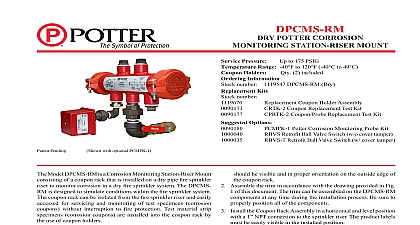

Potter PCMS-RM Riser Mount Corrosion Monitoring Station

File Preview

Click below to download for free

Click below to download for free

File Data

| Name | potter-pcms-rm-riser-mount-corrosion-monitoring-station-7043691852.pdf |

|---|---|

| Type | |

| Size | 1.24 MB |

| Downloads |

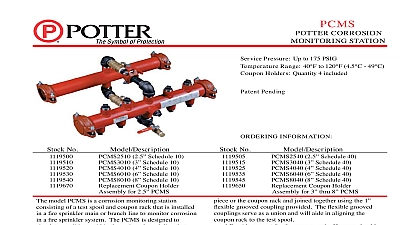

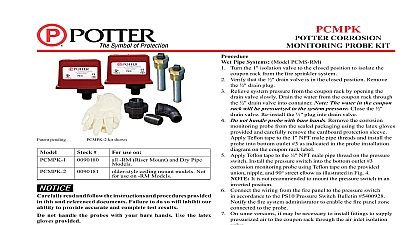

Text Preview

Features Allows easy access to measured and weighed brass and steel strips to gauge decay rate without opening or disabling system Sight glass allows easy viewing of test strips without opening Suitable for use on wet or dry systems Provides convenient location for mounting optional corrosion probe Provides isolation valves to allow testing water sampling and replacement without opening or disabling system Model PCMS RM is a Corrosion Monitoring Station Riser Mount of a coupon rack that is installed on fire sprinkler riser to corrosion in a fire sprinkler system The PCMS RM is designed simulate conditions within the fire sprinkler system The coupon can be isolated from the fire sprinkler riser and easily accessed for and monitoring of test specimens corrosion coupons without to fire protection Test material strip specimens corrosion are installed into the coupon rack using coupon holders The can be used on wet or dry pipe systems optional PCMPK 1 contains a corrosion monitoring probe pressure switch that provides notification to the fire sprinkler when there may be an excessive amount of corrosion place in the sprinkler piping The corrosion monitoring probe has precision thin wall thickness which will eventually corrode through the system pressure to enter into the probe and actuate the switch When the pressure switch is wired to the building fire panel a trouble or supervisory signal is generated notifying the administrator This is the notification to remove the test that were installed at the same time as the probe for analysis the condition of the sprinkler piping The corrosion monitoring is a single use device and must be replaced upon the installation new test coupons CPRTK2 Coupon Probe Replacement Test Kit contains the components to remove replace and forward for analysis coupons and water sample from a PCMS RM The probe is not for analysis It allows the fire sprinkler administrator leave the coupons in the system until the probe activates the pressure Specifications Pressure Up to 250 PSIG Holders to 120 4.5 to 49 2 included PAGE 1 OF 3 Corrosion Monitoring Station Riser Mountfor Wet or Dry Pipe Sprinklers5401180 REV G 4 20Potter Electric Signal Company LLC St Louis MO Tech Support 866 956 0988 Customer Service 866 572 3005 www pottersignal comfirealarmresources com See Fig 1 The PCMS RM is assembled in two sections to be joined by the attached 1 union to allow for quick installation Install the unit on the system of any control valve Install the unit in the vicinity of the riser when it is installed on a main horizontal feed The contractor shall supply and install a 1 NPT female connection to the sprinkler system riser or supply main as determined by the engineer or Using the lower 1 union connection pointing in the up position connect the lower sub assembly section with the isolation and drain valve to previously installed 1 NPT male connection NOTE Install this sub assembly in a horizontal and level position Make sure that the isolation is in the closed position Attach the upper coupon rack sub assemble section union to the previously installed lower section union and tighten union fitting The product and sight glass shall be visible in the installed position The contractor shall verify that the corrosion monitoring station has the appropriate coupons probes as required by the engineer or designer shall be made by viewing the coupons probes through the sight glass end of the PCMS RM corrosion monitoring station The corrosion monitoring station shall be installed in a horizontal and level position It may be necessary to exchange the location of the sight and the blank end cap so the inside of the coupon rack is visible through the sight glass for the PCMS RM the PCMS RM in Service on a Wet Pipe System With the coupon rack isolation valve closed to the system and the coupon rack drain valve closed and plugged pre charge the coupon rack with through the air inlet isolation valve to approximately the system water pressure Open the coupon rack isolation valve and check the water level in the coupon rack through the end sight glass For wet systems which have a vent to removed trapped air per NFPA requirements relieve air pressure to allow monitoring station to fill with water simulating a sprinkler filled with water For wet system which do not have air vents installed to relieve trapped air relieve air pressure to allow station to be more filled with water to simulate trapped air pockets Add additional air through the air inlet isolation valve to lower the water level or relieve air to raise the water to the correct level Close the air inlet isolation ball valve after the correct water level has been maintained the PCMS RM in Service on a Dry Pipe System Close the air isolation valve Open the coupon rack isolation valve Verify monitoring station is not filled with water through sight glass On dry only a small amount of water from flow testing should be allowed in the bottom of the corrosion station simulating filling and draining trapping of minimal residual water Be sure to leave the coupon rack isolation valve open to the fire sprinkler system Verify that all valves are in the correct position and the corrosion station is free of any leaks Fill out the coupon envelopes being sure to note installation date Retain envelopes to be returned analysis after required amount of time or when optional PCMPK 1 probe activates the pressure switch PAGE 2 OF 3 REV G 4 20Potter Electric Signal Company LLC St Louis MO Tech Support 866 956 0988 Customer Service 866 572 3005 www pottersignal comPCMS RMPotter Corrosion Monitoring Station Riser Mountfor Wet or Dry Pipe Sprinklersfirealarmresources com 1 2 VALVE OR PLUG RISER 1181 1 3 INLET END CAP AND SIGHT GLASS RACK HOLDER LABEL INLET ISOLATION CLOSED CONNECTION SUPPLIED GLASS END ON END FOR VISIBILITY VALVE CLOSED 3 minimum clearance required to remove coupon from coupon rack RACK NORMAL NPT RISER SUPPLIED Information Corrosion Monitoring Station Mount for Wet or Dry Pipe Coupon Holder Replacement Test Kit Replacement Test Kit No Corrosion Monitoring Probe Kit 0090180 Ball Valve Switch Tamper Switch Kit for RBVS No PAGE 3 OF 3 Corrosion Monitoring Station Riser Mountfor Wet or Dry Pipe Sprinklers5401180 REV G 4 20Potter Electric Signal Company LLC St Louis MO Tech Support 866 956 0988 Customer Service 866 572 3005 www pottersignal comfirealarmresources com