System Sensor SA DS2475RAR and DS2475WAR Manual

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | system-sensor-sa-ds2475rar-and-ds2475war-manual-5782049316.pdf |

|---|---|

| Type | |

| Size | 664.46 KB |

| Downloads |

Text Preview

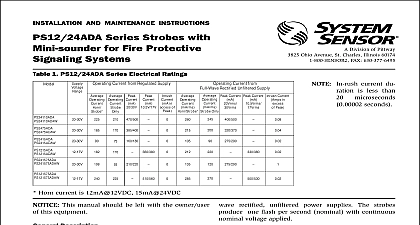

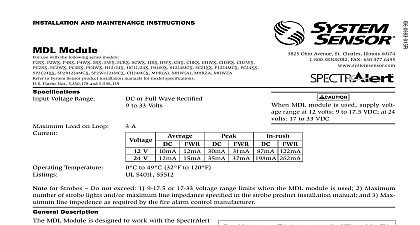

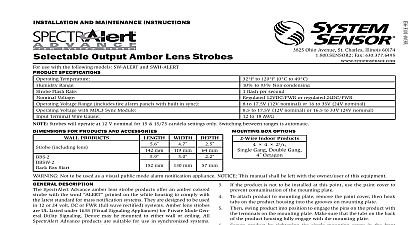

INSTALLATION AND MAINTENANCE INSTRUCTIONS Dual Strobe use with the following 24 volt models Side Lens Color Side Lens Color Color for White for Red colors for Amber and for Red Range module Rate Temperature Output to 30 Volts DC or Full Wave Rectified to 30 Volts DC or Full Wave Rectified Flash Per Second F to 120 F 0 C to 49 C candela S3593 Strobe Description SpectrAlert series notification appliances are designed to meet the of NFPA The National Fire Alarm Code and UL Also check your local Authority Having Jurisdiction for other codes or standards may apply SpectrAlert DS2475 Strobe can be installed in systems using 24 volt having DC or full wave rectified FWR power supplies The mod can also be installed in systems requiring synchronization module required or systems that do not require synchronization no module This manual shall be left with the owner user of this equipment Supply Considerations typically supply DC filtered voltage or FWR full wave rectified The system design engineer must calculate the number of units in a zone based on the type of panel supply Be certain the sum of the device currents do not exceed the current capability of the panel are based on using the device current found in the subsequent and must be the current specified for the type of panel power sup used Sizes designer must be sure that the last device on the circuit has sufficient to operate the device within its rated voltage When calculating voltage available to the last device it is necessary to consider the volt drop due to the resistance of the wire The thicker the wire the less voltage drop Generally for purposes of determining the wire size nec for the system it is best to consider all of the devices as the end of the supply circuit simulates case wire size resistance AWG solid AWG solid AWG solid AWG solid 8 ohms 1,000 ft 5 ohms 1,000 ft 3 ohms 1,000 ft 2 ohms 1,000 ft Assume you have 10 devices on a zone and each requires 50 average and 2000 Ft of 14 AWG wiring total length outgoing The voltage at the end of the loop is 0.050 amps per device x devices x 3 ohms 1,000 ft x 2000 ft 3 volts drop Ohio Avenue St Charles Illinois 60174 FAX 630 377 6495 Patent Nos 5,593,569 5,598,139 6,049,446 same number of devices using 12 AWG wire will produce only 2 volts The same devices using 18 AWG wire will produce 8 volts drop your panel manufacturer specifications as well as SpectrAlert voltage range to determine acceptable voltage drop If class wiring is installed the wire length may be up to 4 times single wire length in this calculation Draws Per Strobe CURRENT mA CURRENT mA RUSH CURRENT mA Models Models Models FWR DC FWR DC FWR 220 140 191 115 174 FWR DC FWR DC FWR 560 450 570 420 620 FWR DC FWR DC FWR 230 220 290 290 370 Operation Non Synchronized Devices 1A Powered by a 2 wire circuit NEXT EOL Reversing polarity from power supply will stop powering one and start powering the other 1B Strobes in tandem Supply power must be for proper operation NEXT OR EOL 2 Powered by a 4 wire circuit to provide independent left and right strobe operation Remove factory installed see Figure 1B Strobes must be powered continuously for proper operation STROBE SUPPLY NEXT EOL 3 Synchronizing strobes using MDL you would prefer to switch the lens colors the strobe modules are field Fig 4 reverse the strobe module insert screwdriver as shown in Fig 4 to snap While pushing in the screwdriver pull back on the strobe Hinge the strobe module disengage the Locking Rib and lift the away from the mounting plate Turn the module so that it is down from its original position re insert the module into the plate be sure to insert the Locking Rib into the slot and press module into the mounting plate The strobe module will make a when it has locked into place Turn entire assembly so that the are on the bottom The unit can now be mounted 4 Reversing the strobe module SCREWDRIVER REMOVE SCREWDRIVER SCREWDRIVER STROBE SUPPLY NEXT EOL unit can be mounted to a single gang back box or to a 4 x 4 back using the mud ring provided NEXT EOL NEXT EOL BACK BOX RIB SCREWDRIVER SCREWDRIVER Complete field wiring Align dual strobe over back box secure with screws HEAD refer to insert for the Limitations of Fire Alarm Systems Limitations of Strobes strobe will not work without power The strobe gets its power from the fire security panel the alarm system If power is cut off for any reason the strobe will not provide the visual warning Strobes must be powered continuously for horn operation signal strobe may not be seen The electronic visual warning signal uses an extremely reliable flash tube It flashes at least once every second The strobe must not be installed in direct or areas of high light intensity over 60 foot candles where the visual flash might be dis or not seen The strobe may not be seen by the visually impaired signal strobe may cause seizures Individuals who have positive photic response to visual with seizures such as persons with epilepsy should avoid prolonged exposure to environ in which strobe signals including this strobe are activated signal strobe cannot operate from coded power supplies Coded power supplies produce power The strobe must have an uninterrupted source of power in order to operate cor System Sensor recommends that the horn and signal strobe always be used in combination that the risks from any of the above limitations are minimized Sensor warrants its enclosed strobe or strobe to be free from defects in materials and work under normal use and service for a period of three years from date of manufacture Sensor makes no other express warranty for this strobe No agent representative dealer employee of the Company has the authority to increase or alter the obligations or limitations of Warranty The Company obligation of this Warranty shall be limited to the repair or replace of any part of the strobe which is found to be defective in materials or workmanship under use and service during the three year period commencing with the date of manufacture phoning System Sensor toll free number 800 SENSOR2 736 7672 for a Return number send defective units postage prepaid to System Sensor Returns RA 3825 Ohio Avenue St Charles IL 60174 Please include a note the malfunction and suspected cause of failure The Company shall not be obligated to or replace units which are found to be defective because of damage unreasonable use mod or alterations occurring after the date of manufacture In no case shall the Company be for any consequential or incidental damages for breach of this or any other Warranty or implied whatsoever even if the loss or damage is caused by the Company negli or fault Some states do not allow the exclusion or limitation of incidental or consequential so the above limitation or exclusion may not apply to you This Warranty gives you spe legal rights and you may also have other rights which vary from state to state Limited Warranty This equipment has been tested and found to comply with the limits for a Class A digital pursuant to part 15 of the FCC Rules These limits are designed to provide reasonable pro against harmful interference when the equipment is operated in a commercial environment equipment generates uses and can radiate radio frequency energy and if not installed and in accordance with