the light beam resulting in a false alarm If elevated humidity levels rapidly changing temperatures can be expected then condensation will form and the application should not be considered acceptable for the detector The beam detector should not be installed in locations where transmitter receiver unit the reflector or the optical pathway between may be exposed to outdoor conditions such as rain snow sleet or fog conditions will impair the proper operation of the detector and must avoided ACCESSORIES following accessories can be purchased separately for use with this beam BEAMLRK allows System Sensor reflected beam detectors to be installed separations between 230 and 328 feet 70 to 100 meters At these distances 8 reflectors must be used to provide enough reflected infrared light kit includes 3 additional reflectors with new test scale legends The re included with the transmitter receiver unit is the fourth reflector to be This kit is not compatible with the multi mount kit BEAMMMK BEAMMMK allows System Sensor reflected beam detectors and reflec to be mounted to either a vertical wall or the ceiling The kit allows for alignment range in cases where the detector and reflector cannot mounted within 10 of each other The kit includes the hardware neces to mount either a single transmitter receiver unit or a single reflector mount the transmitter receiver the surface mount kit BEAMSMK must be used If the transmitter receiver and the reflector require additional range two kits are required The kit is not compatible with the long reflector kit BEAMLRK BEAMSMK allows System Sensor reflected beam detectors to be mounted surface wiring is used This kit must be used when mounting the trans unit with the multi mount kit BEAMMMK 6500 MMK provides a heavy duty multi mount bracket for installations to building movement or vibration It offers similar tilt and swivel flex found on the BEAMMMK To mount the transmitter receiver to the the surface mount kit 6500 SMK must be used 6500 SMK allows the transmitter receiver to be mounted to the 6500 heavy duty multi mount kit BEAMHK allows the transmitter receiver unit to operate in environments to the formation of condensation Condensation forming on the beam unit may result in trouble or false alarm conditions BEAMHK will the likelihood of condensation by maintaining the unit at a temperature is slightly higher than the surrounding air Please refer to the BEAMHK manual for operation instructions BEAMHKR allows the reflector to operate in environments prone to the of condensation Condensation forming on the reflector may